Method for preparing functionalized carbon nanotube based on polyethyleneimine

A polyethyleneimine and carbon nanotube technology is applied in the field of preparation of functionalized carbon nanotubes to achieve the effects of simple preparation process, easy operation and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

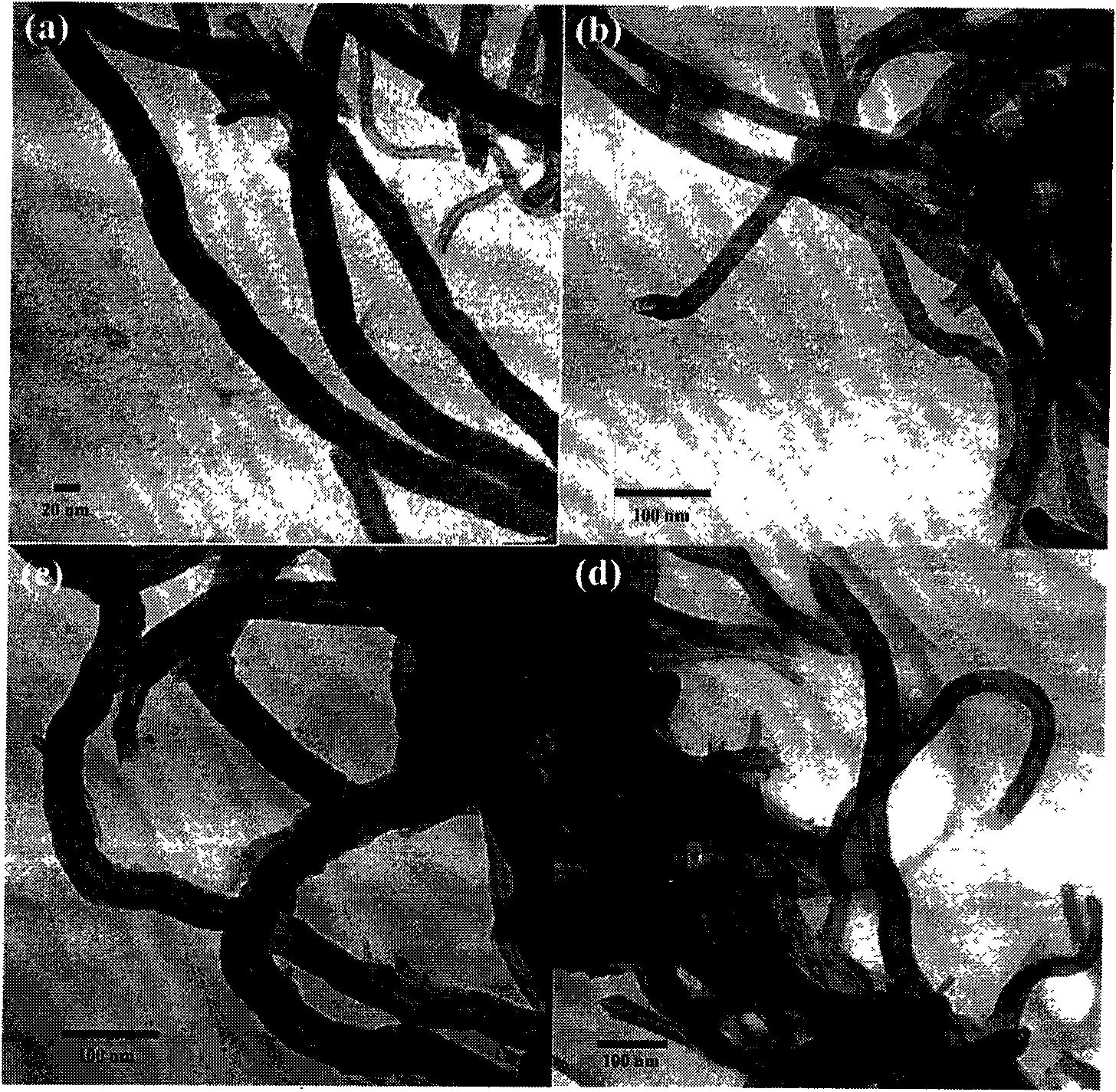

[0046] (1) Configure a mixture of concentrated nitric acid and sulfuric acid with a volume ratio of 3:1 (that is, HNO 3 / H 2 8O 4 is v / v=3:1), carry out acidification treatment to a certain amount of multi-walled carbon nanotubes, after 2 hours, filter, wash with water, and finally place the multi-walled carbon nanotubes after acidification under vacuum condition to dry and store;

[0047] (2) Get 99.8 mg of acidified multi-walled carbon nanotubes in step (1), disperse them in a mixed solution of 20 milliliters of thionyl chloride and 1 milliliter of DMF, and reflux for 24 hours to obtain multi-walled carbon nanotubes containing acid chloride groups on the surface. Reaction product of carbon nanotubes. After the reaction mixture was centrifuged (5000 rpm, 10 minutes) in a high-speed centrifuge, the upper layer solution in the centrifuge tube was poured out. In order to fully remove free thionyl chloride, the centrifuged reaction product should be redispersed in DMF solvent. ...

