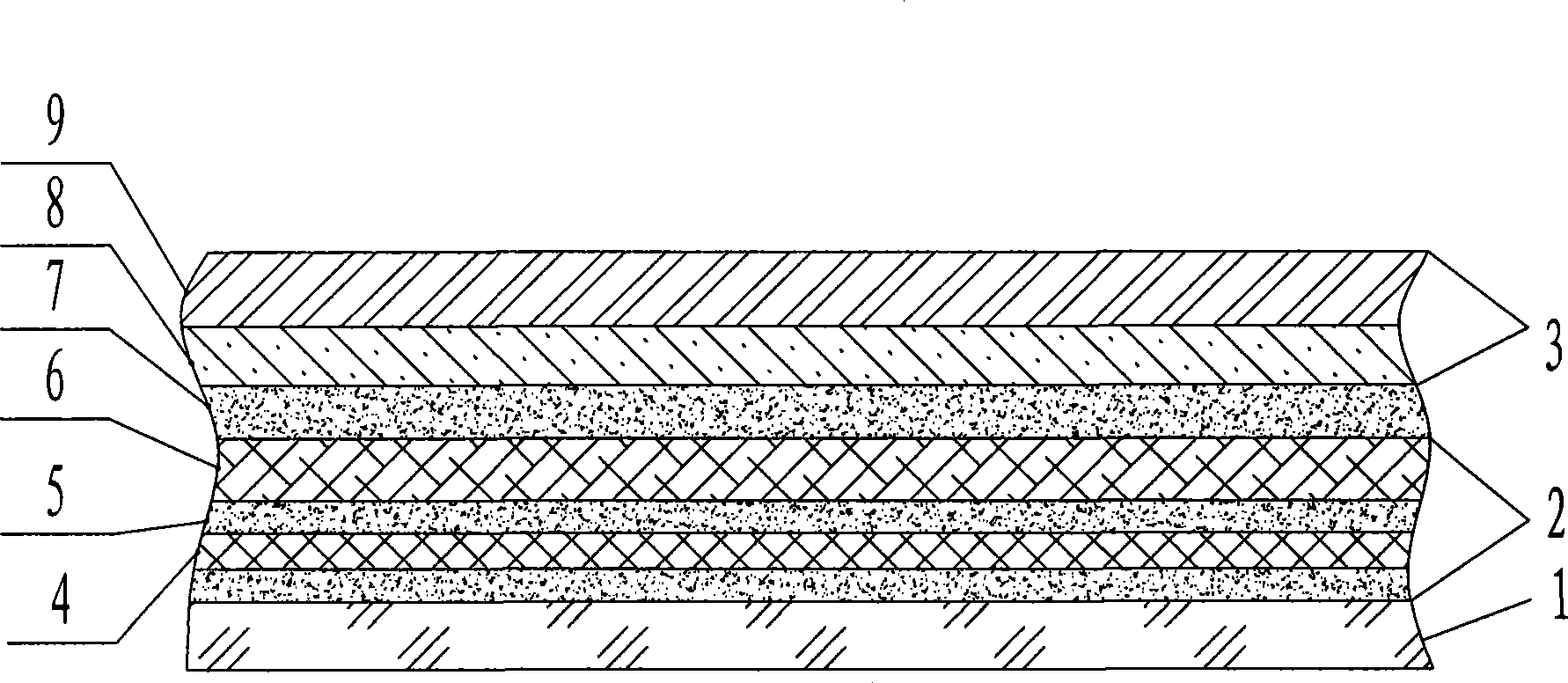

Quasi-solid dye sensitized flexible solar cell battery and its preparation method

A solar cell, dye sensitization technology, applied in the field of flexible solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

