Method for synthesizing alkylphenol-polyethenoxy ether terpolymer surfactant

A technology of alkylphenol polyoxyethylene ether and surfactant, which is applied in the field of synthesis of alkylphenol polyoxyethylene ether trimerized surfactant, can solve the problems of complicated process, long reaction time and large equipment investment, etc. Achieve the effect of simple process, easy operation and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

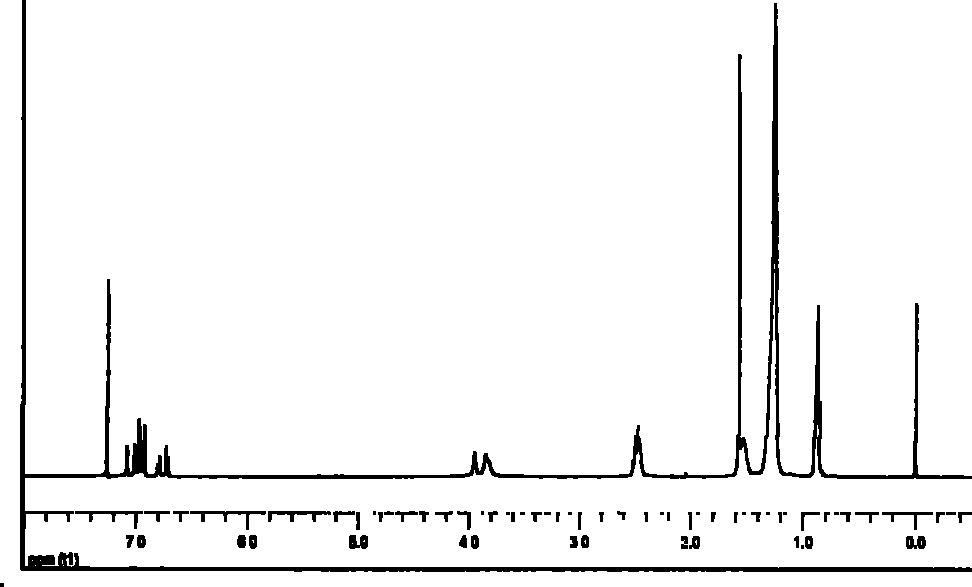

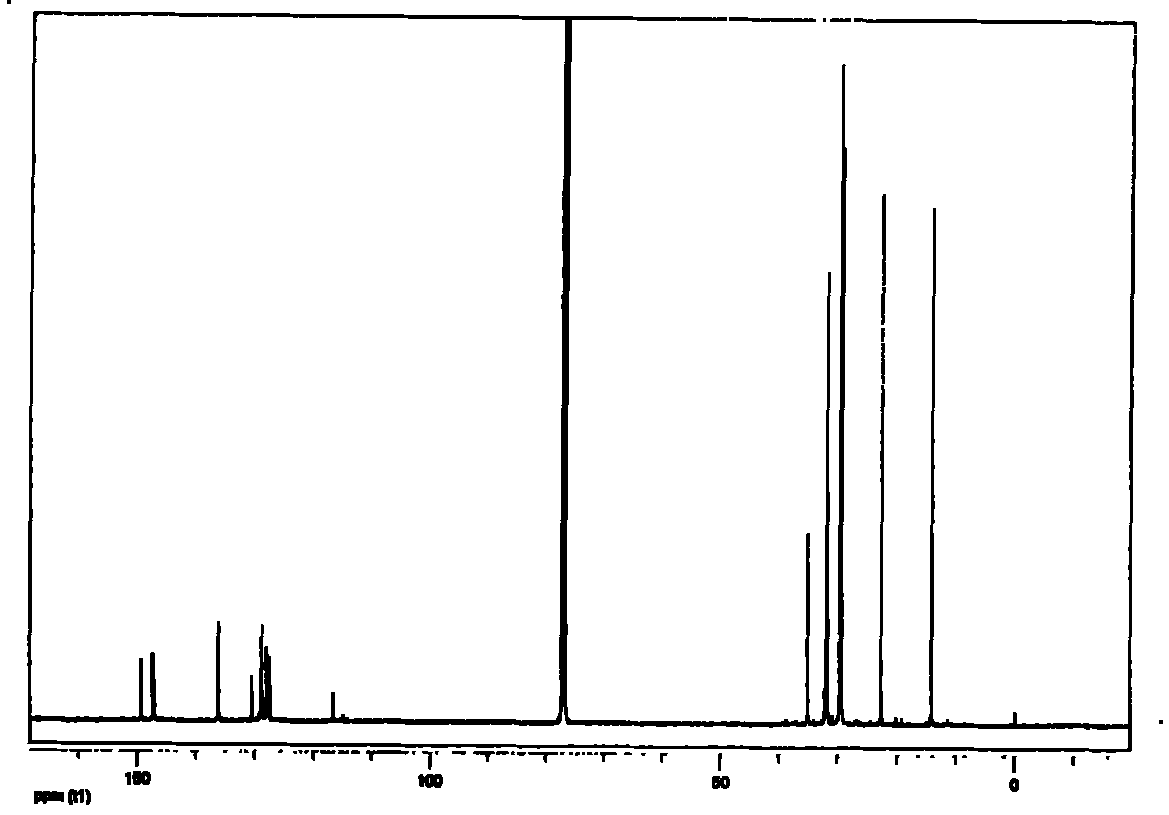

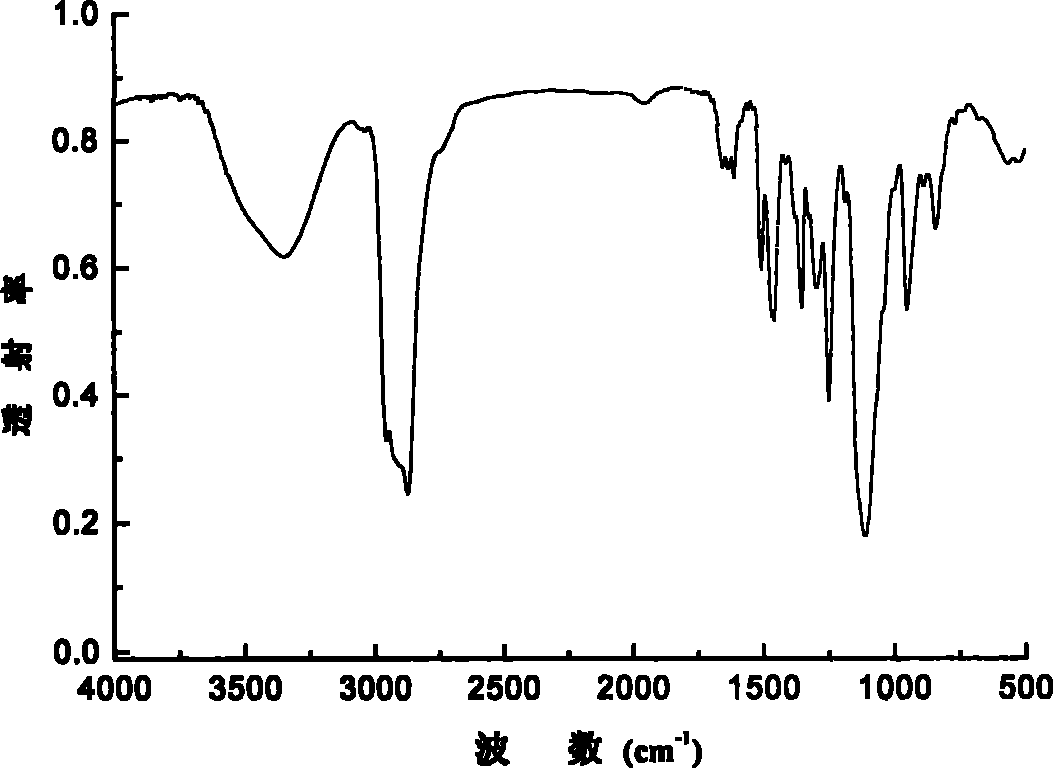

[0032] Synthesis of Decylphenol Polyoxyethylene Ether Trimeric Surfactant TDP-4 (n=10, m=4)

[0033] Synthesis of the first step intermediate 2-[3-(5-decyl salicyl)-5-decyl salicyl]-4-decylphenol

[0034] Add 4-decylphenol and paraformaldehyde in a molar ratio of 4-decylphenol:paraformaldehyde=3:2 to the reactor equipped with a nitrogen protection device, start stirring, and then add the ionic liquid catalyst [ Bmim][BF 4 ], [Bmim][BF 4] is added in an amount of 0.9% of the sum of 4-decylphenol and paraformaldehyde mass, heating and maintaining the temperature of the material is 105 ° C, after reacting for 1 hour, the reaction mixture is extracted with sherwood oil, and then the obtained The extract of the upper layer is distilled, and petroleum ether is steamed out to obtain a trimeric surfactant intermediate: 2-[3-(5-decyl salicyl)-5-decyl salicyl]-4-decylphenol, The yield is 95%; the petroleum ether raffinate of the lower floor obtained by the extraction is stirred with ...

Embodiment 2~23

[0042] In Examples 2 to 23, except the target product listed in the following table 1 (covering its used reactant raw material), ionic liquid catalyst and its addition amount, ethylene oxide addition mole number (mol) Except for the product yield (%), the synthetic reaction steps and other processing conditions are all the same as in Example 1.

[0043] Different ionic liquid catalysts and their dosages are used in Table 1 Examples 2 to 23

[0044]

[0045] 2

Embodiment 24

[0047] Adopt surface tension method to measure the critical micelle concentration of surfactant solution, table 2 is nonylphenol polyoxyethylene ether trimeric surfactant (TNP) and nonylphenol polyoxyethylene ether monomolecular surfactant (NP) Comparison of critical micelle concentration (CMC) values.

[0048] Table 2 CMC values of TNP and NP (25°C)

[0049] monomolecular surfactant

[0050] It can be seen from the above table that the CMC value of TNP is 1-2 orders of magnitude lower than that of NP, and the surface activity is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com