Embodiment 2

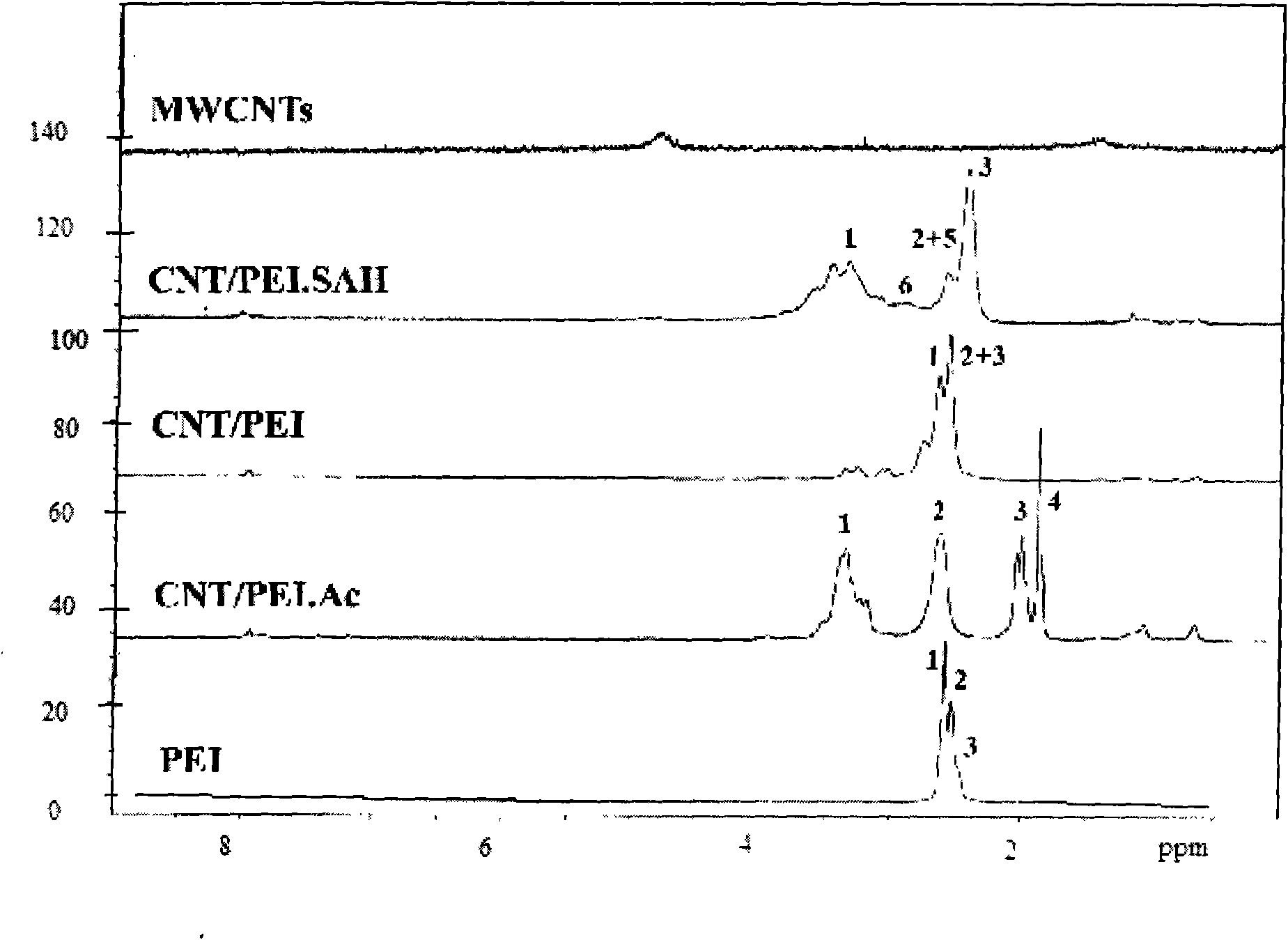

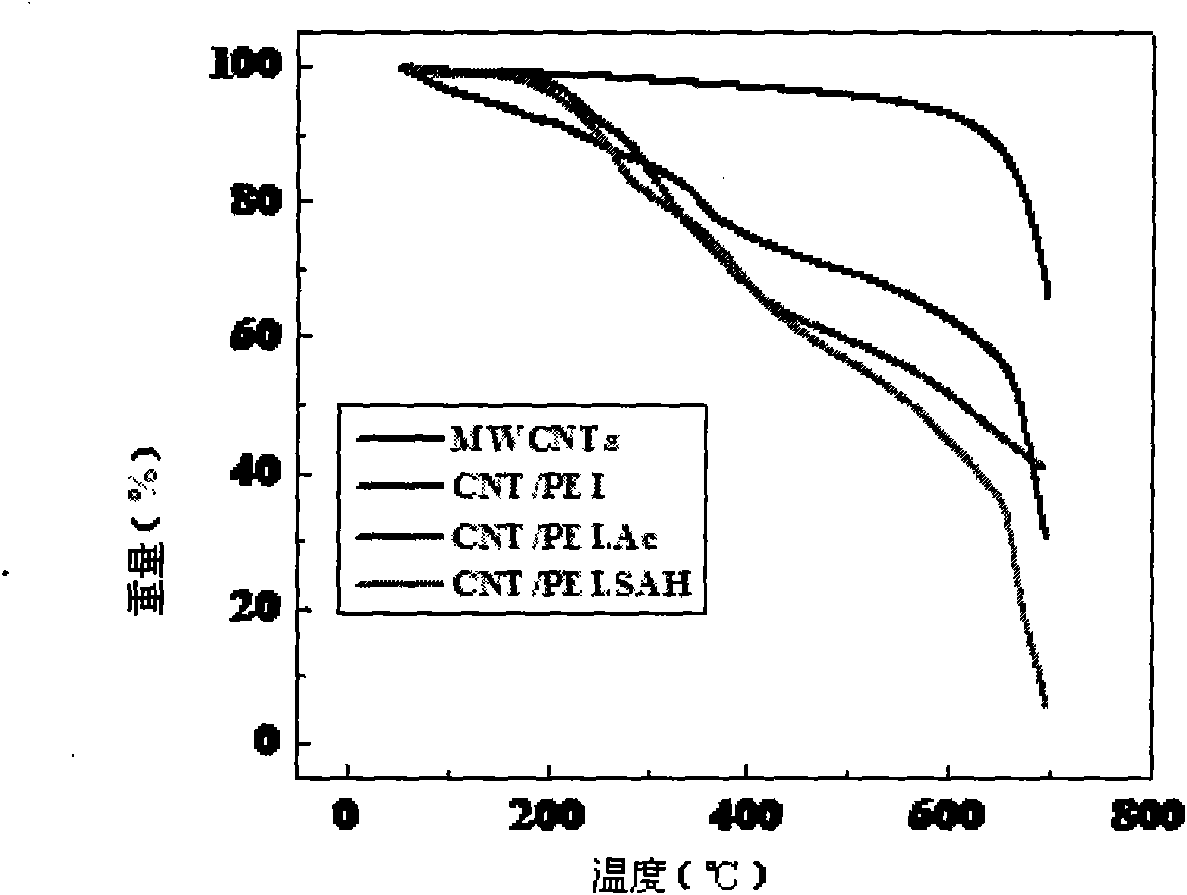

[0051] Take 30 mg of the CNT / PEI carbon nanotubes in Example 1 in a 20 ml vial, add 5 ml of DMSO solvent, and stir magnetically to make it evenly dispersed. Subsequently, 5 ml of DMSO solution containing 410 mg of succinic anhydride was added, and the carboxylation reaction was carried out for 24 hours under strong magnetic stirring. In order to ensure that succinic anhydride and the PEI polymer on the CNT / PEI complex are covalently bonded, we dialyzed the reacted mixture with pure water (3 times, 4 liters) for 3 days with a dialysis membrane of MWCO=50000. Remove the DMF solvent, excess reagents and small molecule by-products produced during the reaction in the reaction mixture. Finally, the purified product CNT / PEI.SAH is freeze-dried to obtain functionalized multi-walled carbon nanotubes with negative surface charges. NMR test shows that the amino group of PEI polymer modified on the surface of multi-walled carbon nanotubes has been successfully converted into the end grou...

Embodiment 3

[0053] (1) Take concentrated nitric acid, acidify a certain amount of single-walled carbon nanotubes, after 3 hours, filter, wash with water, and finally place the acidified single-walled carbon nanotubes under vacuum conditions for drying and then preserve;

[0054](2) Get 105 mg of acidified single-walled carbon nanotubes in step (1), disperse them in a mixed solution of 25 milliliters of thionyl chloride and 1 milliliter of DMF, and reflux for 30 hours to obtain single-walled carbon nanotubes containing acid chloride groups on the surface. Reaction product of carbon nanotubes. After the reaction mixture was centrifuged (5000 rpm, 10 minutes) in a high-speed centrifuge, the upper layer solution in the centrifuge tube was poured out. In order to fully remove free thionyl chloride, the centrifuged reaction product should be redispersed in DMF solvent. And centrifuged again, repeating this 5 times, the last purified single-walled carbon nanotubes containing acid chloride groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com