Inorganic salt/ceramic based composite heat-storing material produced with waste chromic hydroxide and producing method thereof

A technology of ceramic matrix composite and chromium hydroxide, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low sensible heat storage density, low heat storage density, and small heat storage, and improve the acidity. The effect of flue gas corrosion performance, heat storage performance and thermal conductivity improvement, and acceleration of heat absorption and heat release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment.

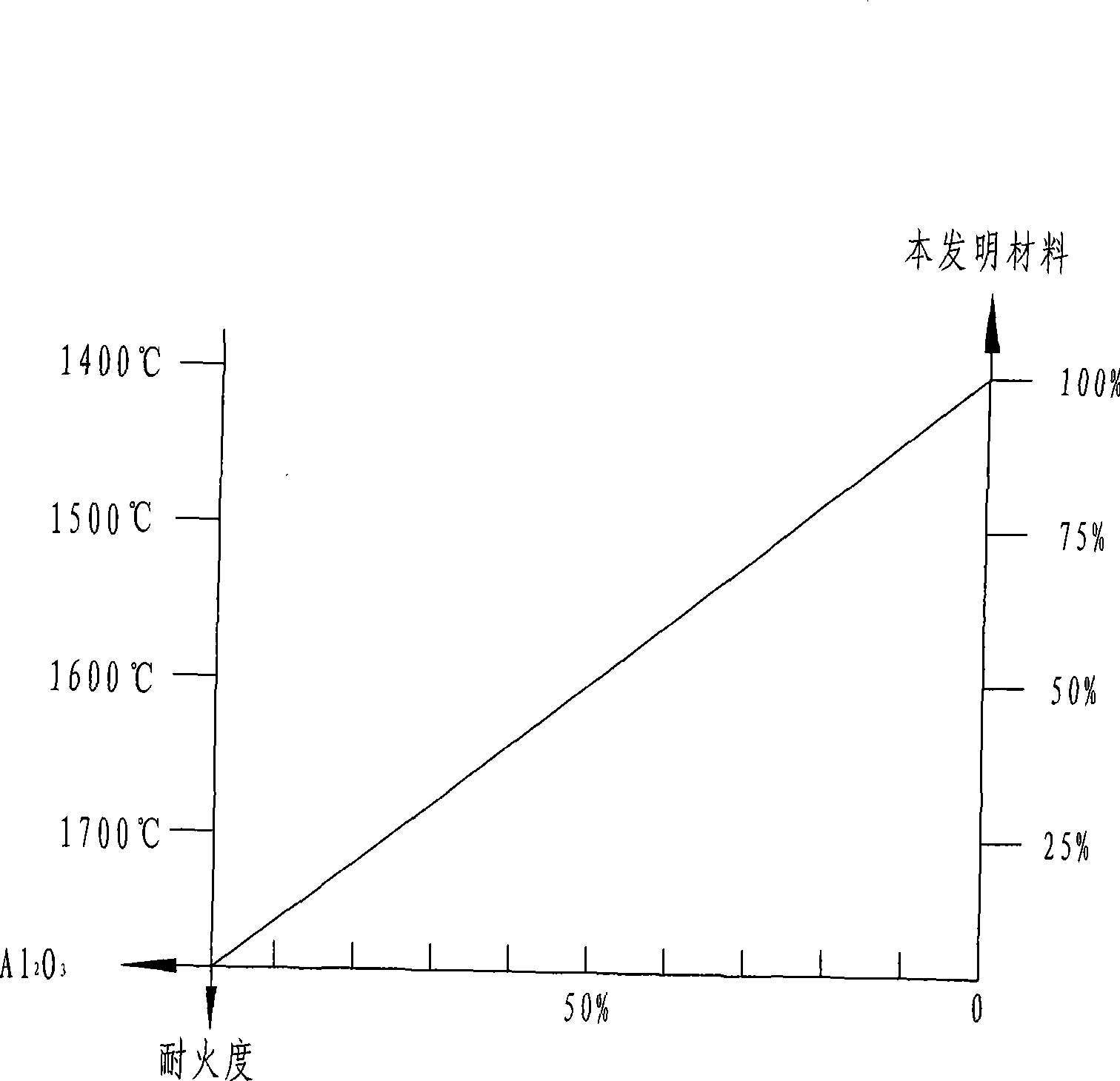

[0009] The present invention uses waste chromium hydroxide to produce inorganic salt / ceramic matrix composite heat storage material, which mainly consists of the following components: waste chromium hydroxide 30Wt%, three stone 38Wt%, zirconium silicate 6Wt%, carbon black 4Wt%, silicon carbide 8Wt%, Magnesium Oxide 14Wt%.

[0010] Batching of the above components → ball mill mixing to 100 μm ~ 5mm → mud dehydration → mud mill extrusion molding → drying → sintering above 1600 ° C → crushing → packaging.

[0011] Inorganic salt / ceramic matrix composite heat storage materials can be made into products such as honeycomb ceramic heat storage bodies, heat storage balls, checker bricks, kiln shed plates and sliders. If nano materials are added, the mechanical performance strength and high temperature strength of the products can be improved. Strengthen 2-3 times, and make the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com