Release oxygen type porous inorganic/organic composite stent material

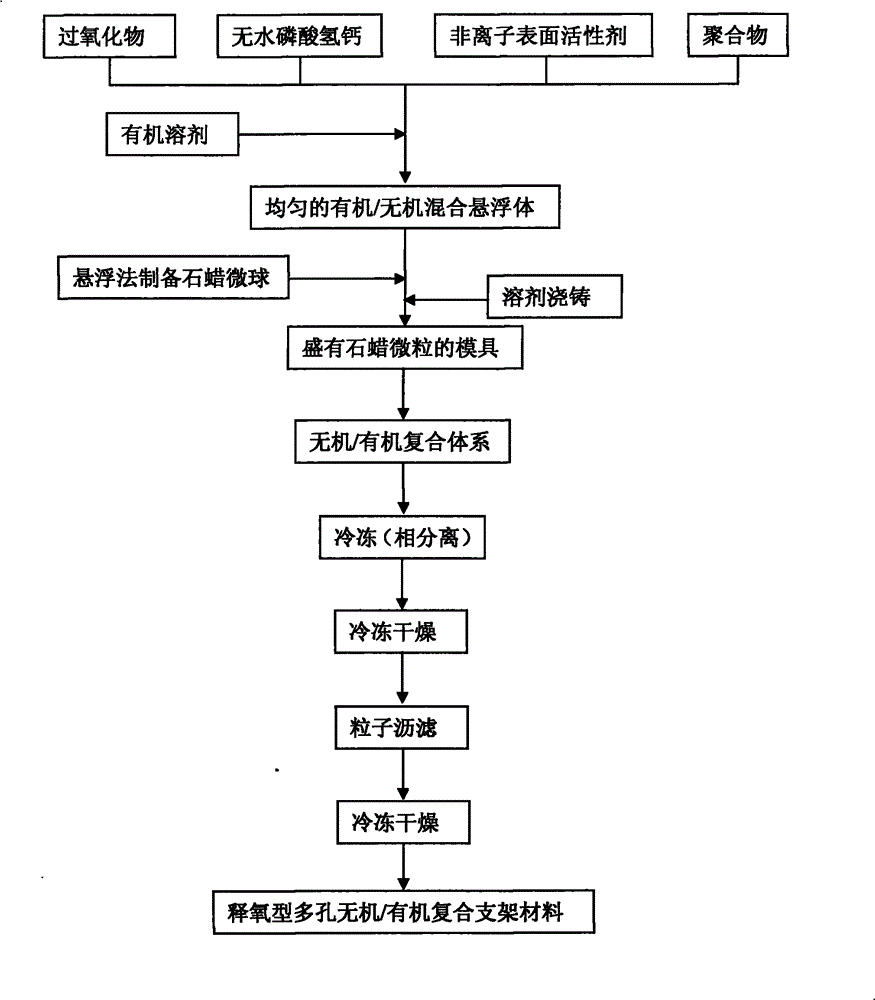

A technology of composite scaffolds and scaffold materials, which is applied in the fields of medical science, microcapsule preparation, microsphere preparation, etc., can solve the problems of poor connectivity between pores and difficult to control pore size, and achieves promotion of adhesion, improvement of mechanical properties, and enhancement of biological activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

