Surface modification method of polymer microporous film

A surface modification and microporous membrane technology, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems affecting the modification efficiency, limited adsorption of hydrophilic polymers, etc., and achieve good safety , stable hydrophilic layer and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

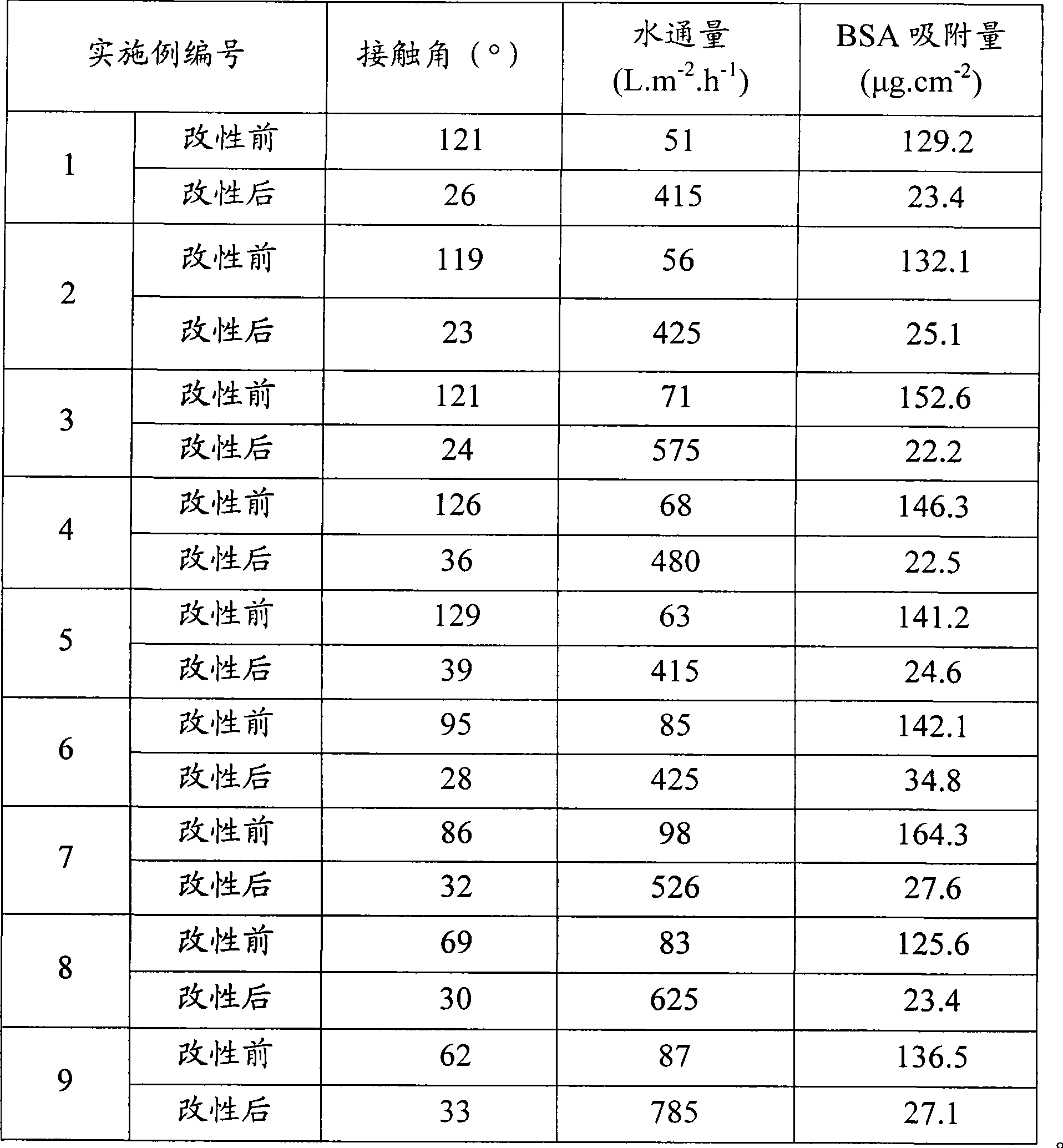

Examples

Embodiment 1

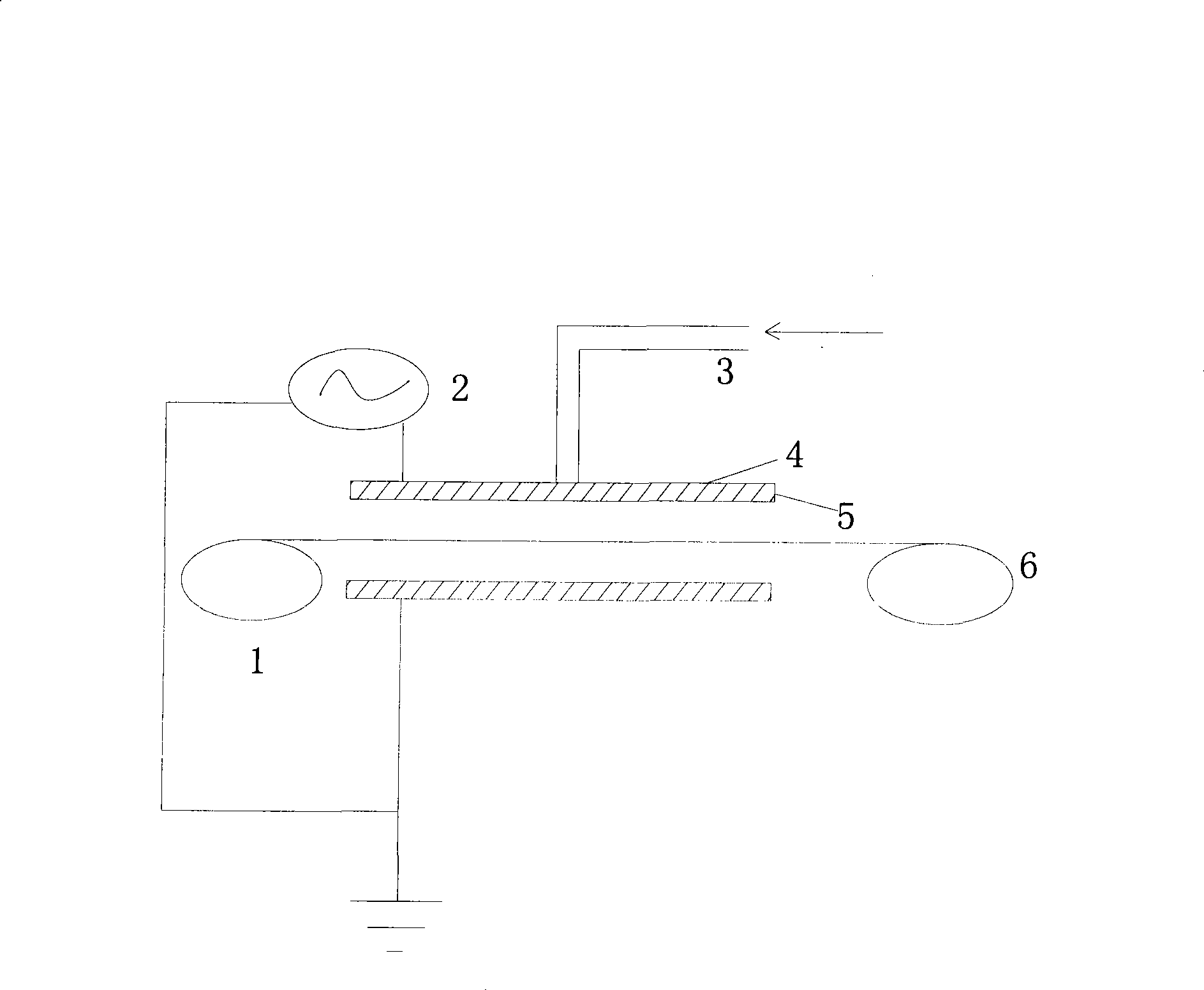

[0033] Example 1: Modification process of polyethylene flat film treated with atmospheric pressure plasma.

[0034] Raw materials: polyethylene flat film (film thickness 25 microns, average pore diameter is 0.4 microns, porosity 20%); The aqueous solution of chitosan (the mass percent concentration of chitosan in solution is 6 %, chitosan weight average molecular weight 8000~10000), wherein the aqueous solution of chitosan also contains chlorohydrins, and the quality of chlorohydrins is 5% of chitosan quality.

[0035] After the polyethylene flat film was washed three times with acetone, it was vacuum-dried at room temperature for 3 hours. Carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polyethylene flat film after above-mentioned treatment then, treatment condition is: the gap between discharge electrodes 4 is 2 millimeters; Mixed gas is argon and oxygen (volume ratio is 99 / 1 ), the air intake speed is 4 liters / min; the plasma discharge po...

Embodiment 2

[0036]Embodiment 2: Atmospheric pressure plasma treatment polyethylene hollow fiber membrane modification process

