Preparation method of nano nickel copper zinc ferrite powder

A nickel-copper-zinc ferrite, nano-scale technology is applied in the field of preparation of nickel-copper-zinc ferrite powder, which can solve the problems of easy disconnection, weakened magnetic properties, slow development of electromagnetic coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

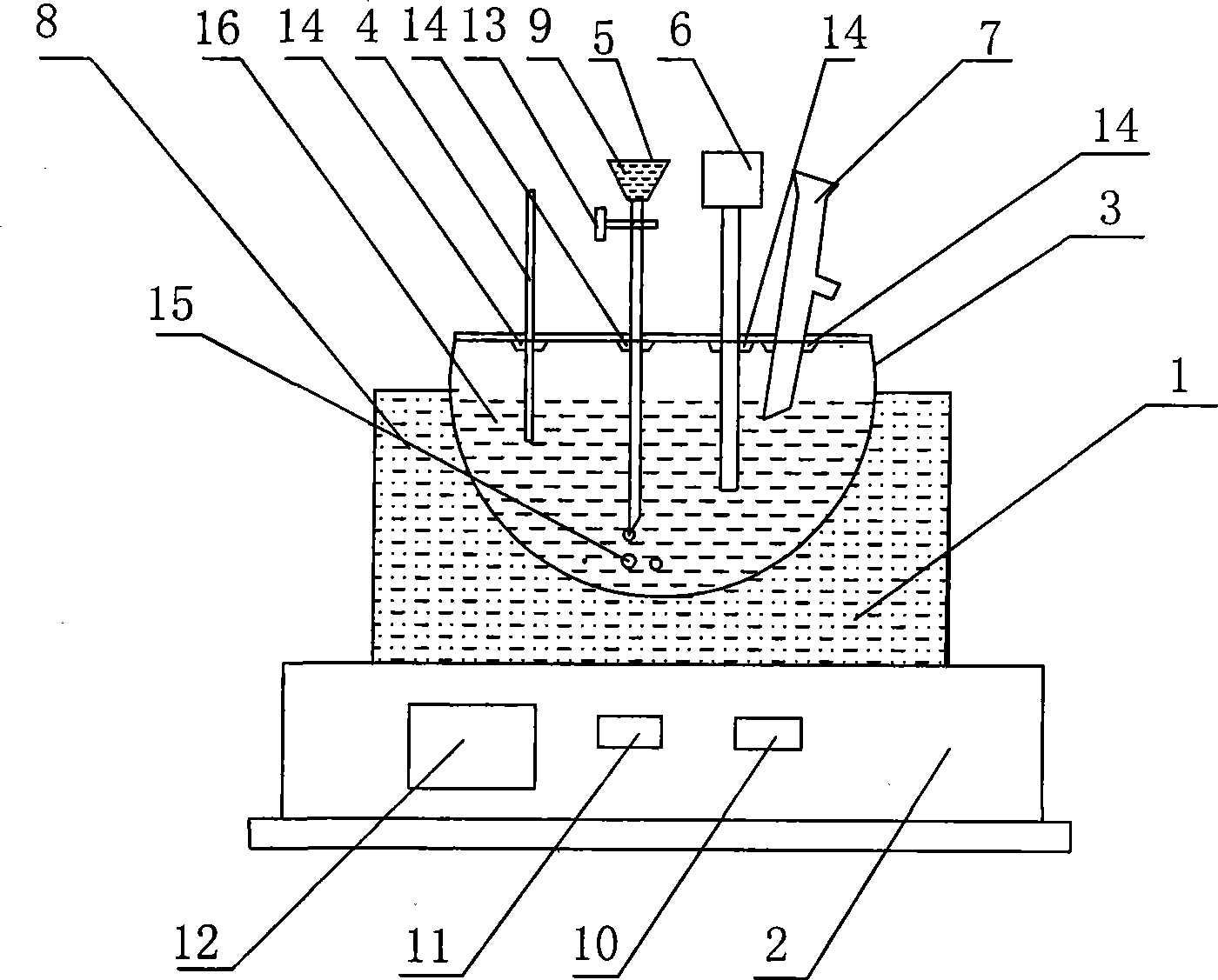

[0106] The present invention will be further described below in conjunction with accompanying drawing:

