Comprehensive processing method for furfural production wastewater

A technology for comprehensive treatment of production wastewater, applied in natural water treatment, heating water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large solvent consumption, by-products, secondary pollution, etc., and achieve stable water quality , large amount of wastewater treatment, strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Preprocessing

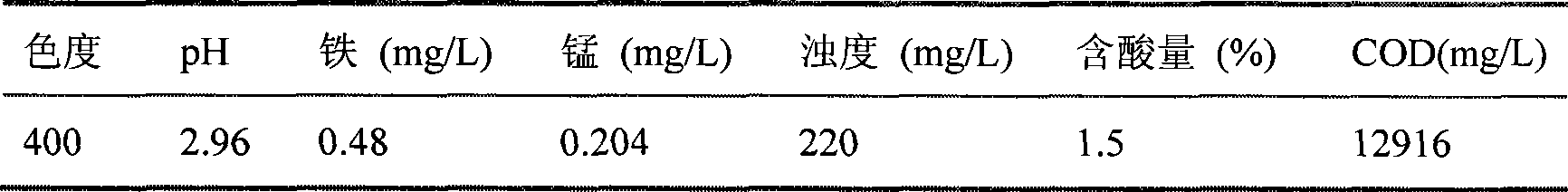

[0030] Add flocculants and activated clay to the raw water, and after flocculation air flotation, sand filtration and activated carbon filtration, the furfural wastewater is light yellow and transparent aqueous solution. The amount of activated carbon used is 100-200mg / L, and the composition of wastewater is shown in Table 2. Pretreatment has almost no effect on acetic acid and COD, but has a great effect on turbidity and color. Use this water as the feed water for the electrodialysis unit.

[0031] Table 2: Water quality composition before and after wastewater pretreatment

[0032]

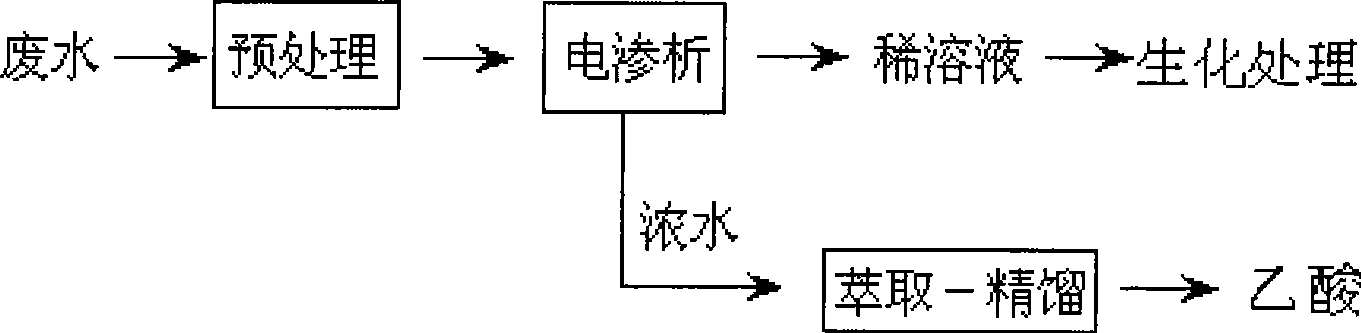

[0033] Step 2: Click Attach figure 1 , 50L of furfural wastewater (acetic acid concentration 1.45%) after pretreatment is used as electrodialysis dense phase and dilute phase, 0.1mol / L Na 2 SO 4 The aqueous solution is used as the polar water, which is driven by the pump to circulate in the electrodialyzer. The flow rate of the concentrated and dilute phases...

Embodiment 2

[0039] Step 1: Same as Step 1 of Example 1.

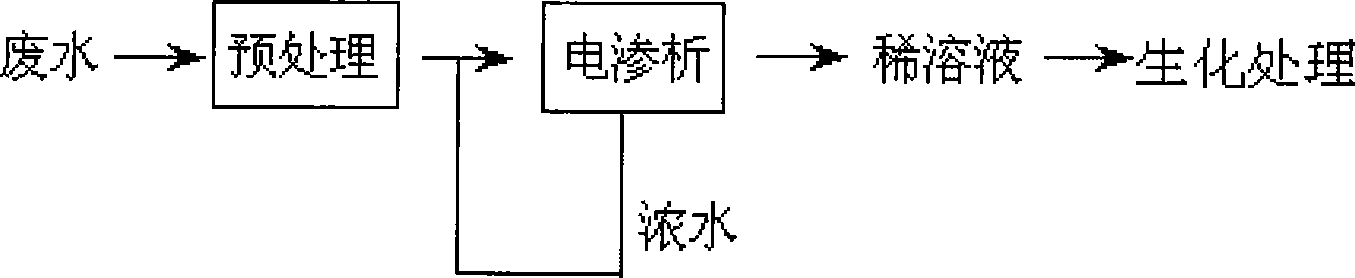

[0040] Step 2: 50L of furfural wastewater (acetic acid concentration 1.45%) after pretreatment is used as electrodialysis dense phase and dilute phase, 0.1mol / L Na 2 SO 4 The aqueous solution is used as the polar water, which is driven by the pump to circulate in the electrodialyzer. The flow rate of the concentrated and dilute phases is kept at 25L / min, the flow rate of the polar water is kept at 10L / h, and the tank pressure is controlled at 60V. dense phase wastewater figure 2 The mode circulates, or reaches a certain concentration for batching. The dilute phase is subjected to circular separation and deacidification, and after treatment, the concentration of acetic acid in the dilute phase is reduced to 0.1-0.3% for biochemical treatment.

[0041] Step 3: Dilute Phase Biochemical Treatment

[0042] Get the dilute phase waste water of appropriate acetic acid concentration 0.1~0.3%, operate by embodiment 1 step 4, waste water...

Embodiment 3

[0044] Step 1: Same as Step 1 of Example 1.

[0045] Step 2: Same as step 2 of Example 1.

[0046] Step 3: Same as Step 3 of Example 1.

[0047]Step 4: Dilute Phase Biochemical Treatment

[0048] Take an appropriate amount of dilute-phase wastewater with an acetic acid concentration of 0.1-0.3%, neutralize it with lime milk, and then enter the anaerobic baffle reactor inoculated with bacteria. At 20-35°C, the hydraulic retention time is 2.5-3.5h, The wastewater after anaerobic biodegradation is then aerobically treated to make the wastewater COD cr It can be reduced to below 100mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com