Phenol formaldehyde adhesive synthesized by using waste preservative timber and preparation method thereof

A phenolic resin and adhesive technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of increased residue rate, etc., and achieve the effect of improving comprehensive utilization rate and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

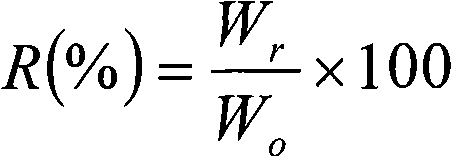

Method used

Image

Examples

Embodiment 1

[0049] 1. Crushing of waste preservative wood

[0050] The waste anti-corrosion wood Chinese fir after being treated with CCA (copper chromium arsenic water-soluble preservative) is crushed into wood powder, and the particle size of the wood powder is 80 mesh;

[0051] 2. Liquefaction of wood flour

[0052] 1) wood powder, phenol, catalyst sulfuric acid solution and polymerization inhibitor tetralin are added to a three-necked glass bottle and mixed uniformly, wherein the mass percentage concentration of sulfuric acid solution is 36%; the weight ratio of wood powder and phenol is 1: 3; the weight ratio of sulfuric acid solution and phenol is 6: 100; the weight ratio of tetralin and phenol is 20: 100;

[0053] 2) Place the three-necked glass bottle in an oil bath preheated to 150°C, install a condenser, stir and mix well, and carry out liquefaction treatment of wood powder at 150°C to obtain a liquefaction treatment mixture, wherein the stirring rate is 1058rpm ; The liquefac...

Embodiment 2

[0067] 1. Crushing of waste preservative wood

[0068] The waste antiseptic wood Populus tomentosa treated with ACQ preservative (a water-soluble preservative compounded with ammonia-soluble alkylamine copper quaternary ammonium salt and copper salt) is pulverized into wood powder, and the particle size of the wood powder is 20 mesh;

[0069] 2. Liquefaction of wood flour

[0070] 1) Add poplar wood powder, phenol, sulfuric acid solution and decahydronaphthalene into a three-necked glass bottle and mix evenly, wherein the mass percentage concentration of the sulfuric acid solution is 40%; the weight ratio of wood powder and phenol is 1: 4; The weight ratio of solution and phenol is 8: 100; The weight ratio of decalin and phenol is 25: 100;

[0071] 2) Put the three-necked glass bottle in an oil bath preheated to 160°C, install the condenser, stir and mix well, and carry out liquefaction treatment of wood powder at 160°C to obtain a liquefaction treatment mixture, wherein the ...

Embodiment 3

[0082] 1. Crushing of waste preservative wood

[0083] The waste anticorrosion wood masson pine after ACQ (water-soluble preservative compounded with ammonia-soluble alkylamine copper quaternary ammonium salt and copper salt) preservative treatment is pulverized into wood powder, and the particle size of the wood powder is 50 orders;

[0084] 2. Liquefaction of wood flour

[0085] 1) Add wood powder, phenol, sulfuric acid solution and ethylene carbonate to a three-necked glass bottle and mix evenly, wherein the mass percent concentration of the sulfuric acid solution is 30%; the weight ratio of wood powder and phenol is 1:5; the sulfuric acid solution The weight ratio with phenol is 10:100; the weight ratio of ethylene carbonate and phenol is 15:100;

[0086] 2) Place the three-necked glass bottle in an oil bath preheated to 150°C, install a condenser, stir and mix well, and carry out liquefaction treatment of wood powder at 150°C to obtain a liquefaction treatment mixture, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com