Mixed-flow discharge gas treatment method and treatment method

An exhaust gas treatment device and technology for exhaust gas treatment, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as too many components, complex desulfurization tower structure, and complex equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A 220T / h coal-fired power boiler uses high-sulfur coal with a sulfur content of 4.0%, and its flue gas flow rate is 250,000m 3 / h, flue gas containing sulfur dioxide 11,000mg / Nm 3 , containing dust 100mg / Nm 3 , the content of other components, such as sulfur trioxide, nitrogen oxide and hydrogen chloride or hydrogen fluoride, could not be determined, and the flue gas temperature was 125°C.

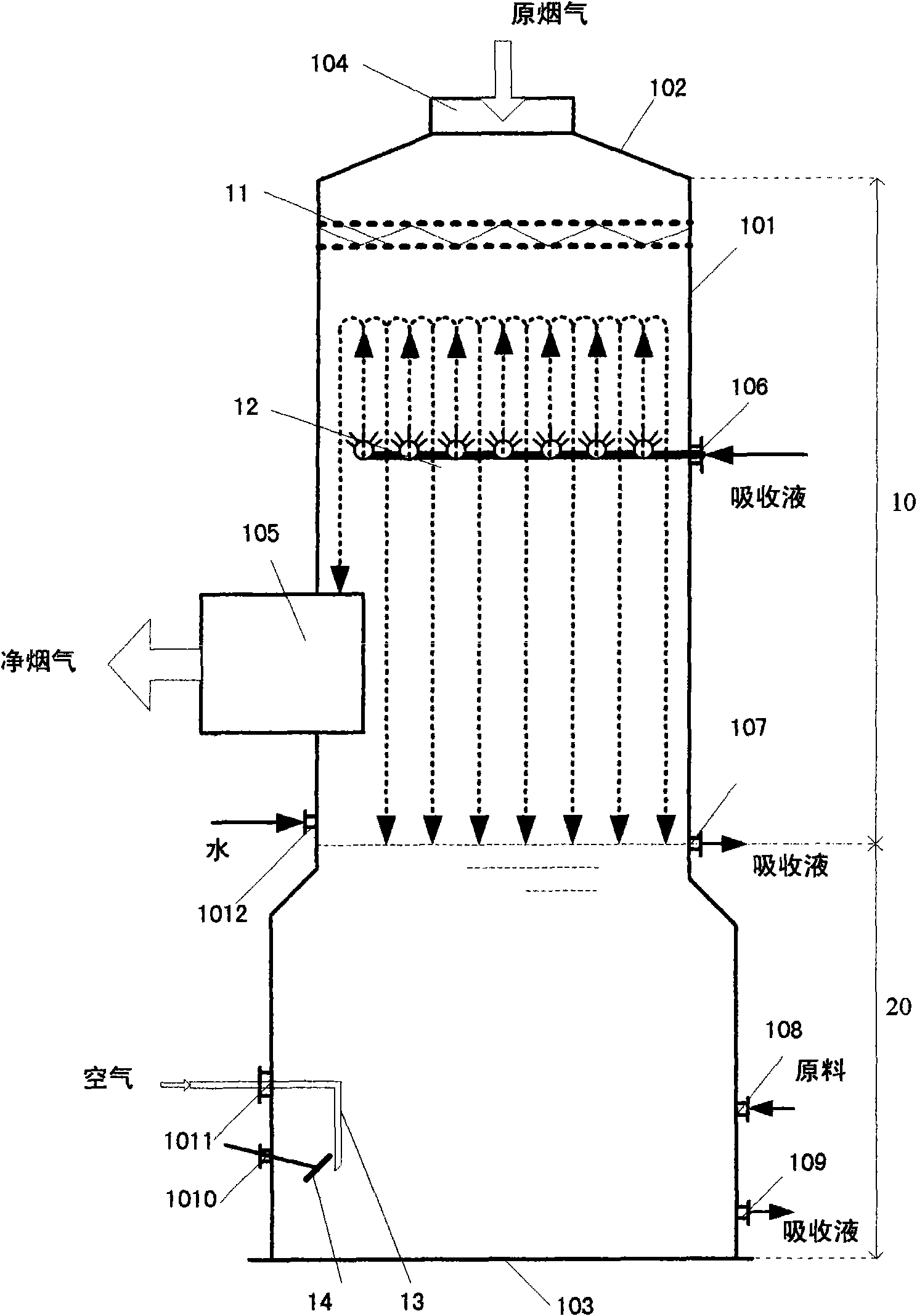

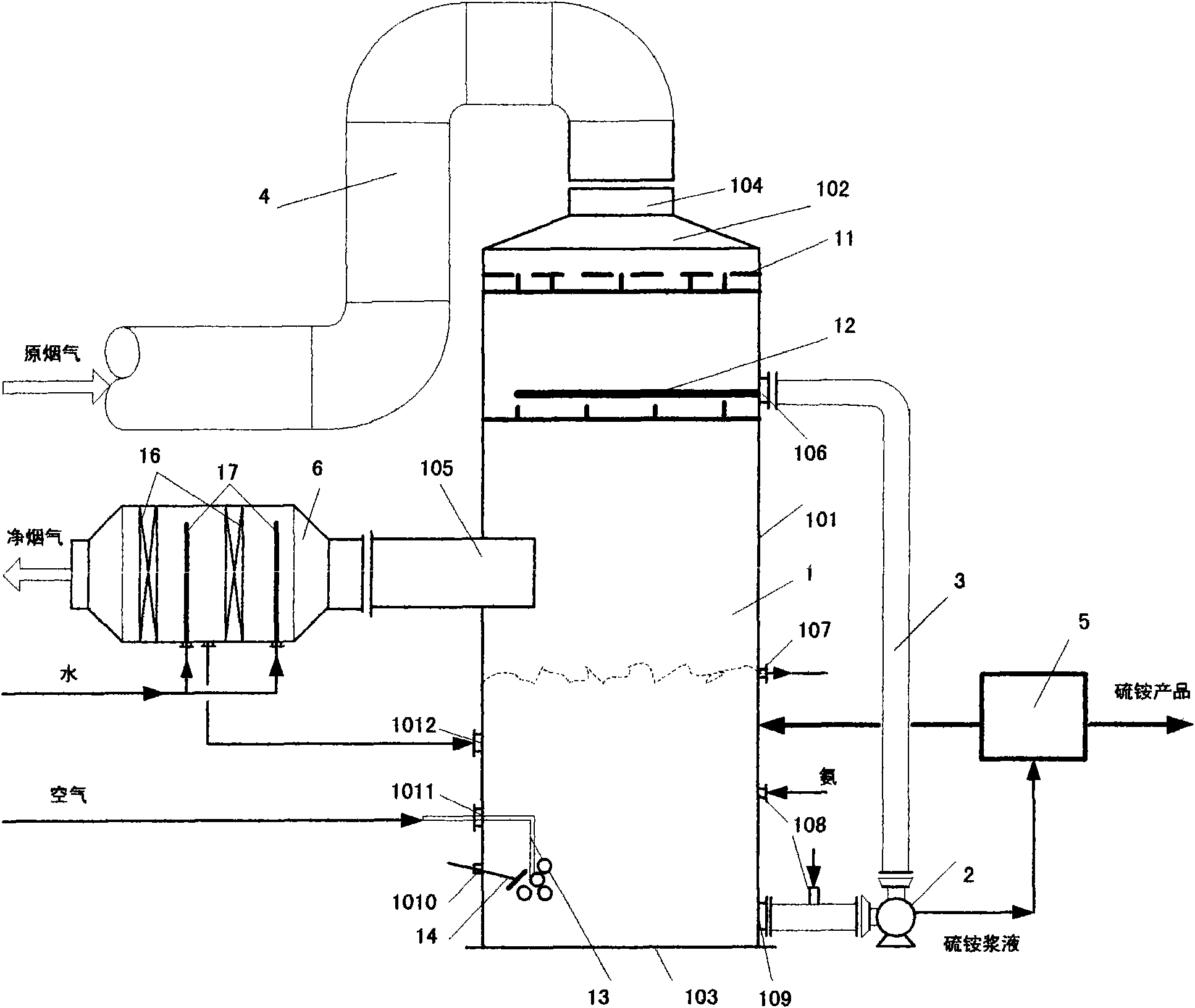

[0049] With the desulfurization method of the present invention, the original flue gas enters the desulfurization tower body from the flue gas inlet 104 at the top of the desulfurization tower 1, first enters the flue gas equalization area 10, and passes through the flue gas distributor 11 to make the flue gas uniform along the entire cross section of the desulfurization tower. flow, and enter the gas-liquid mixed flow area 20 downwards; the flue gas contacts with the absorption liquid droplets containing ammonia sprayed upward from the nozzle of the absorption liquid sprayer 12 at...

Embodiment 2

[0054] A 220T / h coal-fired power boiler uses high-sulfur coal with a sulfur content of 0.5%, and its flue gas flow rate is 250,000m 3 / h, flue gas containing sulfur dioxide 1300mg / Nm 3 , containing smoke dust 50mg / Nm 3 , the content of other components, such as sulfur trioxide, nitrogen oxide and hydrogen chloride or hydrogen fluoride, could not be determined, and the flue gas temperature was 145°C.

[0055] Adopt the method of the present invention, be identical with embodiment 1.

[0056] The raw material ammonia is ammonia water with an ammonia content of 15.0%, and the addition amount is 1100kg / h, and the pH value of the absorption liquid is maintained at 5.3. The ammonia water is continuously added to the absorption liquid, and the addition position is on the absorption liquid circulation line 3, specifically The ammonia provided on the circulation pipe 3 between the absorption liquid circulation outlet 109 of the absorption liquid storage tank 50 and the inlet of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com