Purifying method for nitric oxide gas with 3N purity

A nitric oxide and purification method technology, which is applied in the direction of nitric oxide, nitrogen oxides/oxyacids, etc., can solve the problems of high impurity content, consumption of nitric oxide, hidden dangers, etc., and achieve simple operation process and inhibition of oxidation reaction , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

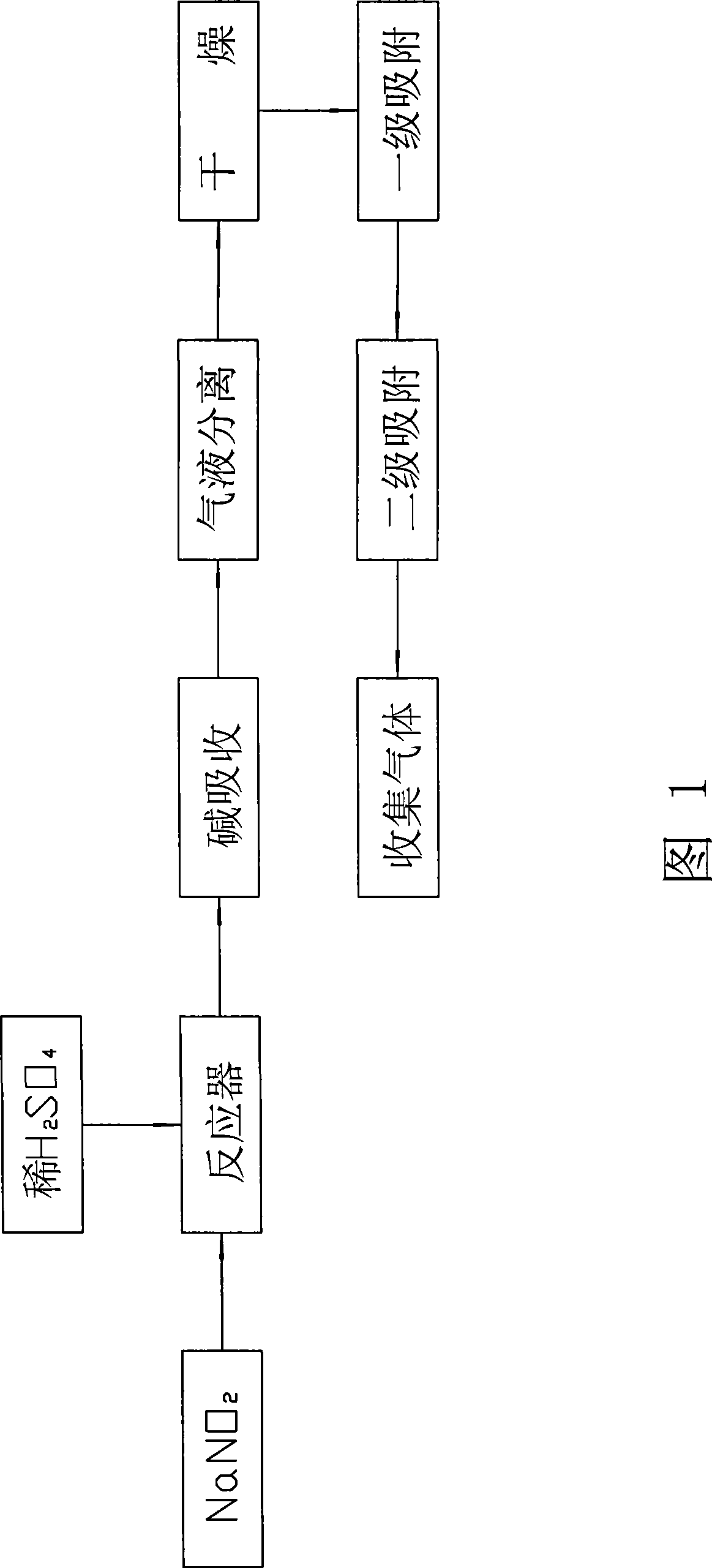

[0014] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

[0015] Same as the prior art, react sodium nitrite and dilute sulfuric acid in the reaction tank, the remaining reaction solution and the generated sodium sulfate and sodium nitrate solution and a small amount of CO 2 , a small part of SO 2 , NO 2 Separation and removal from the bottom of the reactor by alkaline absorption and water washing, most of the NO 2 , N 2 O, water vapor, etc. flow out from the top of the reactor in gaseous form along with NO; water vapor is absorbed and removed in the dryer where the gas flow passes through the presence of anhydrous calcium chloride. What the present invention differs from the prior art is to use polyethylene glycol-methacrylonitrile copolymer adsorbent to absorb NO 2 , N 2 O impurity. That is as shown in Figure 1: It includes decomposing sodium nitrite with dilute sulfuric acid, absorbing lye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com