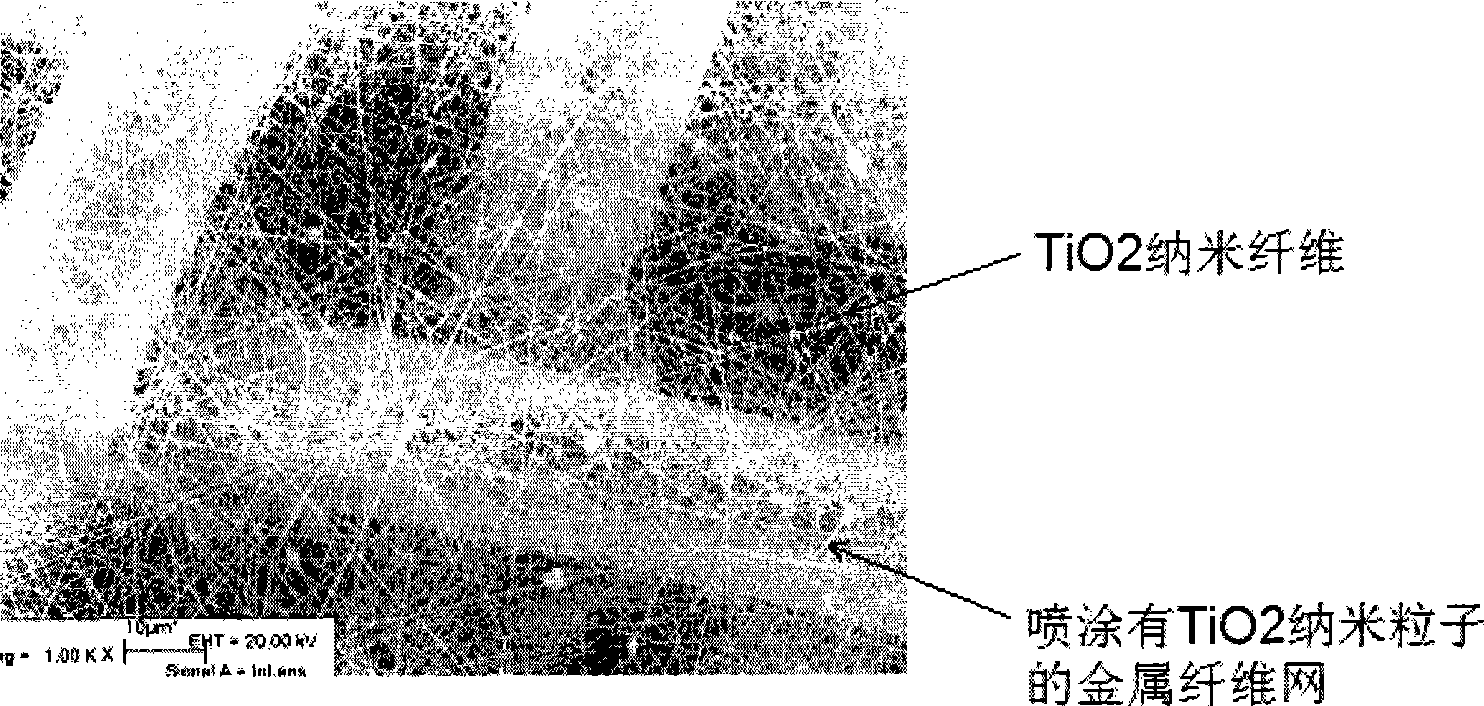

[0024] (1) Clean the prepared 500-mesh stainless steel wire mesh with acetone, burn it at 450°C for 15 minutes, and cool it naturally at room temperature; place the burned stainless steel wire mesh in 0.01M titanium tetrabutyl ester / 0.02M Ultrasonic immersion in the ethanol solution of acetylacetone for 30s, take it out and dry it, then burn it at 450°C for 15 minutes, and cool it naturally, repeat the dipping and burning three times.

[0025] (2) Spray TiO2 2 Preparation of emulsion: weigh 3g TiO 2 (Degussa P25) into an agate mortar, add 1.0mL distilled water (containing 0.1mL acetylacetone), then add 4mL distilled water while grinding, add 2 drops of OP emulsifier (Triton X-100) after grinding for 30min, and continue grinding 10min, add 0.7mL of 1wt% magnesium acetate solution (258.3mg of anhydrous magnesium oxide dissolved in 100mL of glacial acetic acid and 150mL of distilled water), then add 4.3mL of distilled water, grind the TiO 2 The emulsion was transferred to a clo...

Embodiment 2

[0035] (1) Clean the prepared 500-mesh stainless steel wire mesh with acetone, burn it at 450°C for 15 minutes, and cool it naturally at room temperature; place the burned stainless steel wire mesh on 0.01M titanium n-propoxide (Ti-nP) / 0.02M acetylacetone ethanol solution for 30s, take it out and dry it, then burn it at 450°C for 15min, cool it naturally, repeat dipping and burning three times.

[0036] (2) (3) Same as Example 1

[0037] (4) Electrospun TiO 2 Preparation of fiber solution: use polyvinylpyrrolidone (PVP, mass average molecular weight 1,300,000) as the electrospinning carrier, first prepare a 6.5%wt PVP / ethanol solution, then take 1gPVP / ethanol solution and add 0.48g glacial acetic acid, 0.24g n-propanol Titanium (Ti-nP), magnetically stirred for 10 min and set aside.

[0038] (5)~(8) Same as Example 1.

[0039] Test results: N719 dye / ethanol solution, battery open circuit voltage 0.69V, short circuit current density 4.1mA / cm 2 , fill factor 0.68, photoelec...

Embodiment 3

[0042] (1) Clean the prepared 500-mesh stainless steel wire mesh with acetone, burn it at 450°C for 15 minutes, and cool it naturally at room temperature; place the burned stainless steel wire mesh on 0.01M titanium n-propoxide (Ti-nP) / 0.02M acetylacetone ethanol solution for 60 seconds, take it out and dry it, then burn it at 450°C for 15 minutes, cool it naturally, repeat the dipping and burning three times.

[0043] (2) (3) Same as Example 1.

[0044] (4) Electrospun TiO 2 Preparation of fiber solution: use polyvinyl acetate (PVAc, mass average molecular weight 500,000) as the electrospinning carrier, first prepare 12%wt PVAc / DMF solution, then take 1g solution and add 0.066g glacial acetic acid, 0.16g titanium n-propoxide (Ti-nP), magnetically stirred for 10 min and set aside.

[0045] (5) Same as Example 1.

[0046] (6) Immerse the stainless steel mesh electrode obtained in step (5) in the DMF solution for 1-3 seconds, take it out and immediately dry it with a hair dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current density | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com