Preparation method of ZnO nano crystal whisker reinforced silicon-based lead zirconate titanate piezoelectric composite thick film

A technology of silicon-based zirconium titanate and nano whiskers, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problems of large loss of piezoelectric performance, failure, and large surface roughness, and achieve surface The effect of smooth and crack-free, wide application potential and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

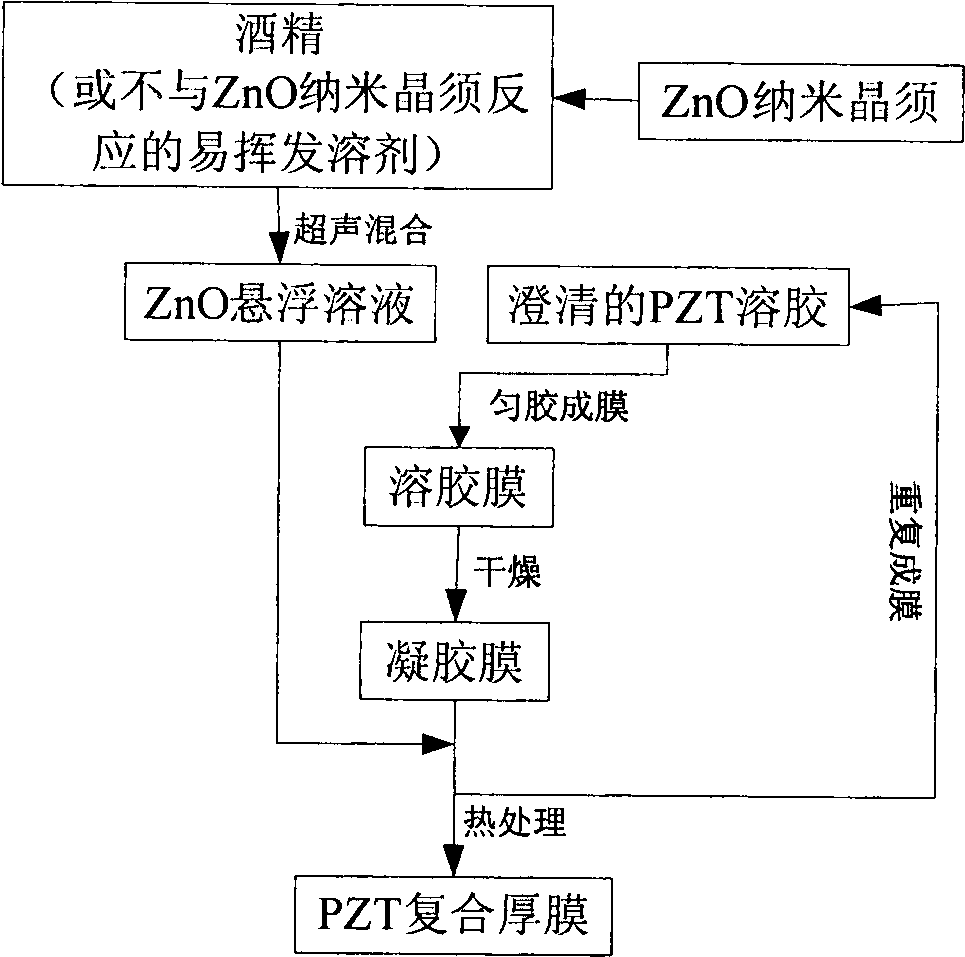

Method used

Image

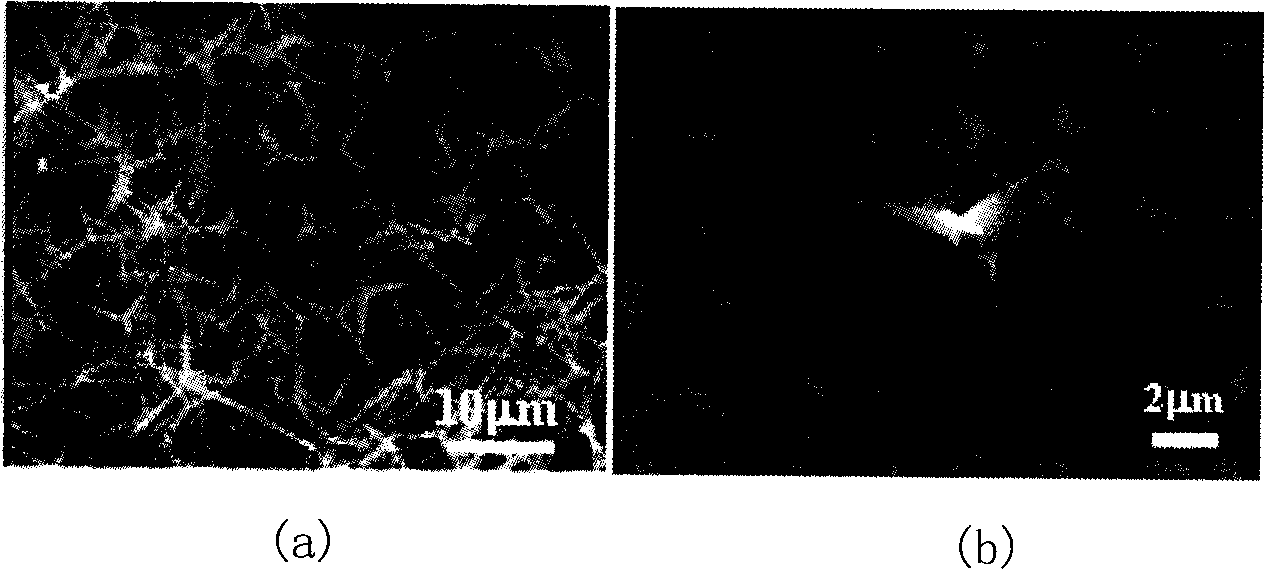

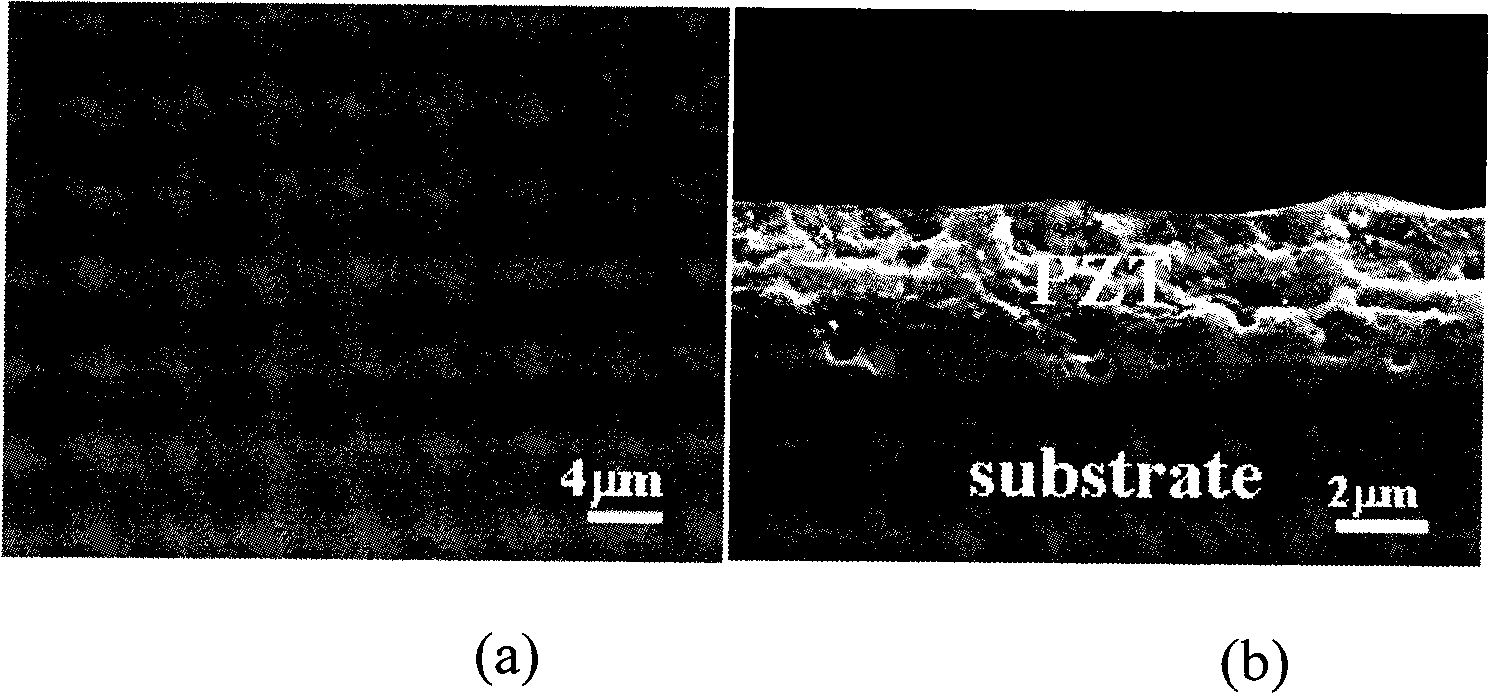

Examples

Embodiment 1

[0027] 1) The raw materials used in the experiment are analytically pure lead acetate trihydrate, zirconium nitrate and tetrabutyl titanate, ethylene glycol monomethyl ether and glacial acetic acid are used as solvent, and acetylacetone is used as catalyst; according to the chemical formula Pb(Zr 0.52 Ti 0.48 )O 3 The molar ratio of raw materials is weighed, and the final PZT sol concentration is controlled at 0.4Mol / l;

