Preparation method of double-network hydrogel

A technology of hydrogel and double network, applied in the field of preparation of hydrogel, can solve the problems of poor tensile properties of double network hydrogel, cumbersome polyethylene glycol steps, low water content of hydrogel, etc. The effect of mechanical properties, high water absorption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

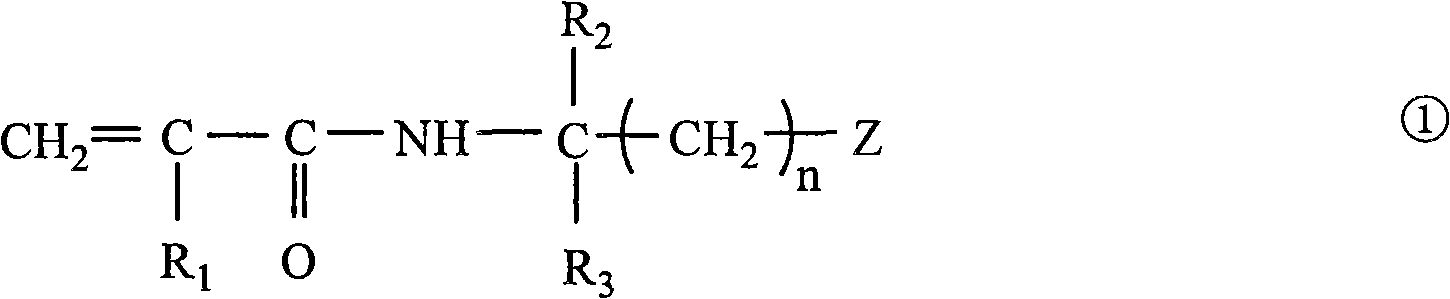

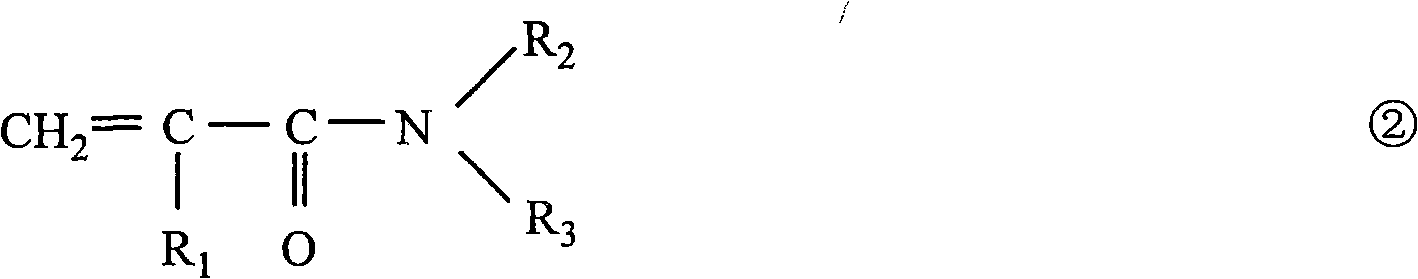

Method used

Image

Examples

Embodiment 1

[0042] Weigh 1.04g of 2-acrylamide-2-methylpropanesulfonic acid, cross-linking agent N, N'-methylenebisacrylamide 0.03g, initiator α-ketoglutarate 0.009g, polyethylene glycol ( Molecular weight 20000) 1.0g, then add 5mL deionized water, dissolve evenly, pour this solution into a silicone sheet mold, 2000 watts of strong ultraviolet radiation for 30s, to obtain a single network gel. Weigh 21.4g of acrylamide, 0.04g of cross-linking agent N,N'-methylenebisacrylamide, 0.1g of initiator α-ketoglutaric acid, add 150mL of deionized water, and mix evenly. In this solution, until the swelling is balanced, take it out, and irradiate it with weak ultraviolet light at 15 watts for 12 hours to obtain a high-strength double-network hydrogel. The hydrogel can absorb water 12 times its own weight, has a tensile strength of 0.45MPa, a breaking elongation of 260%, a compressive strength of 15MPa, and a compressive deformation rate of over 99%.

Embodiment 2

[0046] Weigh 0.01g of 2-methacrylamide-2-methylpropanesulfonic acid, cross-linking agent N, N'-methylenebismethacrylamide 0.075g, initiator 2,4,6 (trimethylbenzene Formyl)diphenylphosphine oxide 0.025g, ammonium sulfate 0.05g, and then add 5mL of deionized water to dissolve evenly, pour this solution into a silica gel sheet mold, and irradiate with 4000 watts of strong ultraviolet light for 3s to obtain a single network gel. Weigh 0.4g of acrylic acid, 0.008g of crosslinking agent N,N'-methylenebismethacrylamide, 0.36g of initiator 2,4,6(trimethylbenzoyl)diphenylphosphine oxide, add 40mL Deionized water, mixed evenly, put the single-network gel in this solution until the swelling is balanced, take it out, and irradiate it with 100 watts of weak ultraviolet light for 0.5h to obtain a high-strength double-network hydrogel. The hydrogel can absorb water 15 times its own weight, has a tensile strength of 0.35 MPa, a breaking elongation of 230%, a compressive strength of 10 MPa, an...

Embodiment 3

[0048] Take by weighing 2.5g of 2-acrylamide-2-methylpropanesulfonic acid, crosslinking agent N, N'-methylenebisacrylamide 0.001g, initiator α-ketoglutaric acid 0.0025g, polyoxyethylene (molecular weight 500000) 0.25g, then add 5mL deionized water, dissolve evenly, pour this solution into a silicone sheet mold, and irradiate with 2000 watts of strong ultraviolet light for 300s to obtain a single network gel. Weigh 2.5g of acrylamide, 0.35g of cross-linking agent N,N'-methylenebisacrylamide, 0.0045g of initiator α-ketoglutaric acid, add 50mL of deionized water, and mix evenly. In this solution, until the swelling is balanced, take it out, and irradiate it with weak ultraviolet light at 100 watts for 5 hours to obtain a high-strength double-network hydrogel. The hydrogel can absorb water 10 times its own weight, has a tensile strength of 0.35 MPa, a breaking elongation of 200%, a compressive strength of 12 MPa, and a compressive deformation rate of over 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com