[0037] Raw material: polyethylene hollow fiber membrane (inner diameter 100 micron, outer diameter 500 micron, average pore diameter is 0.8 micron, porosity 40%), the aqueous solution of polyethylene glycol (polyethylene glycol in the solution) that is used for membrane surface dipping The mass percent concentration is 8%, and the weight average molecular weight is 18000-20000), wherein the polyethylene glycol aqueous solution also contains chlorohydrins, and the mass of chlorohydrins is 3% of the polyethylene glycol mass.

[0038] After washing the polyethylene hollow fiber membrane three times with acetone, it was vacuum-dried at room temperature for 3 hours. Carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polyethylene hollow fiber membrane after the above-mentioned treatment then, treatment condition is: the gap between disc...

Embodiment 3

[0039] Example 3: Modification process of polypropylene flat film treated with atmospheric pressure plasma.

[0040] Raw material: polypropylene flat film (film thickness 200 microns, average pore diameter is 1 micron, porosity 60%), is used for the aqueous solution of the polyvinylpyrrolidone of membrane surface dip-coating (mass percentage concentration of polyvinylpyrrolidone in solution is 12%, the weight average molecular weight of polyvinylpyrrolidone is 15000~18000), wherein the aqueous solution of polyvinylpyrrolidone contains potassium persulfate, and the quality of potassium persulfate is 4% of the quality of polyvinylpyrrolidone.

[0041] After the polypropylene flat film was washed three times with acetone, it was vacuum-dried at room temperature for 3 hours. Then carry out atmospheric pressure dielectric barrier discharge plasma treatment to the polypropylene flat film after above-mentioned treatment, treatment condition is: the gap between discharge electrode 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com