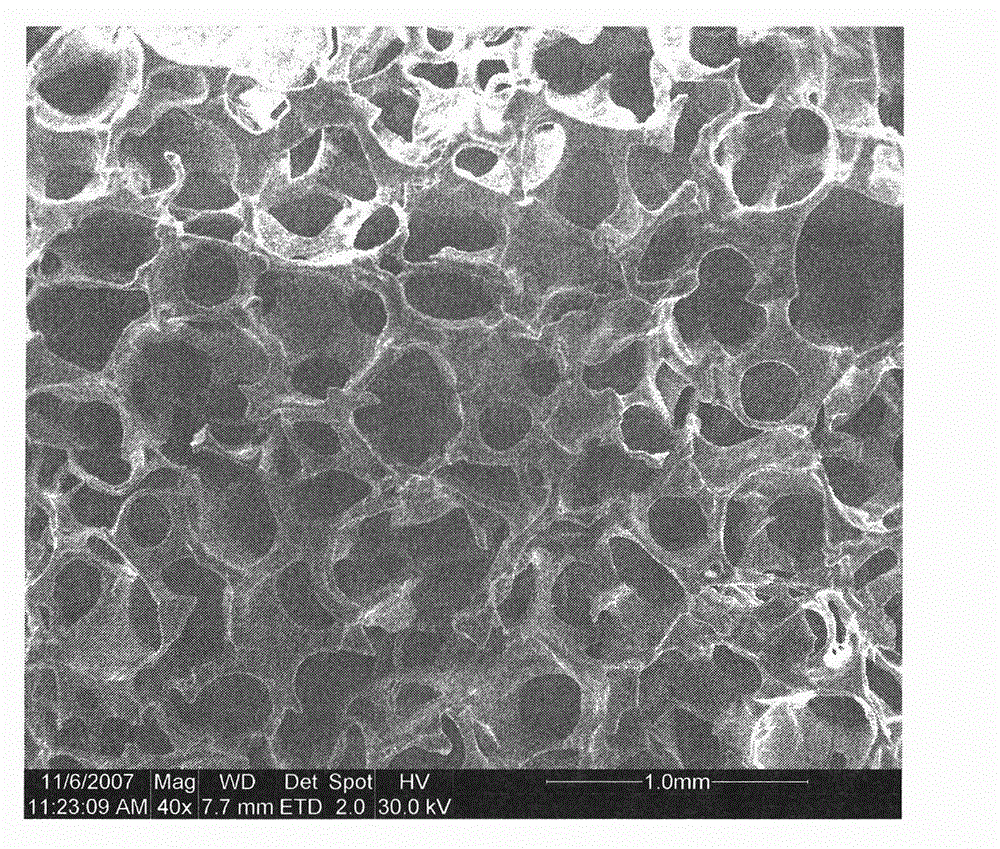

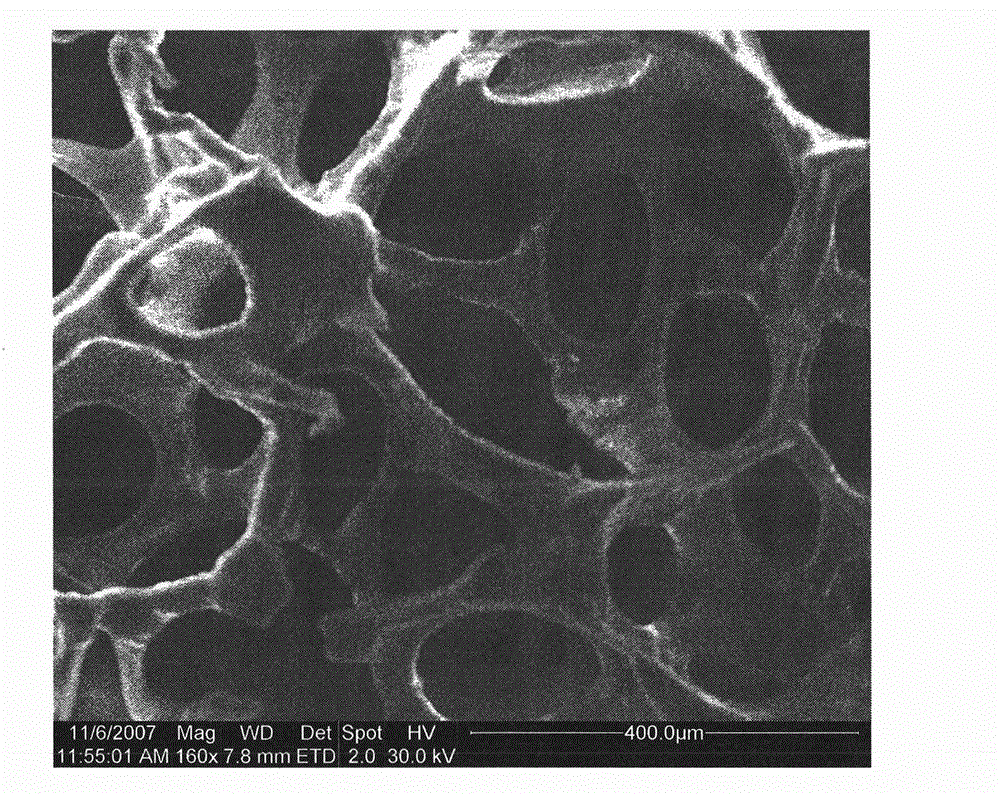

[0038] Paraffin spherical particles were prepared by suspension method. Weigh 10g of block paraffin wax with a melting point of 55°C and 100mL of polyvinyl alcohol aqueous solution with a concentration of 5mg / mL. After the temperature of the alcohol solution is stable, pour the polyvinyl alcohol solution into a beaker filled with liquid paraffin, and stir at a high speed to disperse the paraffin into numerous small paraffin droplets. Then quickly pour 200mL of ice water. Accelerate the solidification of small paraffin droplets to form paraffin microspheres. Rinse the paraffin particles with distilled water 4 to 5 times to remove impurities. Classify the obtained paraffin particles through a national standard sieve to obtain spherical particles of 100-500 μm, and then dry them in a vacuum drying oven.

[0039] Weigh 2g of Pluronic F127 and add it into 100ml of 1,4-dioxane, stir at 25°C to dissolve it completely. This solution contains 0.3g CaO 2 and 0.85g CaHPO 4 Particle...

Embodiment 2

[0041] Paraffin spherical particles were prepared by suspension method. Weigh 10g of block paraffin wax with a melting point of 55°C, measure 150mL of polyvinyl alcohol aqueous solution with a concentration of 5mg / mL, put the above two items in an oven set at 80°C, and keep for 1h until the paraffin wax is completely melted, and the polyethylene After the temperature of the alcohol solution is stable, pour the polyvinyl alcohol solution into a beaker filled with liquid paraffin, and stir at a high speed to disperse the paraffin into numerous small paraffin droplets. Then quickly pour 200mL of ice water. Accelerate the solidification of small paraffin droplets to form paraffin microspheres. Rinse the paraffin particles with distilled water 4 to 5 times to remove impurities. Classify the obtained paraffin particles through a national standard sieve to obtain spherical particles of 100-500 μm, and then dry them in a vacuum drying oven.

[0042] Weigh 3g of Pluronic F127 into 1...

Embodiment 3

[0044] Paraffin spherical particles were prepared by suspension method. Weigh 10g of block paraffin wax with a melting point of 55°C, measure 200mL of polyvinyl alcohol aqueous solution with a concentration of 5mg / mL, put the above two items into an oven with a temperature set at 80°C, and keep for 1.5h until the paraffin wax is completely melted. After the temperature of the vinyl alcohol solution is stable, pour the polyvinyl alcohol solution into a beaker filled with liquid paraffin, and stir at a high speed to disperse the paraffin into countless small paraffin droplets. Then quickly pour 250mL of ice water. Accelerate the solidification of small paraffin droplets to form paraffin microspheres. Rinse the paraffin particles with distilled water 4 to 5 times to remove impurities. Classify the obtained paraffin particles through a national standard sieve to obtain spherical particles of 100-500 μm, and then dry them in a vacuum drying oven.

[0045] Weigh 4g of Pluronic F1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com