Titanium-coated aluminium laminated composite plate and preparation method thereof

A technology for aluminum composite panels and composite panels, applied in metal layered products, chemical instruments and methods, coatings, etc., can solve problems such as large internal resistance of materials, and achieve good electrical conductivity, uniform current distribution, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

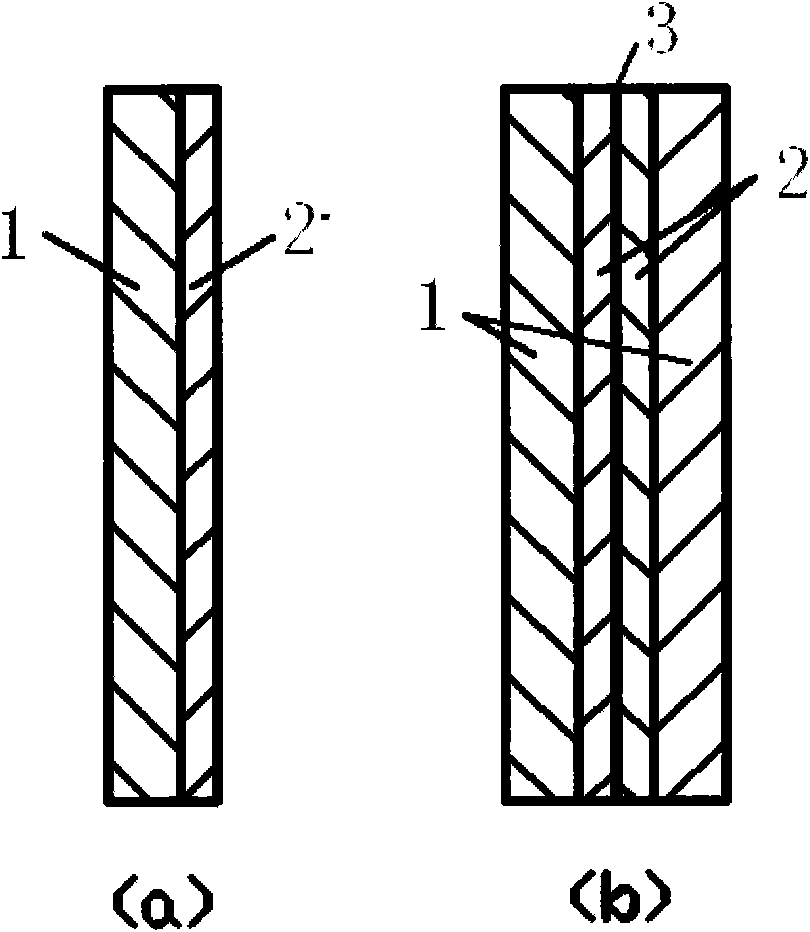

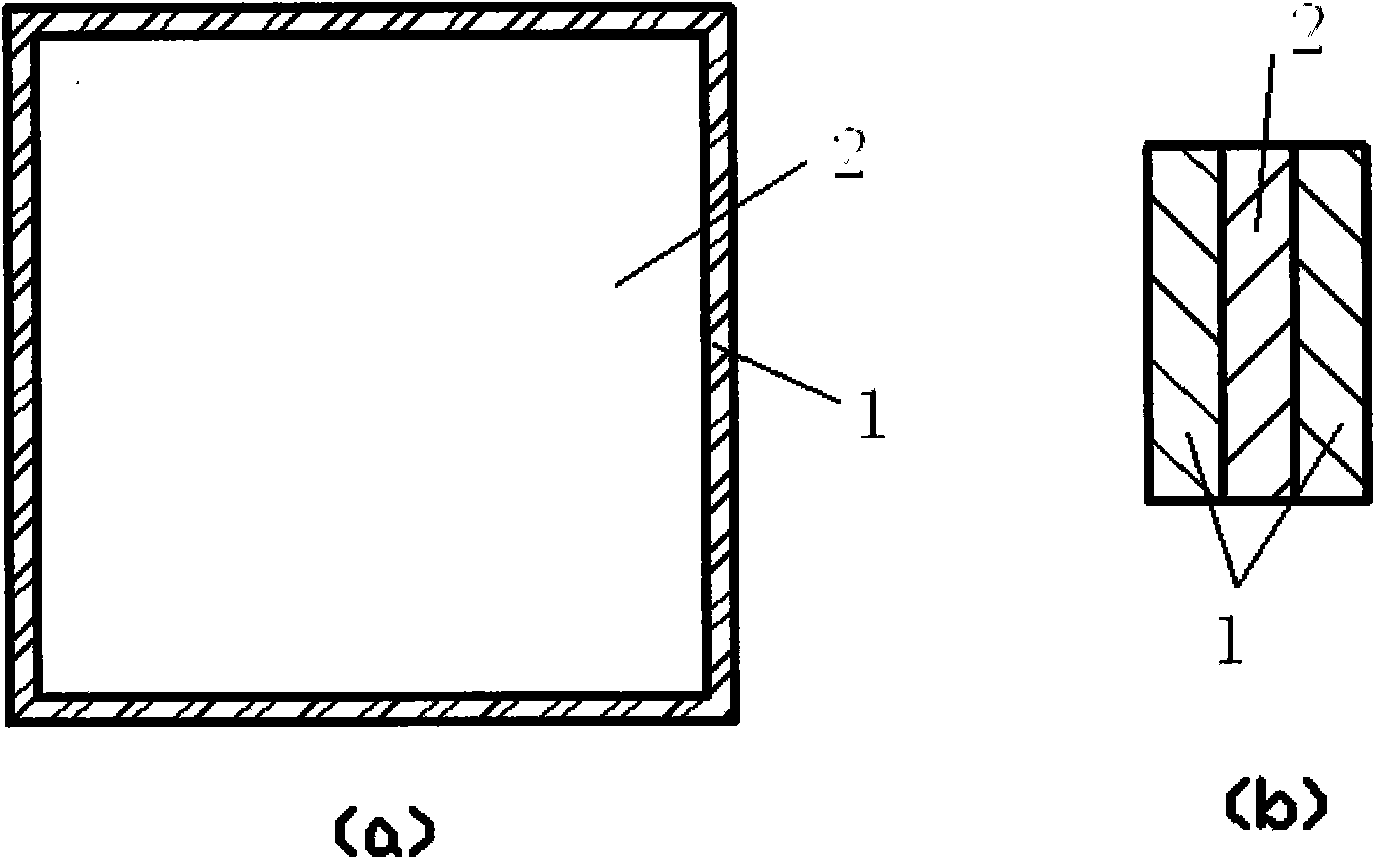

[0025] Example 1 Degrease and sandblast the surface of a 120×120×0.8mm titanium plate, use the working parameters of spraying voltage 32V, current 160A, air pressure 0.5MPa, spraying distance 100mm, CDM-1620 type arc spraying machine on the surface of the titanium plate Spray a 1mm thick aluminum layer on one side, hot-roll at a temperature of 500°C, and then cold-roll to obtain a titanium / aluminum composite plate. Coat the aluminum surfaces of two titanium / aluminum composite plates with a layer of aluminum welding agent, and the aluminum layer A certain pressure is applied relative to the superposition, heat preservation in a heating furnace at 500°C for 60 minutes, cold rolling, and welding by argon arc welding to obtain a titanium-clad aluminum layered composite plate. The coating is applied to electrolysis and the cell voltage is lower than that of pure titanium plates. 15%.

Embodiment 2

