Environmental-friendly polypropylene compatilizer preparation method

A polypropylene and compatibilizer technology, applied in the field of polymer science, can solve problems such as excessive maleic anhydride residue, strong taste of maleic anhydride, difficult solvent environment, etc., and achieve excellent processing stability and ultra-low acid anhydride residue , Improve the effect of processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First add 600 grams of homopolypropylene (molecular weight is 50,000), 200 grams of maleic anhydride, 50 grams of dibenzoyl peroxide, 100 grams of acrylamide, and 50 grams of four [beta-(3 ', 5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester, at 50 DEG C and 3000 rpm solid phase grafting reaction for 2 hours, prepared polypropylene initiator masterbatch, then the above prepared After mixing 2% of polypropylene masterbatch and 98% of homopolypropylene (molecular weight: 300,000) on a high-speed mixer at room temperature at 2400 rpm, the melting temperature on a twin-screw extruder is 170°C and the speed is 60 rpm Carry out the grafting reaction of melt extrusion, obtain the grafting material of maleic anhydride polypropylene with low odor with grafting rate of 1.0% and residual acid anhydride less than 0.5%.

Embodiment 2

[0031] First, add 900 grams of homopolypropylene (molecular weight: 100,000), 80 grams of maleic anhydride, 3 grams of ditert-butyl peroxide, 5 grams of acrylic acid, 6 grams of triphenyl phosphite and 6 grams of thiophene in the autoclave. Dilauryl dipropionate, at 120 ℃ and 2400 rpm solid phase grafting reaction for 0.5 hour, prepared polypropylene masterbatch, then the polypropylene masterbatch 30% prepared above was mixed with homopolypropylene (molecular weight: 1,200,000) 70% mixed at room temperature at 3000 rev / min on a high-speed mixer, then melted and extruded at 300 rev / min at a twin-screw extruder with a melting temperature of 220 °C and a grafting reaction of 300 rev / min, to obtain a grafting rate of 1.2% maleic anhydride polypropylene grafting material with low odor and less than 0.2% residual acid anhydride.

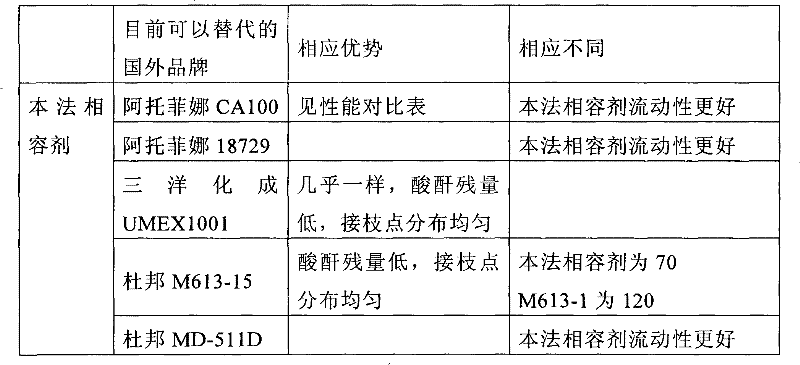

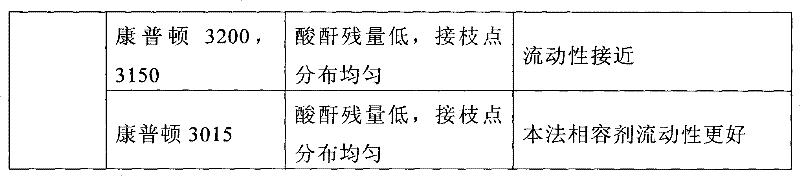

[0032] The maleic anhydride grafted polypropylene compatibilizer prepared by the method of the invention has high grafting rate, low acid anhydride residu...

Embodiment 3

[0045]First, add 950 grams of homopolypropylene (molecular weight is 2 million), 10 grams of maleic anhydride, 1 gram of azobisisobutyronitrile, 38 grams of α-methacrylic acid, 1 gram of N, N'-bis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl] hydrazine, at 130 DEG C and 300 rev / min solid-phase grafting reaction 0.2 hour, prepared polypropylene initiator masterbatch, then 40% of the above prepared polypropylene masterbatch and 60% of homopolypropylene (molecular weight is 1.2 million) are mixed at room temperature at 1200 rpm on a high-speed mixer, and the melting temperature on the twin-screw extruder is 240° C. and the rotating speed is 600 Rotation per minute to carry out the grafting reaction of melt extrusion to obtain a low-odor maleic anhydride polypropylene graft material with a graft rate of 1.0% and an anhydride residue of less than 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com