Method for preparing seaweed biological long-acting fertilizer

A long-acting fertilizer and seaweed technology, applied in the direction of organic fertilizers, etc., can solve the problem of low active ingredients of seaweed, and achieve the effect of improving the content of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

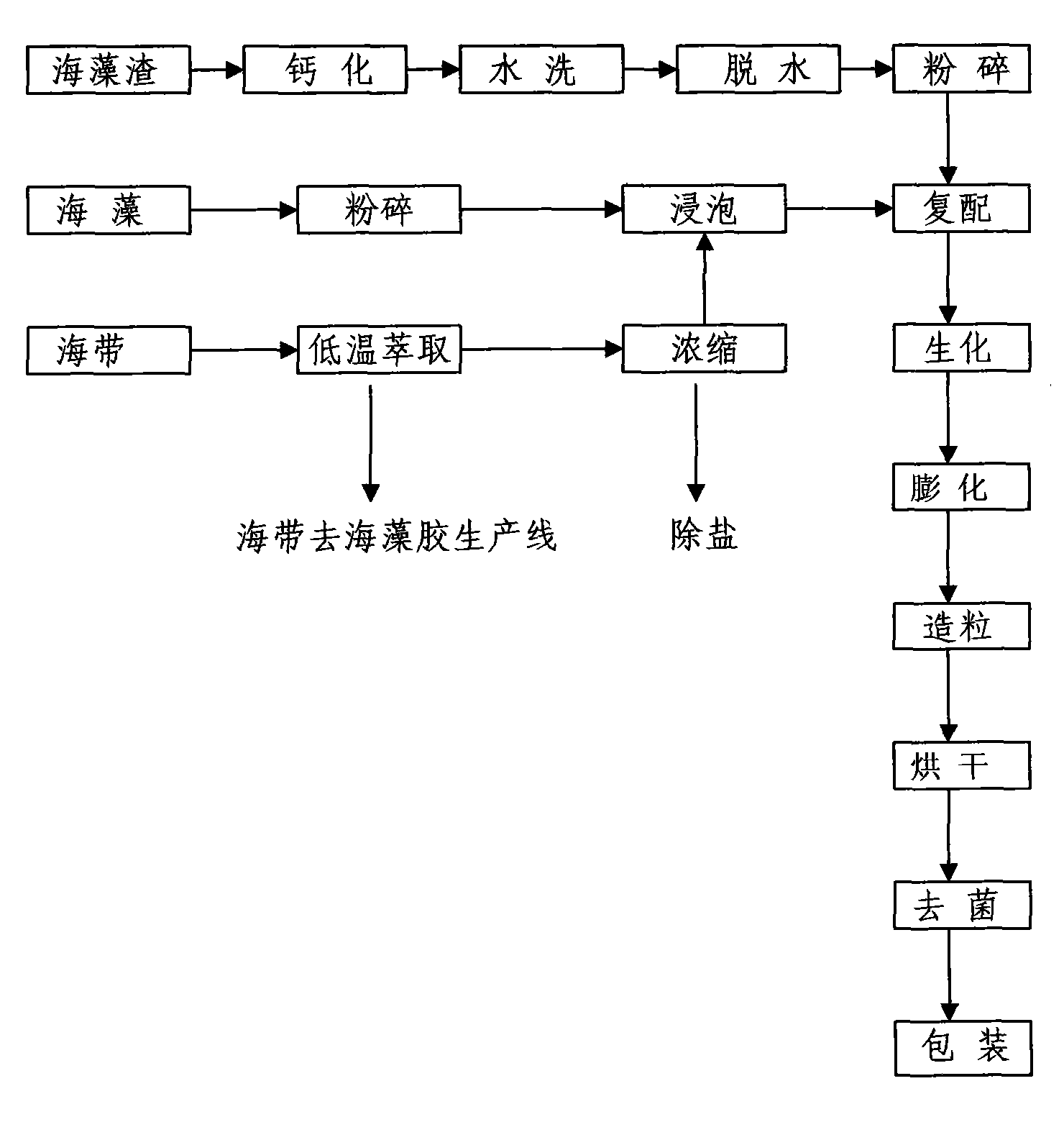

Image

Examples

specific Embodiment 1

[0026] (1) Preparation of seaweed powder active carrier

[0027] Select 10kg of seaweed residue after extracting seaweed gum, carrageenan, and agar gum as raw material, and put it into a calcification tank for calcification. Add hydrochloric acid with a concentration of 1% by weight to make its pH value reach 5, then add 6% calcium chloride solution by weight to make it flocculate completely, and remove the excess calcium chloride and hydrochloric acid solution in the calcified flocs with clear water Rinse well; dehydrate the calcified floc to obtain a dehydrated solid with a water content of 65%; crush the dehydrated solid into a seaweed powder active carrier with a particle size within the range of 4 mesh to 10 mesh for future use.

[0028] (2) Preparation of seaweed mixture

[0029] Wash 5kg of fresh kelp with fresh water, pulverize it with a pulverizer, freeze it at a low temperature for 6 hours, add 15kg of ethanol solution with a concentration of 70% by weight, mix it a...

specific Embodiment 2

[0032] (1) Preparation of seaweed powder active carrier

[0033] Select 10kg of seaweed residue after extracting seaweed gum, carrageenan, and agar gum as raw material, and put it into a calcification tank for calcification. Add hydrochloric acid with a concentration of 1.5% by weight to make its pH value reach 5, then add 10% calcium chloride solution by weight to make it flocculate completely, and use clear water to dissolve the excess calcium chloride and hydrochloric acid solution in the calcified flocs Rinse well; dehydrate the calcified flocs to obtain dehydrated solids with a water content of 75%; crush the dehydrated solids into seaweed powder active carriers with particle sizes ranging from 4 mesh to 20 mesh for future use.

[0034] (2) Preparation of seaweed mixture

[0035] Wash 5kg of fresh kelp with fresh water, pulverize it with a pulverizer, freeze it at a low temperature for 4 hours, add 15kg of ethanol solution with a concentration of 80% by weight, mix it an...

specific Embodiment 3

[0038] (1) Preparation of seaweed powder active carrier

[0039] Select 10kg of seaweed residue after extracting seaweed gum, carrageenan, and agar gum as raw material, and put it into a calcification tank for calcification. Add hydrochloric acid with a concentration of 2% by weight to make its pH value reach 5.5, then add 8% calcium chloride solution by weight to make it flocculate completely, and remove the excess calcium chloride and hydrochloric acid solution in the calcified flocs with clear water Rinse well; dehydrate the calcified flocs to obtain dehydrated solids with a water content of 60%; crush the dehydrated solids into seaweed powder active carriers with particle sizes ranging from 15 mesh to 20 mesh for future use.

[0040] (2) Preparation of seaweed mixture

[0041] Wash 5kg of fresh kelp with fresh water, pulverize it with a pulverizer, freeze it at a low temperature for 8 hours, add 15kg of ethanol solution with a concentration of 75% by weight, mix it and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com