Acid amide-grafted sodium alginate nanometer material, preparation method thereof and use thereof

A technology of sodium alginate and nanomaterials, applied in chemical instruments and methods, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve the problems of dispersion, small diffusion performance, easy degradation, etc., and achieve improved delivery efficiency , solve the effect of low embedding rate and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

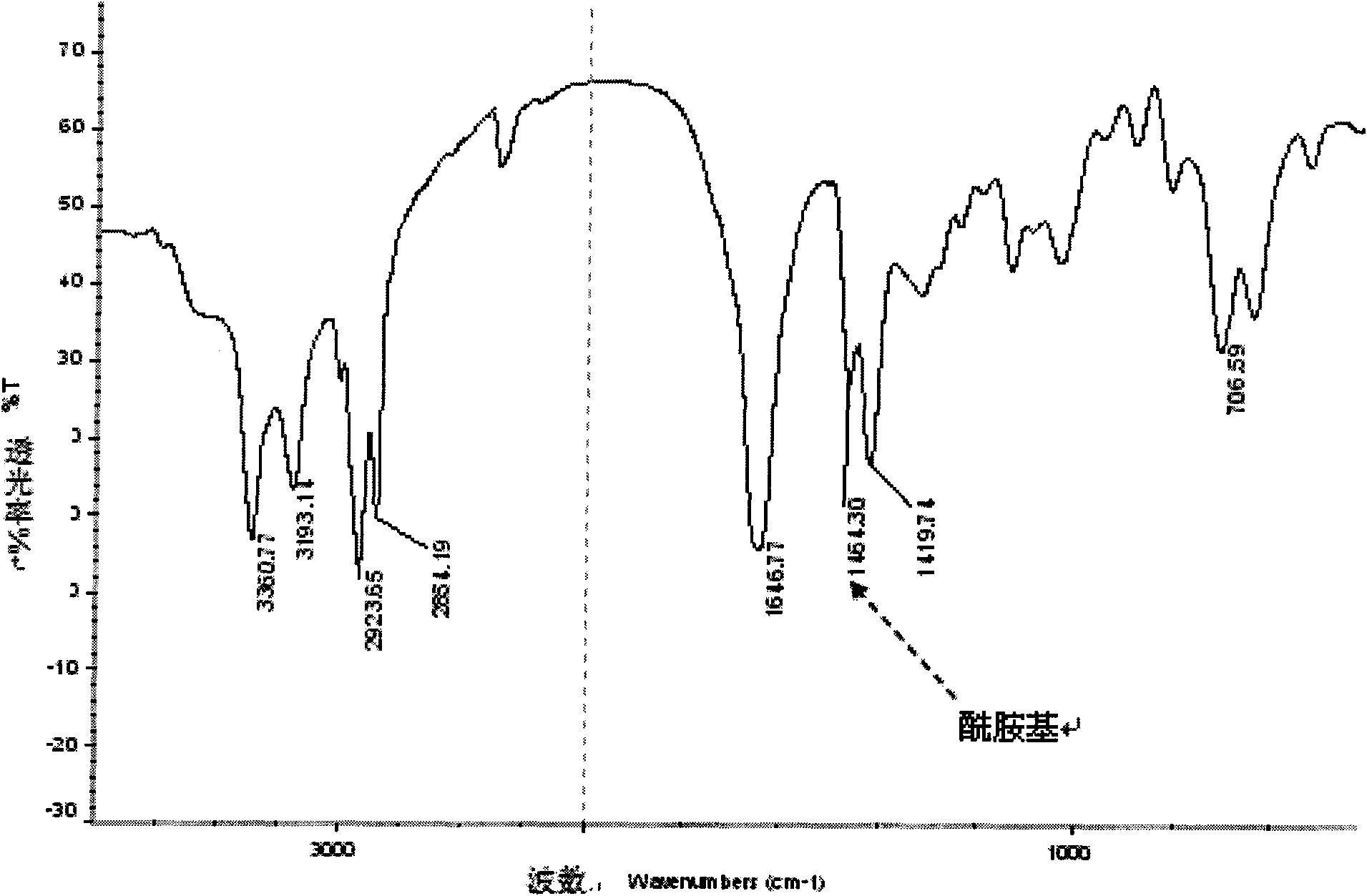

[0021] 3. Preparation of amide grafted sodium alginate material

[0022] (1) Dissolve an appropriate amount of the sample treated in step 2 in DMSO, add amide at a molar ratio of 1:7.5 to 1:18 (alginic acid monomer: amide), and use the molar ratio of sodium alginate monomer and crosslinking agent The ratio is 2:1 ~ 1:5, add cross-linking agent, and react in a sealed water bath at 50°C for 24 hours;

[0023] (2) Put the mixture of the above reaction into a dialysis bag with a molecular weight cut-off of 8-14KDa, dialyze with a sodium salt solution that can replace tetrabutyl cations for 48 hours, change the dialysate 8 times during this period, replace tetrabutyl cations with sodium ions Replaced;

[0024] (3) Take out the dialyzed substance, perform Soxhlet extraction in a water bath at 80° C. for 10 h, and remove unreacted amides;

[0025] (4) drying it at room temperature to get final product;

[0026] The cross-linking agent mentioned in the present invention is a reagen...

