Polyethylene terephthalate/basalt fiber composite material and preparation method thereof

A polyethylene terephthalate and basalt fiber technology, applied in coatings and other directions, can solve problems such as limited volcanic lava resources, limited development and application prospects, and high-performance fiber composite materials that have not yet been seen, and achieve excellent mechanical properties Performance, dimensional stability, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

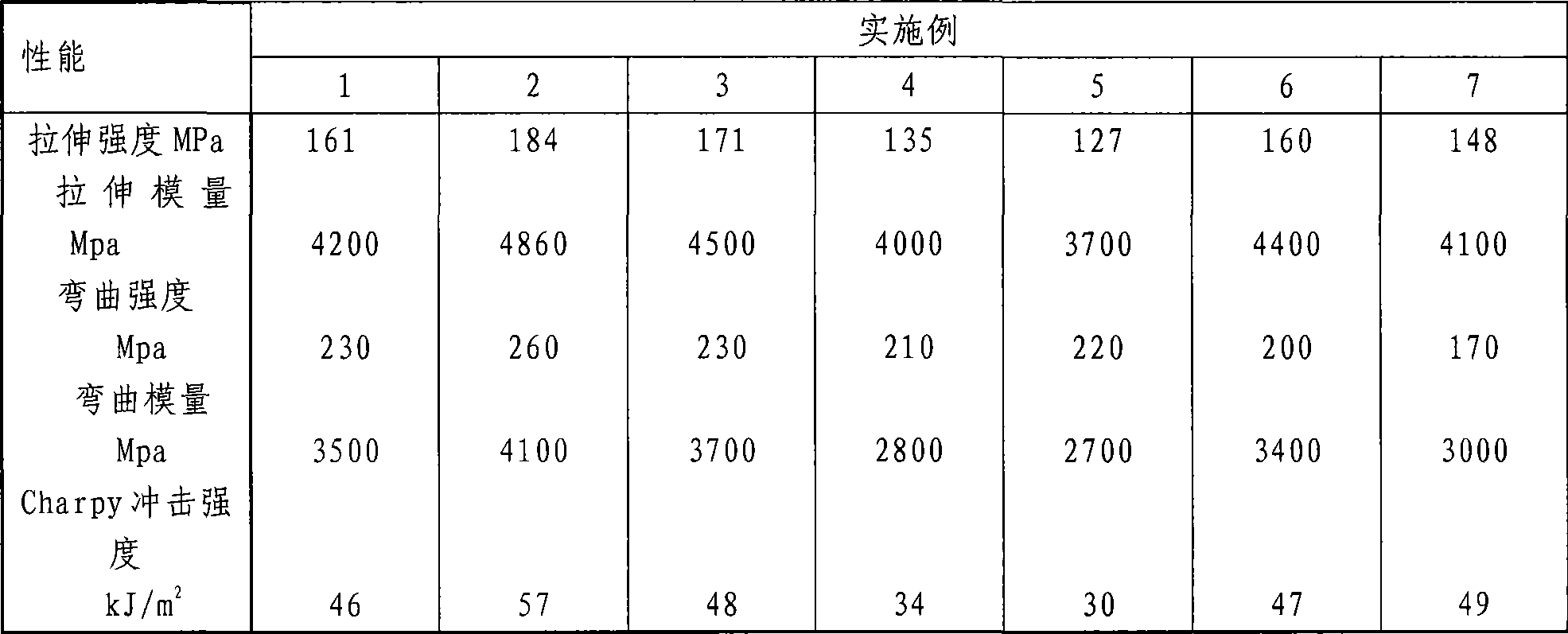

Examples

Embodiment 1

[0028] PET and basalt fibers with a diameter of 3 μm were dried in an oven at 110°C for 4 hours, then 5.00kg of PET, 200g of polyethylene glycol, 400g of TAIC, and 50g of additives were mixed evenly with a mixer, and then added to a 6-zone heating Injection machine, melted and mixed in twin-screw extruder with length-to-length ratio of 32:1, 3.35kg of basalt fiber was added to the vent hole in zone 5, and the heating temperatures in zone 6 were 225±5°C and 265±5°C respectively. 5°C, 270±5°C, 275±5°C, 275±5°C, 275±5°C, the temperature of the machine head is 270±5°C, and the mixed material is cut into pellets. Dry it in an oven at 80°C for 4 hours, and then put it into a nitrogen-protected polyethylene bag and irradiate 70kGy to prepare a composite material.

Embodiment 2-5

[0030] Raw material weight percent composition and processing technology are the same as embodiment 1, but vinyl polyfunctional group monomer becomes trimethylolpropane triacrylate (TMPTA), pentaerythritol triacrylate (PETA) successively in embodiment 2-5 , Phthalate glycol diacrylate (PDDA), tripropylene glycol diacrylate (TPGDA).

Embodiment 6

[0032] PET and basalt fibers with a diameter of 7 μm were dried in an oven at 110° C. for 4 hours, and the processing technology was the same as in Example 1. The composition of raw materials is as follows: PET 5.00kg, basalt fiber 2.5kg, polypropylene glycol 300g, TMPTA 730g, processing aid 170g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com