Composite sustained-release urea of organic materials and method of producing the same

An organic material and slow-release urea technology, applied in the agricultural field, can solve the problems of low production process cost, unsatisfactory nutrient slow-release effect, poor controlled-release performance, etc., to reduce agricultural costs, uniform and smooth product particles, and enhance slow-release effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

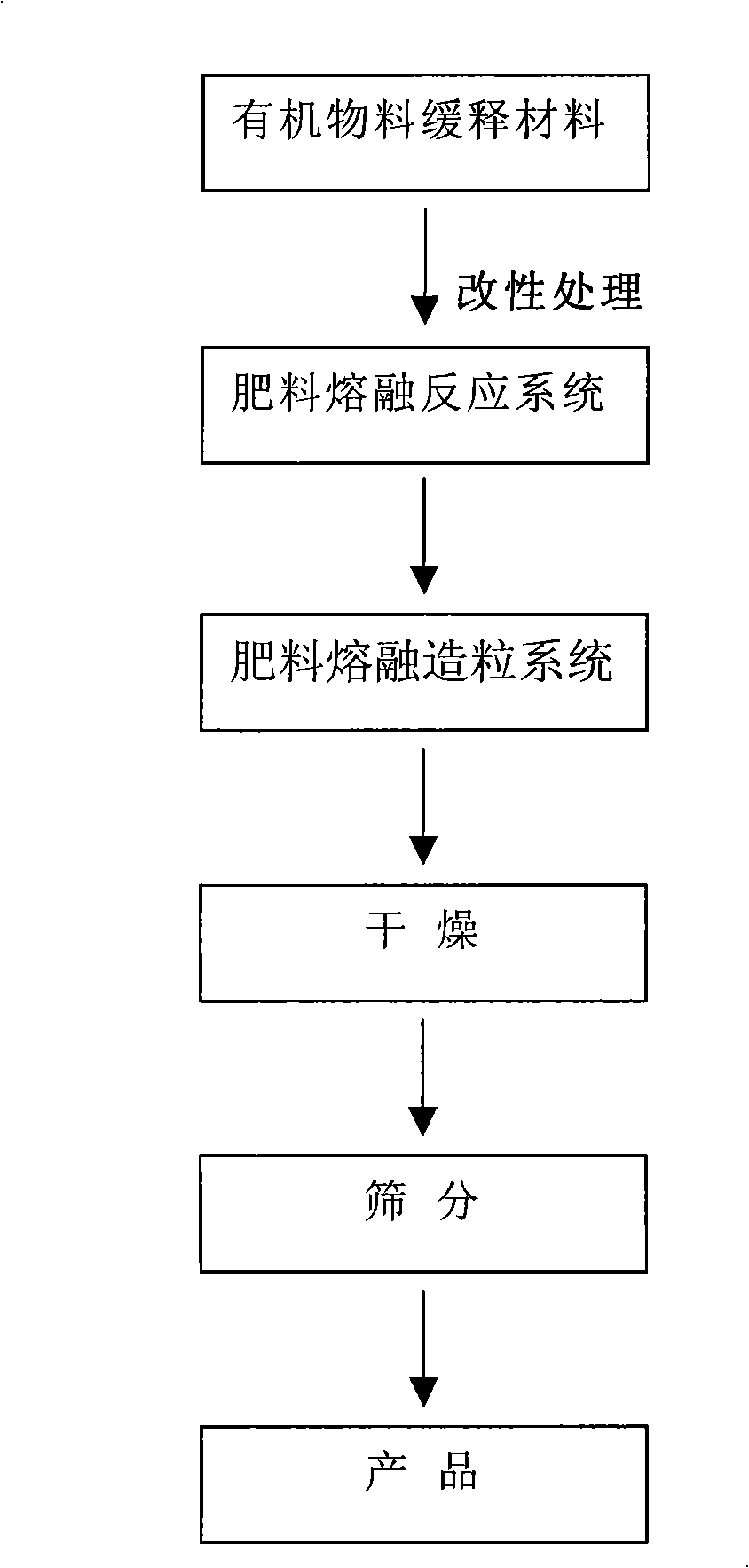

Method used

Image

Examples

Embodiment 1

[0024] The weathered coal material is crushed, sieved (≥80 mesh), and then subjected to fermentation and composting treatment (see "Solid Waste Composting and Organic Compound Fertilizer Production", Li Guoxue, Zhang Fusuo, 2000, Beijing: Chemical Industry Press ), after being decomposed, the organic materials are dried (2~3% water content), crushed (fineness ≥100 mesh), and added into the urine or molten urea before granulation of industrial synthetic urea at a weight ratio of 3:7 (temperature 125°C, mass percentage concentration 96%), stirring and mixing, the heating steam pressure in the urea melting tank is 1.0 MPa. Then it is sent to the high-tower spray granulation equipment for spray granulation. The heat preservation steam pressure of the urine pipeline is 0.25MPa, the material temperature in the granulator is 62°C, and the water content of the material after granulation is 3 to 5%. After granulation, it enters the drying cylinder for drying, which is the finished product....

Embodiment 2

[0026] The organic waste dregs from food factories, wood processing enterprises and lignin wastes from the paper industry are crushed and sieved (≥80 mesh), and then subjected to fermentation composting (method as in Example 1). After the decomposed, the organic materials are dried ( Water content 2~3%), crushed (fineness ≥100 mesh), added to the urine or molten urea before granulation of industrial synthetic urea in a ratio of 2:3 by weight (temperature 125℃, mass percentage concentration 96%) , Stirring and mixing, the heating steam pressure in the urea melting tank is 1.0MPa, and then sent to the high-tower shotcreting equipment for shotcreting. The heat preservation steam pressure of the urine pipeline is 0.25MPa, the material temperature in the granulator is 62°C, and the water content of the material after granulation is 3 to 5%. After granulation, it enters the drying cylinder for drying, which is the finished product. The inlet temperature of the dryer is 150°C, and the ou...

Embodiment 3

[0028] The organic materials such as crop stalks and husks are crushed and sieved (≥80 mesh), and then subjected to fermentation and composting (the method is as in Example 1). After they are decomposed, the organic materials are dried (with water content of 2 to 3%) and crushed (fine (Degree ≥100 mesh), add the urine or molten urea before granulation of industrial synthetic urea (temperature 125℃, mass percentage concentration 96%) in a weight ratio of 1:1, stir and mix, and heat steam in the urea melting tank The pressure is 1.0MPa, and then it is sent to the high tower shotcreting equipment for shotcreting. The heat preservation steam pressure of the urine pipeline is 0.25MPa, the material temperature in the granulator is 62°C, and the water content of the material after granulation is 3 to 5%. After granulation, it enters the drying cylinder for drying, which is the finished product. The inlet temperature of the dryer is 140°C and the outlet temperature is 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com