Embodiment 1

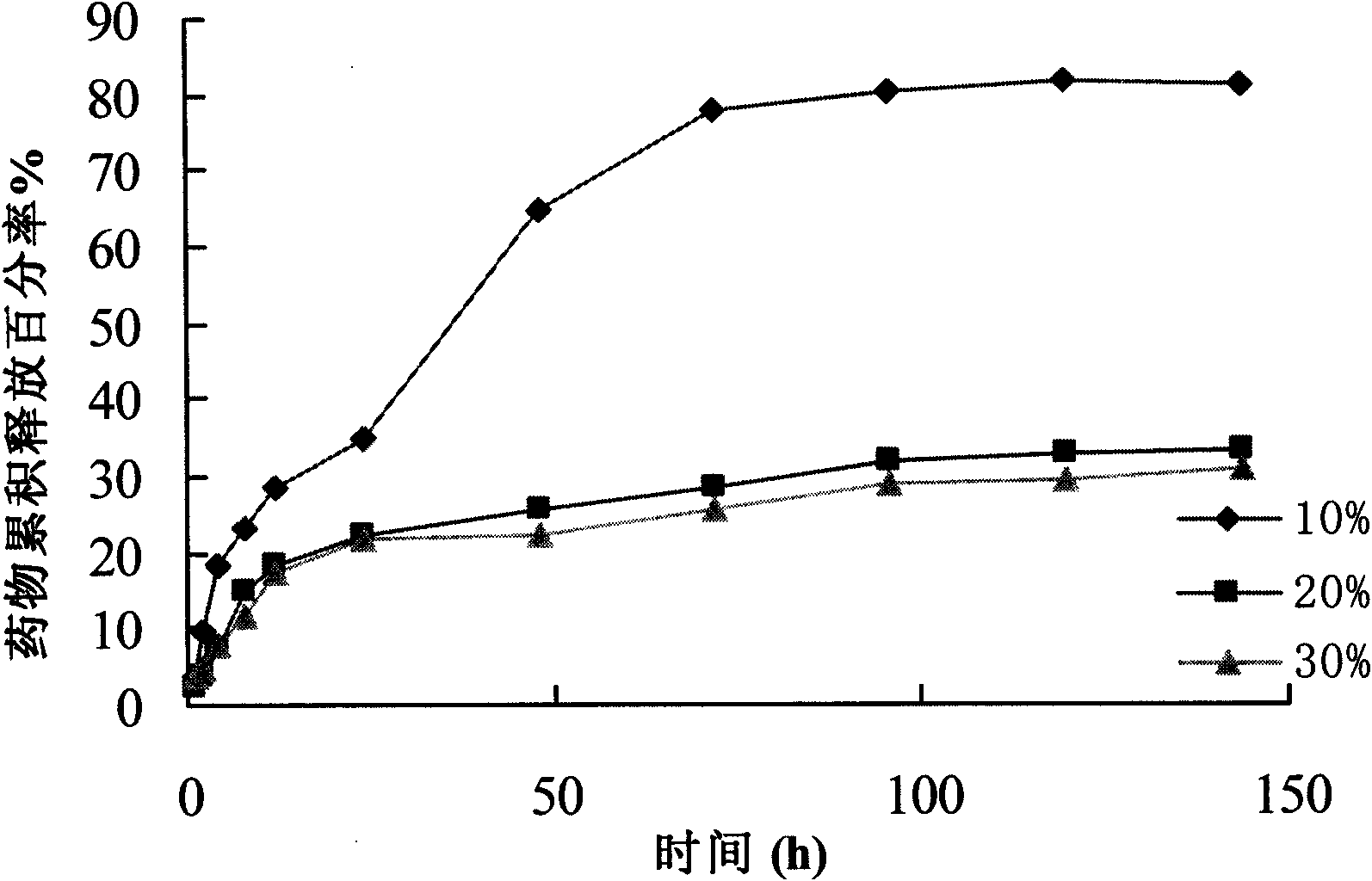

[0029] First, put 20 g of sodium alginate with a molecular weight of 32000, 12.5 ml (0.6 mol / L) of concentrated hydrochloric acid and ethanol with a total volume of 250 ml, stir for 3 hours, store at 0-4°C overnight, and filter and dry the next day to obtain alginic acid; Add 3 g of alginic acid to 50 ml of water, adjust the pH to neutral with tetrabutylammonium hydroxide, and then freeze-dry; then dissolve it in DMSO (dimethyl sulfoxide) at a weight-volume ratio of 2%, and add the Oleamide with a molar ratio of 10:1, and EDC and NHS with a molar ratio of 2:1 to sodium alginate monomer, sealed and reacted in a water bath at 50°C for 24 hours; In a dialysis bag, dialyze with 400 mg / L sodium nitride solution for 48 hours, and change the dialysate 8 times during the period; use methanol as the extraction solution for Soxhlet extraction for 10 hours to remove unreacted oleamide, and dry at room temperature to obtain amide-grafted seaweed Sodium acid material.

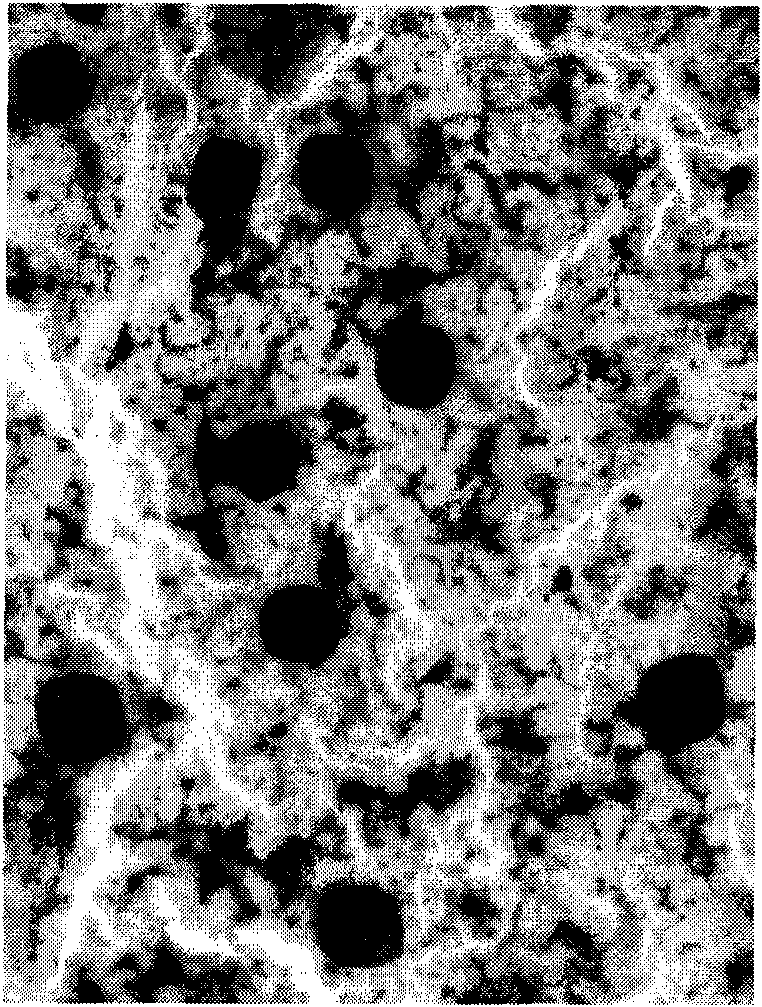

[0030] The hydroph...

Embodiment 2

[0032] First, put 20 g of sodium alginate with a molecular weight of 32000, 12.5 ml (0.6 mol / L) of concentrated hydrochloric acid and ethanol with a total volume of 250 ml, stir for 3 hours, store at 0-4°C overnight, and filter and dry the next day to obtain alginic acid; Add 3 g of alginic acid to 50 ml of water, adjust the pH to neutral with tetrabutylammonium hydroxide, and freeze-dry; then dissolve it in DMSO (dimethyl sulfoxide) at a weight-to-volume ratio of 2%, and add the Oleamide with a molar ratio of 15:1, and EDC and NHS with a molar ratio of 2:1 to sodium alginate monomer, sealed and reacted in a water bath at 50°C for 24 hours; In a dialysis bag, dialyze with 400 mg / L sodium nitride solution for 48 hours, and change the dialysate 8 times during the period; use methanol as the extraction solution for Soxhlet extraction for 10 hours to remove unreacted oleamide, and dry at room temperature to obtain amide-grafted seaweed Sodium acid material.

[0033] The degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com