Water soluble granule of chlorfenapyr and its preparation

A chlorfenapyr and soluble technology, which is applied in the field of water-soluble granules containing chlorfenapyr and its preparation, can solve the problems of no combination of advantages, granulation of solid preparations, etc., achieve less eye irritation, prolong shelf life, and avoid The effect of flammable and explosive phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation process of chlorfenapyr water-soluble granules:

[0035] ①Material preparation: Prepare the raw materials according to the following formula:

[0036] Chlorfenapyr: 1%;

[0037] King phenol polyoxyethylene ether: 3%;

[0038] β-cyclodextrin: 1%;

[0039] Sodium dodecylbenzenesulfonate: 5%;

[0040] Dispersant NNO: 4%;

[0041] Sodium Benzoate: 1%;

[0042] Sodium bicarbonate: 47%;

[0043] Anhydrous citric acid: 38%;

[0044] ②Mix chlorfenapyr, β-cyclodextrin and sodium dodecylbenzene sulfonate in water at 55°C at 420 kg / cm 2 stirring and homogenizing under high pressure, and spray-drying the above-mentioned liquid mixture after homogenization to make a compound parent drug;

[0045] ③ After thermally dissolving vinylphenol polyoxyethylene ether, mix it with dispersant NNO, sodium benzoate, sodium bicarbonate, anhydrous citric acid and compound master drug at 45°C, and then mix it at 6 kg / cm 2 Stir and knead evenly under pressure to obtain a dou...

Embodiment 2

[0052] Preparation process is with embodiment 1, and used raw material formula is:

[0053] Chlorfenapyr: 10%;

[0054] Octylphenol ethoxylate: 6%;

[0055]Benzylphenol polyoxyethylene ether: 1%;

[0056] Sodium lignosulfonate: 3%;

[0057] Fatty amide N-methylsulfonate: 5%;

[0058] Methylcellulose: 2%;

[0059] Sodium Benzoate: 1%;

[0060] Sodium bicarbonate: 37%;

[0061] Anhydrous citric acid: 35%.

