Method for reducing 4H-SiC intrinsic deep energy level defects

A deep-level and defect technology, applied in the field of microelectronic materials and devices, can solve the problems of lack of consideration of temperature and surface protection, affecting the quality of 4H-SiC single crystal, and unable to effectively reduce deep-level defects, so as to reduce damage. , the effect of reducing the precipitation of Si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

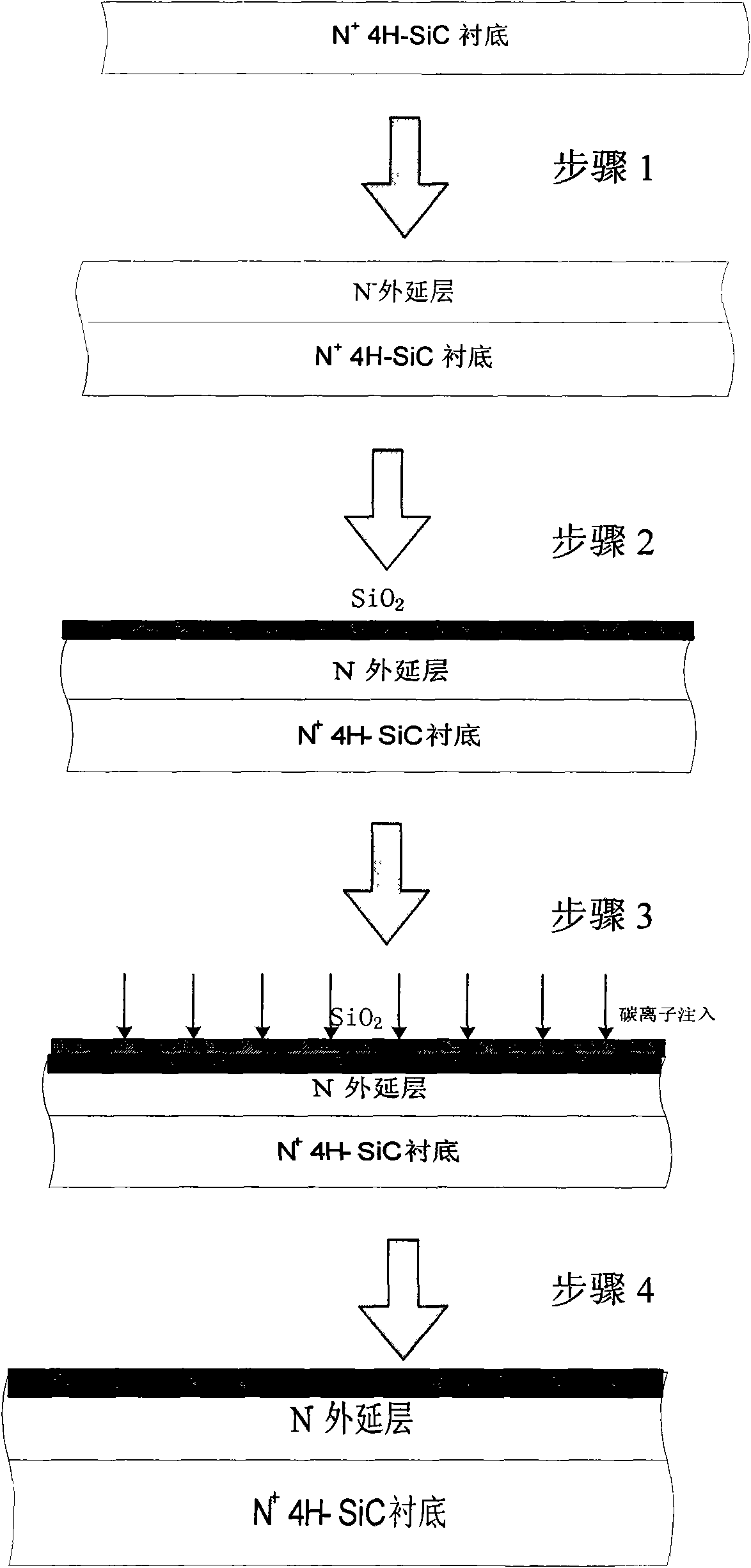

[0026] refer to figure 1 , the present invention comprises the following steps:

[0027] Step 1, pretreating the used 4H-SiC material.

[0028] Using 4H-SiC material produced by CREE company, its doping level is 10 18 cm -3 . First, passivate the surface of the 4H-SiC substrate with molten KOH, the etching temperature is 210°C, and the etching time is 15s; then, the passivated wafer is cleaned with acetone, methanol, and deionized water in sequence Clean; finally, use RCA standard cleaning process to remove the oxide layer on the surface of the sample.

[0029] Step 2, grow N on the substrate - epitaxial layer.

[0030] Homogeneous N was grown by CVD on pretreated substrates - type epitaxial layer, the epitaxial layer doping is 1.1×10 15 cm -3 , with a thickness of 10 ± 0.1 μm.

[0031] In step 3, the ion implantation barrier layer is fabricated by a deposition method.

[0032] After the epitaxial wafer is cleaned by RCA standard, 100nm SiO2 is formed on the front o...

Embodiment 2

[0040] refer to figure 1 , the present invention comprises the following steps:

[0041] Step 1, pretreating the used 4H-SiC material.

[0042] Using 4H-SiC material produced by CREE company, its doping level is 10 18 cm -3 . First, passivate the surface of the 4H-SiC substrate with molten KOH, the etching temperature is 210°C, and the etching time is 15s; then, the passivated wafer is cleaned with acetone, methanol, and deionized water in sequence Clean; finally, use RCA standard cleaning process to remove the oxide layer on the surface of the sample.

[0043] Step 2, grow N on the substrate - epitaxial layer.

[0044] Homogeneous N was grown by CVD on pretreated substrates - type epitaxial layer, the epitaxial layer doping is 1.1×10 15cm -3 , with a thickness of 10 ± 0.1 μm.

[0045] In step 3, the ion implantation barrier layer is fabricated by a deposition method.

[0046] After the epitaxial wafer is cleaned by RCA standard, 200nm SiO2 is formed on the front of...

Embodiment 3

[0054] refer to figure 1 , the present invention comprises the following steps:

[0055] Step 1, pretreating the used 4H-SiC material.

[0056] Using 4H-SiC material produced by CREE company, its doping level is 10 18 cm -3 . First, passivate the surface of the 4H-SiC substrate with molten KOH, the etching temperature is 210°C, and the etching time is 15s; then, the passivated wafer is cleaned with acetone, methanol, and deionized water in sequence Clean; finally, use RCA standard cleaning process to remove the oxide layer on the surface of the sample.

[0057] Step 2, grow N on the substrate - epitaxial layer.

[0058] Homogeneous N was grown by CVD on pretreated substrates - type epitaxial layer, the epitaxial layer doping is 1.1×10 15 cm -3 , with a thickness of 10 ± 0.1 μm.

[0059] In step 3, the ion implantation barrier layer is fabricated by a deposition method.

[0060] After the epitaxial wafer is cleaned by RCA standard, 100nm SiO2 is formed on the front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com