[0026] Example 2 Degrease and sandblast the surface of a 120×120×0.8mm titanium plate, and use a CDM-1620 arc spraying machine to spray a 1mm thick aluminum layer with the working parameters of spraying voltage 36V, current 180A, air pressure 0.5MPa, and spraying distance 100mm , hot-rolled at a temperature of 500°C, and then cold-rolled to obtain a titanium / aluminum composite plate. The aluminum surface is coated with a layer of aluminum solder, and a certain pressure is applied to the aluminum layer. It is kept in a heating furnace at 600°C for 60 minutes. Rolling, edge welding by argon arc welding, made of titanium-clad aluminum layered composite plate, coating, applied to the electrolytic cell voltage is 15% lower than that of pure titanium plate.

Embodiment 3

[0027] Example 3 Degrease and sandblast the surface of a 120×120×0.8mm titanium plate, put it into an argon atmosphere deposition chamber, preheat to 300°C and atomize and deposit a 1mm thick aluminum layer on one side, and carry out hot rolling at a temperature of 500°C , and then cold-rolled to obtain a titanium / aluminum composite plate. Coat the aluminum surface of two titanium / aluminum composite plates with a layer of aluminum welding agent. , welded with argon arc welding to make a titanium-clad aluminum composite plate, and the coating is applied to the electrolytic cell voltage, which is 25% lower than that of the pure titanium plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com