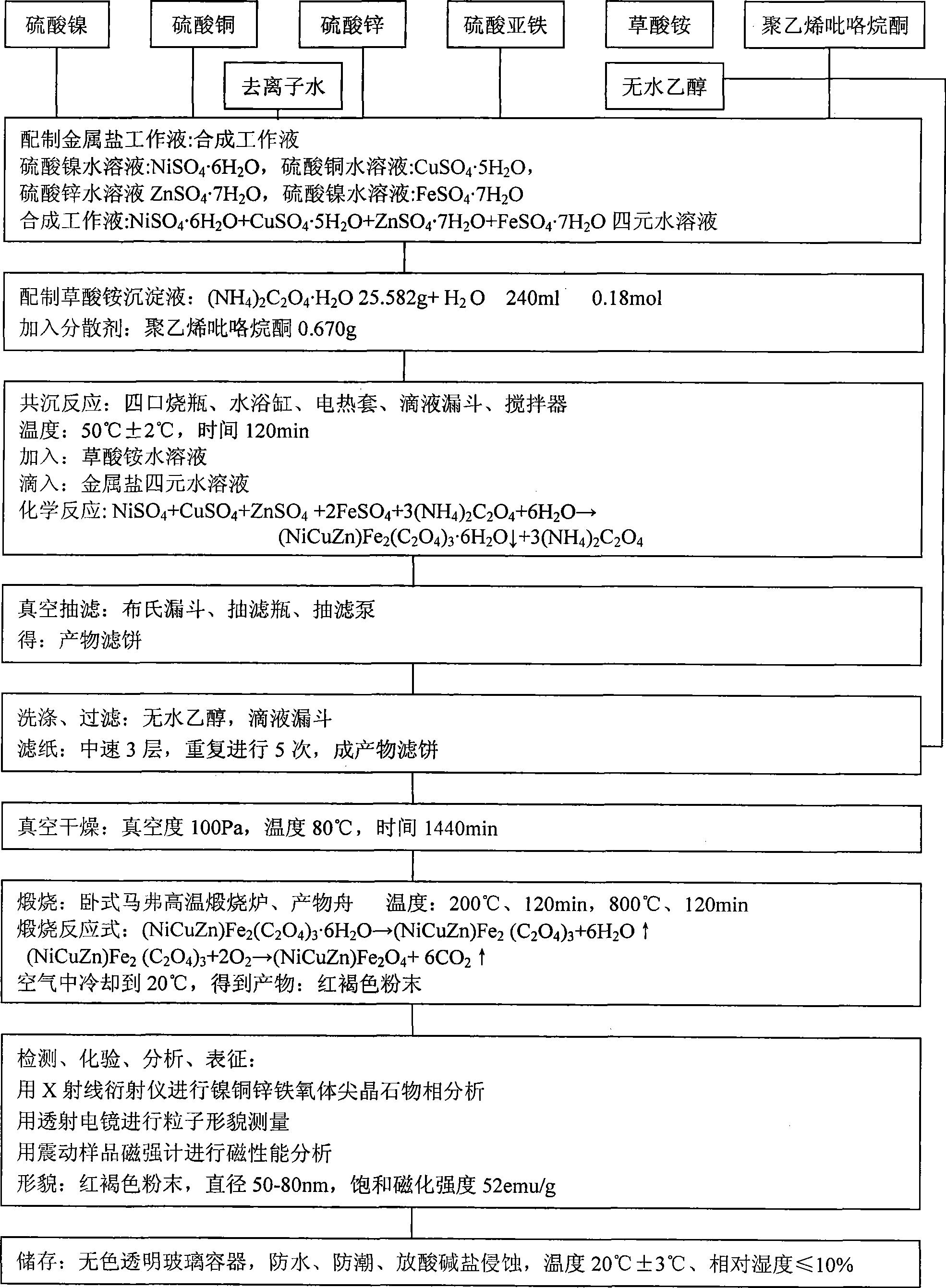

[0107] figure 1 As shown, it is the preparation process flow chart, which must be carried out strictly according to the process steps and operated in sequence.

[0108] The amount of the chemical substance used in the preparation is determined according to the preset range, with gram, milliliter, and minute as the unit of measurement, and when it is produced industrially, the unit of measurement is kilogram, liter, and hour.