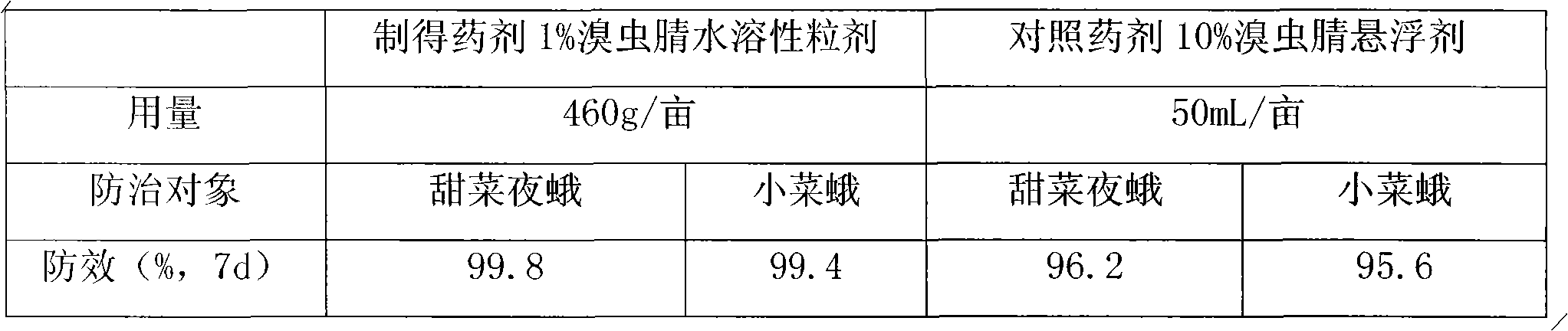

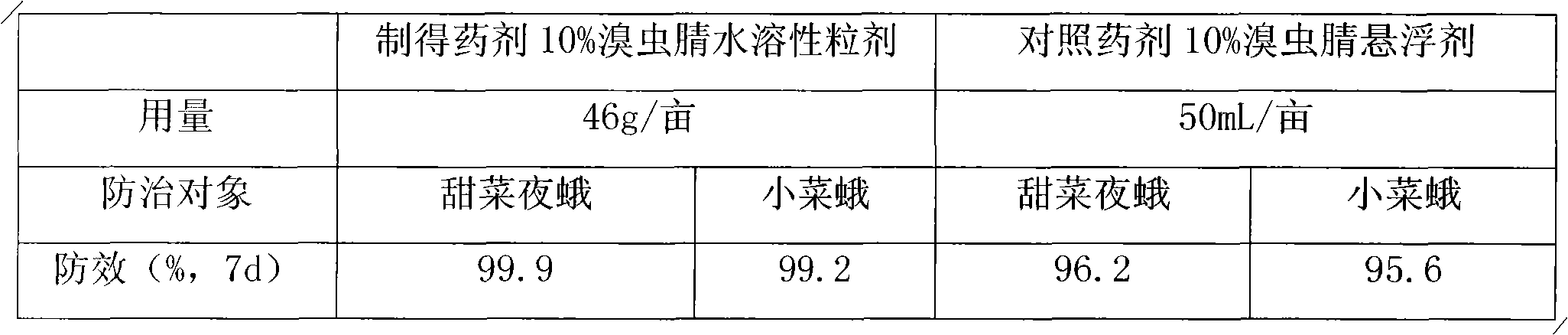

[0062] Use 46g of this preparation per mu to carry out the control test on the cruciferous vegetable pests beet armyworm and diamondback moth. The control effect is good, and the control effect is shown in Table 2:

[0063] Table 2

[0064]

Embodiment 3

[0066] Preparation process is with embodiment 1, and used raw material formula is:

[0067] Chlorfenapyr: 30%;

[0068] Octylphenol ethoxylate: 10%;

[0069] Fatty alcohol polyoxyethylene ether: 2%;

[0070] Dispersant N: 4%;

[0071] Alkylaryl polyoxyethylene ether sulfate: 4%;

[0072] Polyvinyl alcohol: 2%;

[0073] Glucose: 1%;

[0074] Anhydrous sodium sulfate: 27%;

[0075] Anhydrous citric acid: 20%.

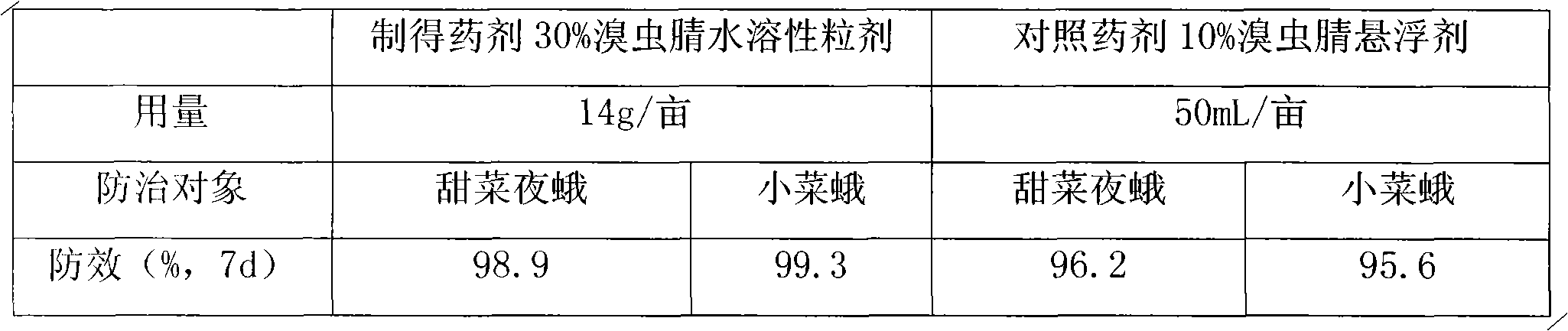

[0076] With this preparation, use 14g per mu to carry out the control test on the cruciferous vegetable pests beet armyworm and diamondback moth. The control effect is good, and the control effect is shown in Table 3:

[0077] table 3

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com