Method for preparing mesoporous silica molecular sieve fiber

A mesoporous silica and molecular sieve technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of difficult control of the diameter and length of silica molecular sieve fibers, harsh reaction conditions, etc. The effect of easy operation, high specific surface area and simple process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

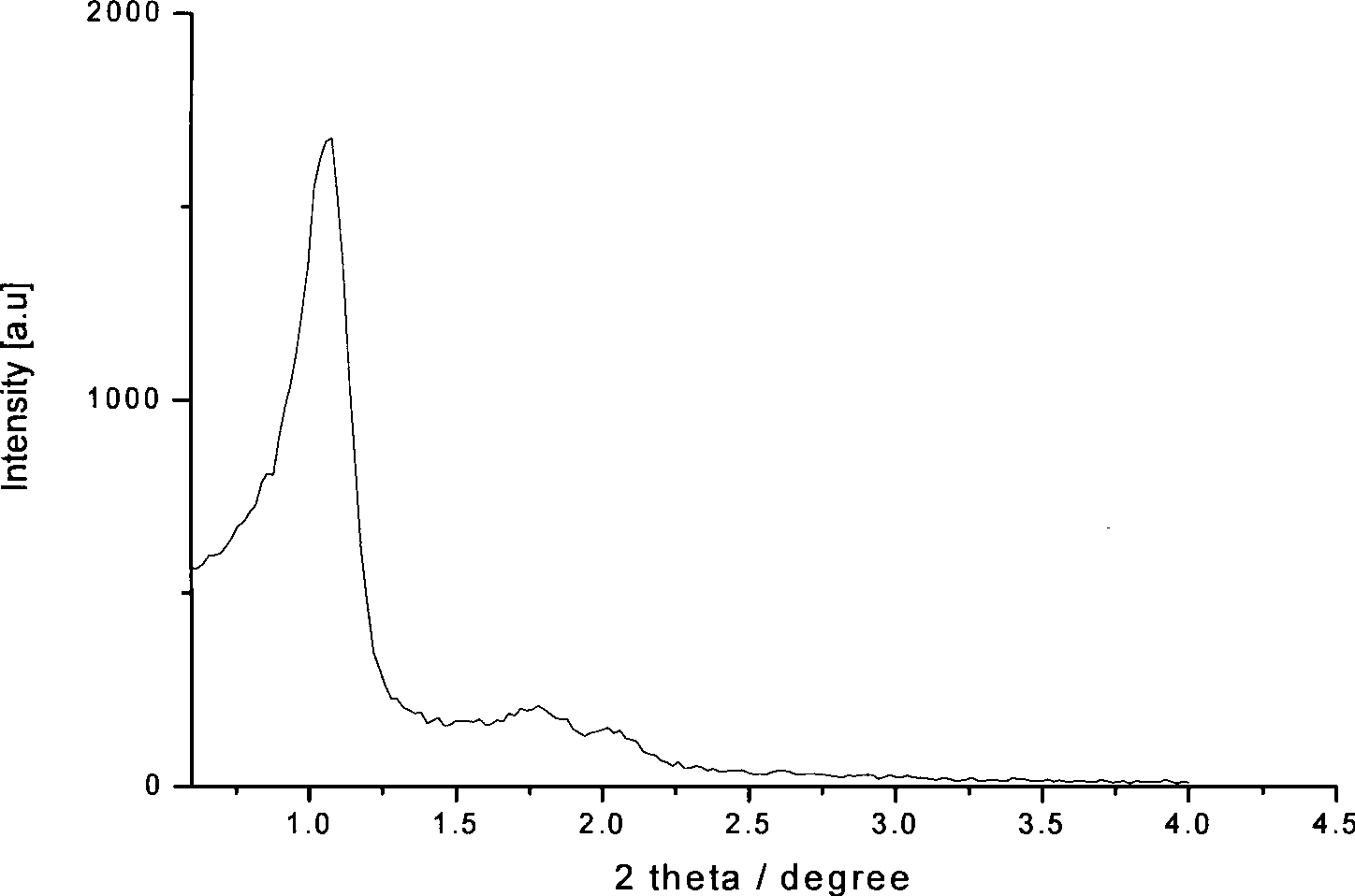

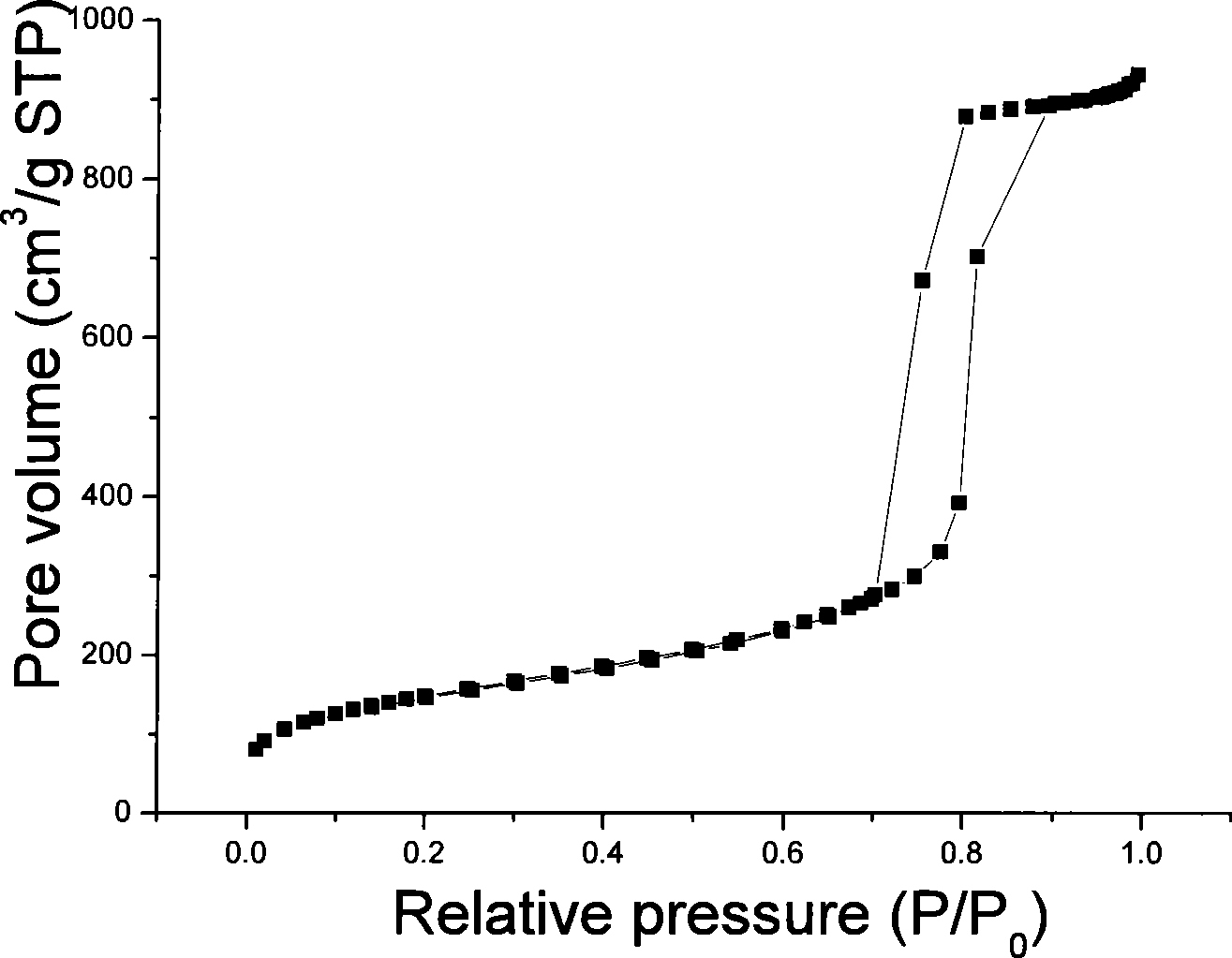

[0020] 0.3 g of Pluronic P123 (EO 20 PO 70 EO 20 ) and 2.5 grams of KCl and 0.6 grams of absolute ethanol were dissolved in 35 grams of 2mol.L -1 In the hydrochloric acid aqueous solution, after the surfactant, ethanol and sodium chloride are completely dissolved, further add 2.08 grams of tetraethyl orthosilicate TEOS into the mixed solution, and the solution is stirred at 40°C for 15 minutes and then stands still. Glue chemical process and cooperative self-assembly process to form mesoporous silica molecular sieve fibers. After the material was hydrothermally treated at 100°C for 24 hours, it was cooled to room temperature, filtered, dried in air, and finally fired at 550°C for 6 hours to remove the surfactant. figure 1 It is the scanning electron microscope figure of the sample of embodiment 1, and the sample observed by SEM is a mesoporous silica molecular sieve fiber, and the diameter of the fiber is 200nm, and the length is 150um; the XRD test shows that the sample ha...

Embodiment 2

[0022] 0.3 g of Pluronic F127 (EO 106 PO 70 EO 106 ) and 2.5 grams of KCl and 1.6 grams of absolute ethanol were dissolved in 35 grams of 2mol l.L -1In the hydrochloric acid aqueous solution, after the surfactant, ethanol and potassium chloride are completely dissolved, further