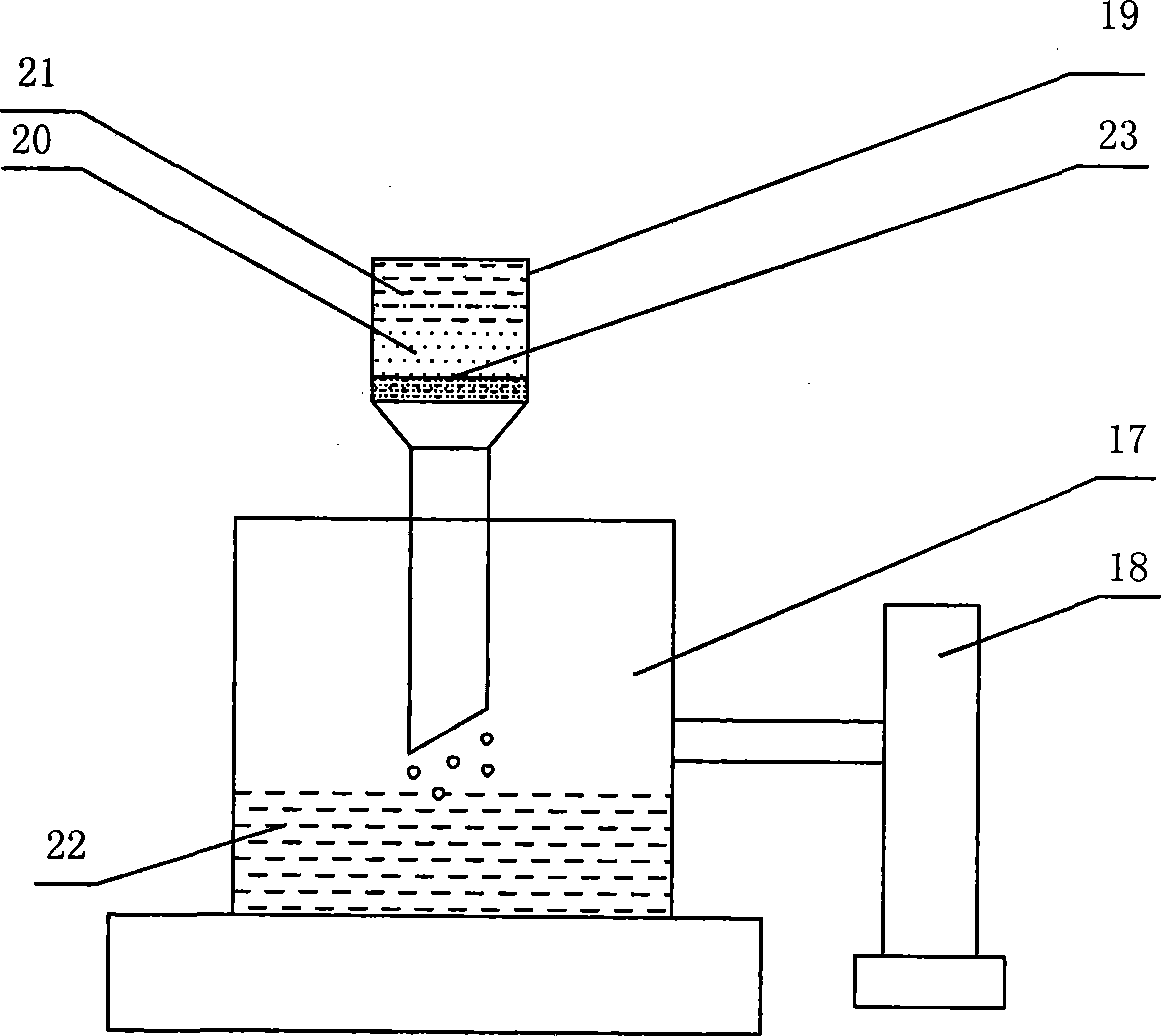

[0109] Four-neck flasks, water baths, dropping funnels, magnetic stirrers, vacuum filtration bottles, Buchner funnels, containers, calciners, product boats, etc. used in preparation should be kept clean and free from contamination to prevent by-products from being generated.

[0110] The preparation of nickel sulfate solution, copper sulfate solution, zinc sulfate solution, ferrous sulfate solution and ammonium oxalate solution should be carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com