Adjustable microwave band-pass filter

A filter and microwave band technology, applied in waveguide devices, image communication, optical waveguide coupling, etc., can solve the problems of large volume control power consumption devices, increased process difficulty and cost, and difficulty in miniaturization, so as to reduce failure Probability, improvement of overall performance, effect of reducing microwave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] The micro-machine adjustable microwave dual-mode band-pass filter of the present invention adopts a dual-mode ring filter structure with adjustable resonance characteristics. Take the microstrip transmission line as an example to illustrate its structure and working principle.

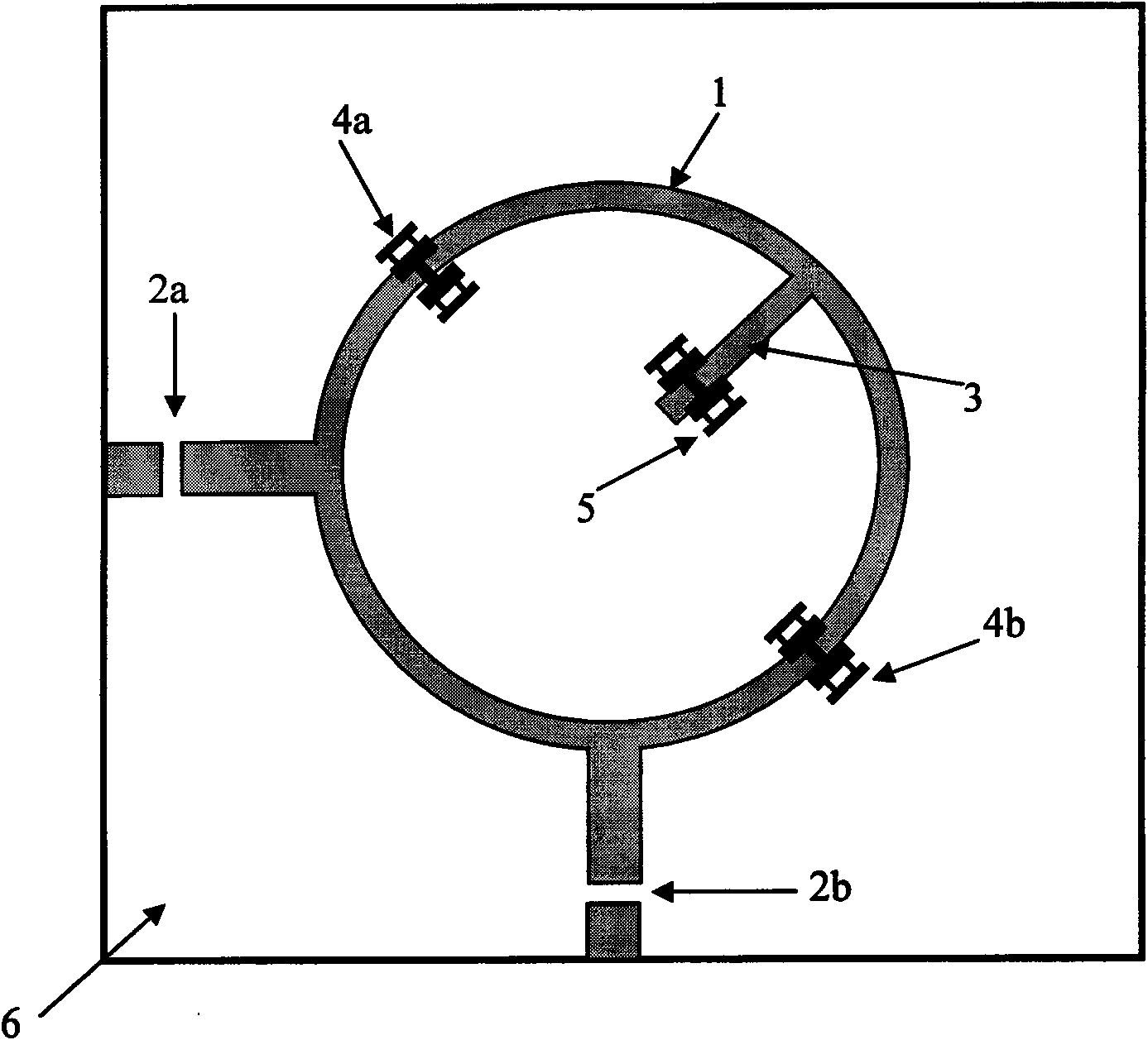

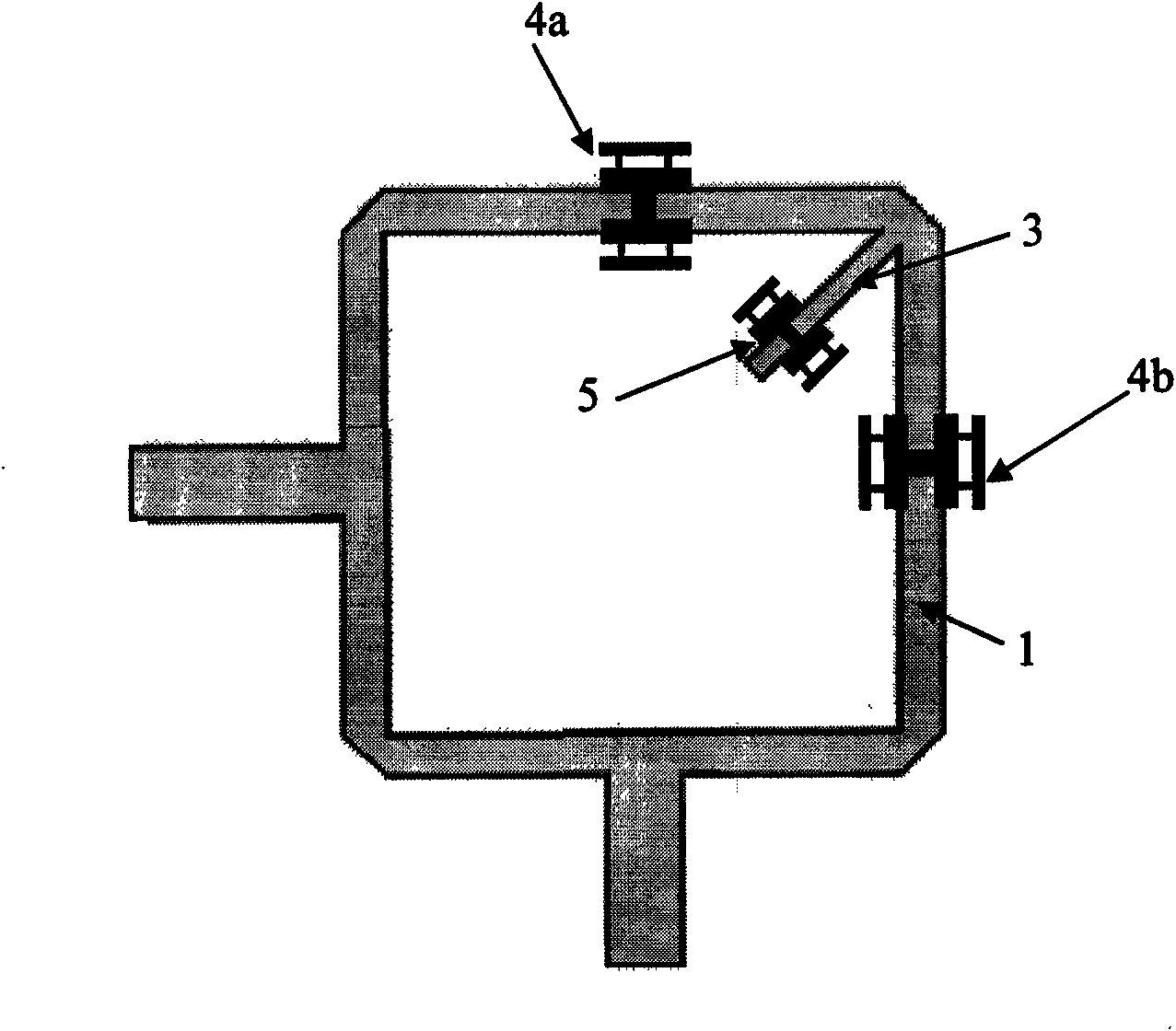

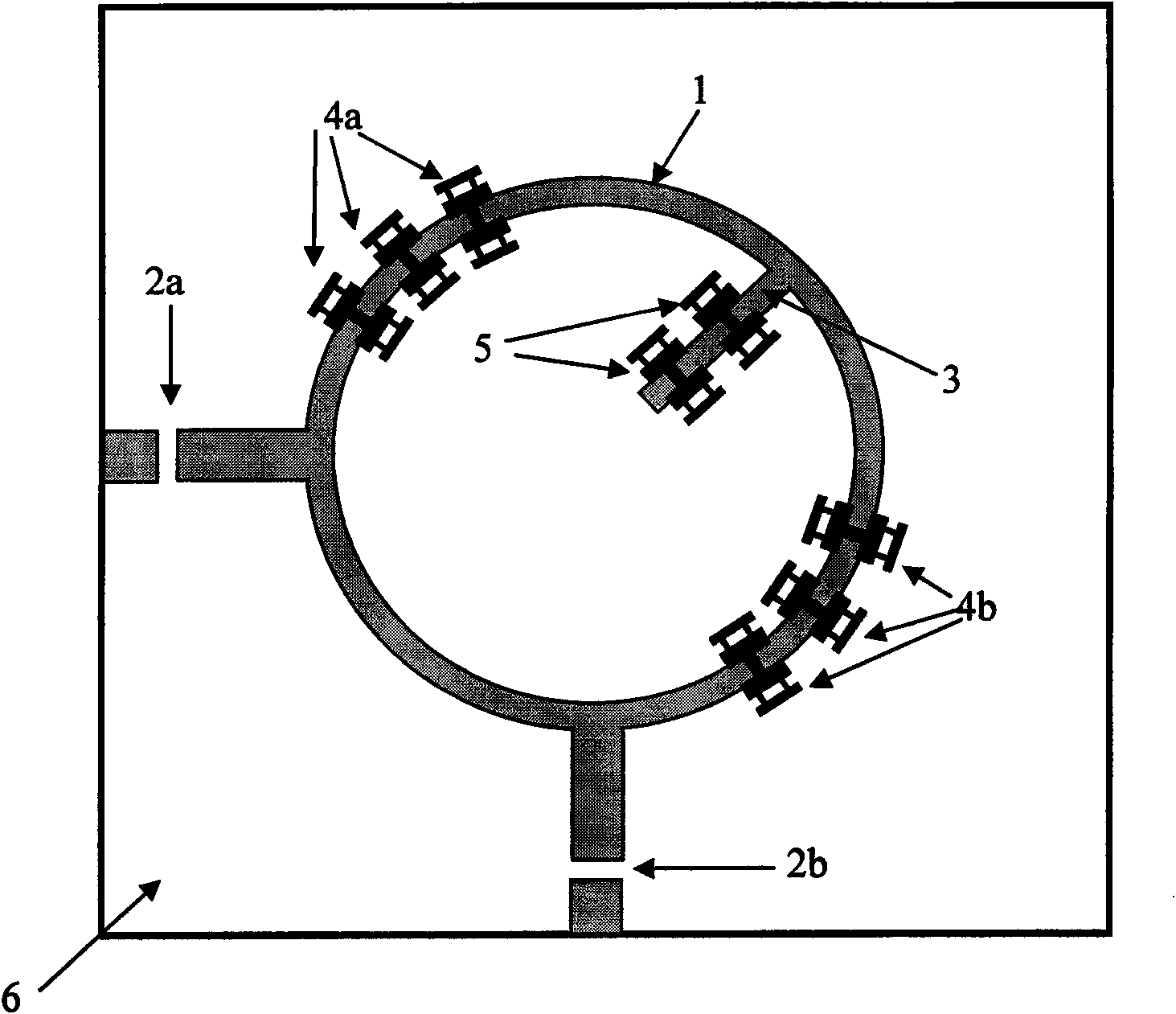

[0037] The basic circuit structure of the dual-mode filter is as figure 1 As shown, it includes a dual-mode ring resonator 1 ( figure 1 The axis of the microstrip line is a circular ring, but it can also be a square ring or a closed-loop figure with fractal characteristics), and the capacitively coupled input coupling unit 2a, output coupling unit 2b, and disturbance unit 3 play the role of central frequency adjustment The micromechanical bridging membranes 4a, 4b and the micromechanical bridging membrane 5 for adjusting the passband bandwidth. The microwave si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com