add 2.08 grams of tetraethyl orthosilicate TEOS into the mixed solution, and the solution is stirred at 60°C for 20 minutes and then stands still. Glue chemical process and cooperative self-assembly process to form mesoporous silica molecular sieve fibers. After the material was hydrothermally treated at 100°C for 24 hours, it was cooled to room temperature, filtered, dried in air, and finally subjected to high-temperature calcination at 550°C for 4 hours to remove the surfactant. The sample observed by SEM is a mesoporous silica molecular sieve fiber with a diameter of 100nm and a length of 300um; figure 2 The X-ray diffraction spectrum of the sample obtained in Example 2, XRD test shows that the ...

Embodiment 3

[0024] 0.3 g of F108 (EO 132 PO 60 EO 132 ) and 3.2 grams of KCl and 0.8 grams of absolute ethanol were dissolved in 40 grams of 2mol l.L -1 In the hydrochloric acid aqueous solution, after the surfactant, ethanol and sodium sulfate are completely dissolved, further add 2.5 grams of tetraethyl orthosilicate TEOS into the mixed solution, and the solution is stirred at 40°C for 15 minutes, then stands still, and passes through sol, gel Chemical process along with cooperative self-assembly process to form mesoporous silica molecular sieve fibers. After the material was hydrothermally treated at 120°C for 36 hours, it was cooled to room temperature, filtered, dried in air, and finally subjected to high-temperature calcination at 550°C for 6 hours to remove the surfactant. The sample observed by SEM is a mesoporous silica molecular sieve fiber with a diameter of 250nm and a length of 3000um; XRD test shows that the sample has a two-dimensional hexagonal mesoporous structure. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com