Method for preparing metal-doped low-energy gap nanocrystalline semiconductor photo-anode film

A metal doping, semiconductor technology, applied in the field of solar cells, can solve the problems of high cost of toxic by-products, limit the general application of silicon solar cells, etc., achieve good energy level matching effect, improve electron transfer efficiency, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

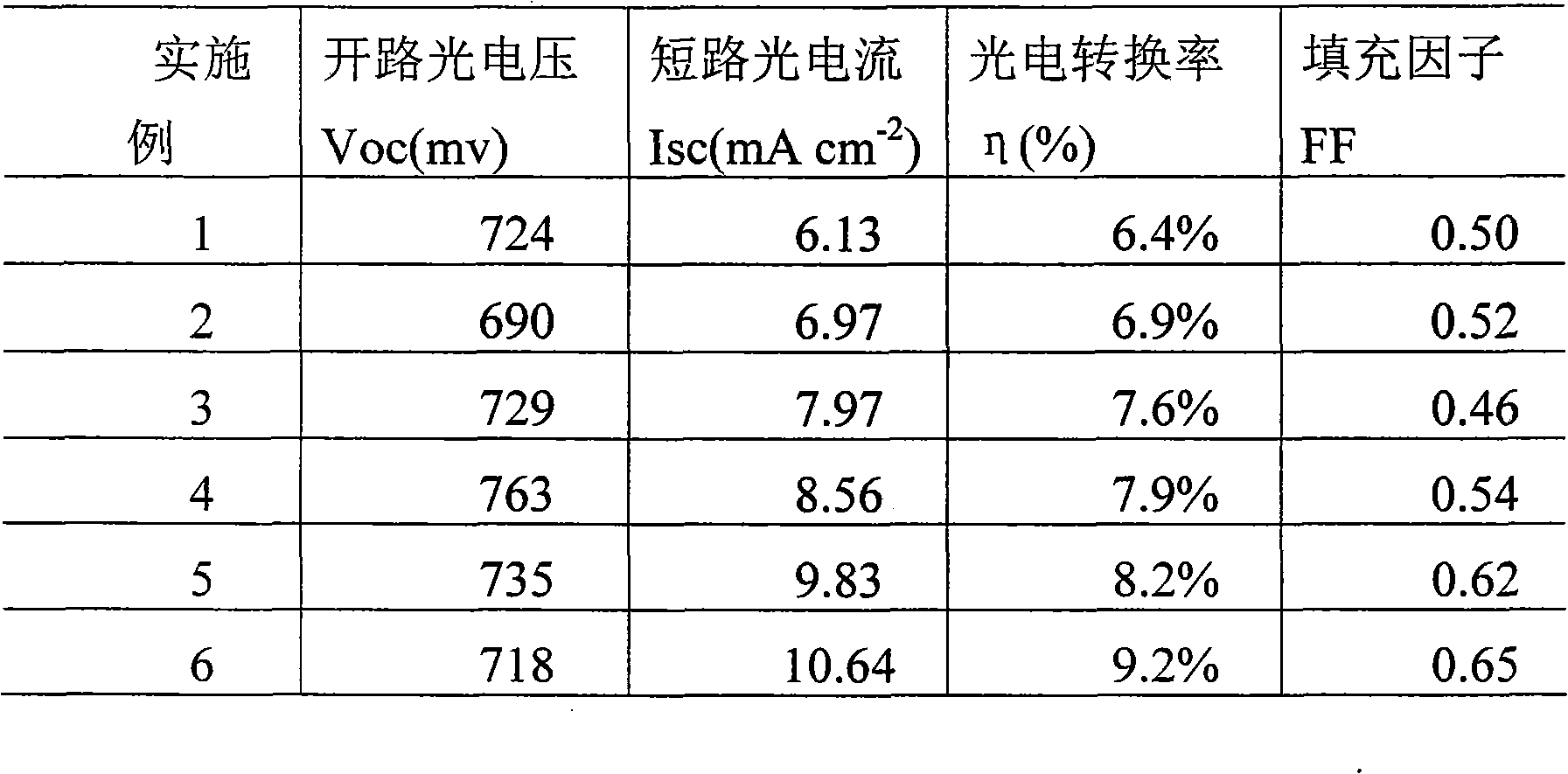

Examples

example 1

[0023] 1). Take 10ml 1M TiCl 4 Put hydrochloric acid aqueous solution in a beaker, measure 1ml of 0.2M ferric nitrate solution, the molar ratio of titanium salt to iron salt is 100; Oxyethylene ether AEO-3, after stirring evenly for 20 minutes, add 3M ammonia water precipitation agent at a rate of 3 seconds per drop to make it precipitate, and when the precipitation reaches pH=6, continue stirring for 1 hour, and let it stand for aging for 24 hours. It was washed with deionized water four times and alcohol exchanged twice, centrifuged, dried for 48 hours, and calcined at 500°C for 1 hour to obtain iron-doped nano-titanium dioxide powder A.

[0024] 2). Take 10ml 4M TiCl 4 Put aqueous hydrochloric acid solution in a beaker, add 10ml of absolute ethanol to it, and finally add 1ml of 0.2M iron nitrate solution, the molar ratio of titanium salt to iron salt is 100:0.5, stir for 2h, and age for 24h to obtain iron-doped nano Titanium dioxide sol B.

[0025] 3) Spin coating at a l...

example 2

[0029] 1). Take 10ml 4M TiCl 4 Put hydrochloric acid aqueous solution in a beaker, measure 3ml 0.2M ferric nitrate solution, make the molar ratio of titanium salt to iron salt 100:1.5, add it dropwise into titanium tetrachloride hydrochloric acid solution, and stir vigorously, add 10 drops of fatty alcohol poly Oxyethylene ether AEO-3, after stirring evenly for 20 minutes, add 3M ammonia water precipitation agent at a rate of 3 seconds per drop to make it precipitate, and when the precipitation reaches pH=9, continue stirring for 1 hour, and let it stand for aging for 24 hours. It was washed with deionized water four times and alcohol exchanged twice, centrifuged, dried for 48 hours, and calcined at 500°C for 1 hour to obtain iron-doped nano-titanium dioxide powder A.

[0030] 2). Take 10ml 4M TiCl 4 Put hydrochloric acid aqueous solution in a beaker, the concentration of hydrochloric acid is 6M, add 10ml of absolute ethanol to it, and finally add 3ml of 0.2M ferric nitrate s...

example 3

[0035] 1). Take 10ml 4M TiCl 4 Put hydrochloric acid aqueous solution in a beaker, measure 2ml of 0.5M tin chloride solution, make the molar ratio of titanium salt to tin salt 100:5, add it dropwise into titanium tetrachloride hydrochloric acid solution, stir vigorously, add 10 drops of fatty alcohol Polyoxyethylene ether AEO-3, after stirring evenly for 20 minutes, add 3M ammonia water precipitant at a rate of 3 seconds per drop to make it precipitate, and when the precipitation reaches pH=9, continue stirring for 1 hour, and let stand for aging for 24 hours. It was washed with deionized water four times and alcohol exchanged twice, centrifuged, dried for 48 hours, and calcined at 500°C for 1 hour to obtain tin-doped nano-titanium dioxide powder A.

[0036] 2). Take 10ml 4M TiCl 4 Put hydrochloric acid aqueous solution in a beaker, add 10ml of absolute ethanol to it, and finally 2ml of 0.5M tin chloride solution, the molar ratio of titanium salt to tin salt is 100:5, stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com