[0028] 2) First, dissolve zirconium nitrate in ethylene glycol monomethyl ether to form a solution with a concentration of 0.25Mol / l, stir until transparent and clear, then add tetrabutyl titanate and acetylacetone, reflux and stir until clear. Among them, acetylacetone is used as a stabilizer, and its volume ratio to tetrabutyl titanate is 1:1.6;

[0029] 3) Dissolve analytically pure lead acetate trihydrate in acetic acid, the concentration of the acetic acid solution of lead acetate trihydrate is 2Mol / l, heat between 100°C and 117°C for 20min, distill to...

Embodiment 2

[0036] 1) The raw materials used in the experiment are analytically pure lead acetate trihydrate, zirconium nitrate and tetrabutyl titanate, ethylene glycol monomethyl ether and glacial acetic acid are used as solvent, and acetylacetone is used as catalyst; according to the chemical formula Pb(Zr 0.52 Ti 0.48 )O 3 The molar ratio of raw materials is weighed, and the final PZT sol concentration is controlled at 0.4Mol / l;

[0037] 2) First, dissolve zirconium nitrate in ethylene glycol monomethyl ether to form a solution with a concentration of 0.25Mol / l, stir until transparent and clear, then add tetrabutyl titanate and acetylacetone, reflux and stir until clear. Among them, acetylacetone is used as a stabilizer, and its volume ratio to tetrabutyl titanate is 1:1.6;

[0038] 3) Dissolve analytically pure lead acetate trihydrate in acetic acid, the concentration of the acetic acid solution of lead acetate trihydrate is 2Mol / l, heat between 100°C and 117°C for 20min, distill to...

Embodiment 3

[0045] 1) The raw materials used in the experiment are analytically pure lead acetate trihydrate, zirconium nitrate and tetrabutyl titanate, ethylene glycol monomethyl ether and glacial acetic acid are used as solvent, and acetylacetone is used as catalyst; according to the chemical formula Pb(Zr 0.52 Ti 0.48 )O 3 The molar ratio of raw materials is weighed, and the final PZT sol concentration is controlled at 0.4Mol / l;

[0046] 2) First, dissolve zirconium nitrate in ethylene glycol monomethyl ether to form a solution with a concentration of 0.25Mol / l, stir until transparent and clear, then add tetrabutyl titanate and acetylacetone, reflux and stir until clear. Among them, acetylacetone is used as a stabilizer, and its volume ratio to tetrabutyl titanate is 1:1.6;

[0047] 3) Dissolve analytically pure lead acetate trihydrate in acetic acid, the concentration of the acetic acid solution of lead acetate trihydrate is 2Mol / l, heat between 100°C and 117°C for 20min, distill to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com