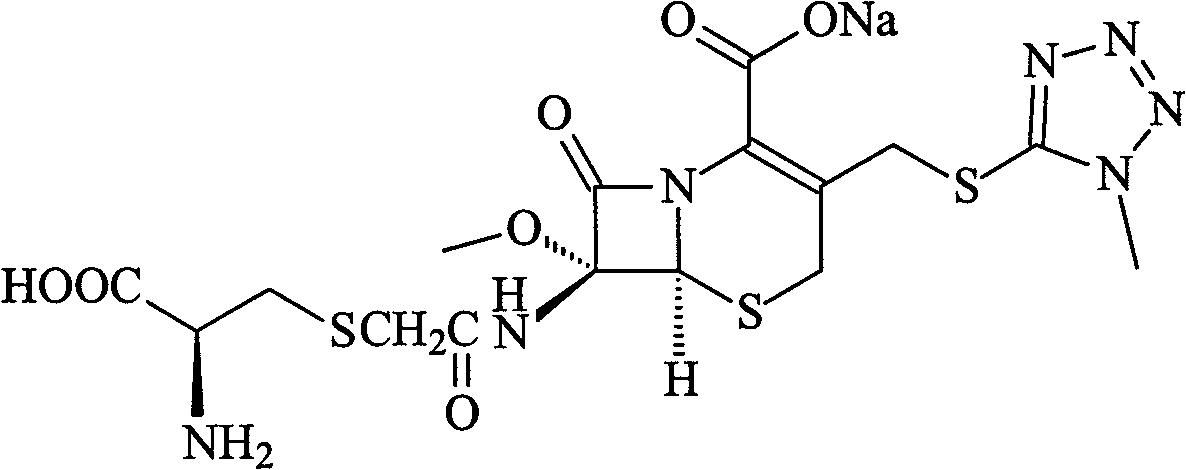

Cefminox sodium liposome preparation

A technology of cefminox sodium lipid and cefminox sodium, applied in the field of medicine, can solve problems such as poor stability, and achieve the effects of improving stability, stable product quality and reducing drug side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

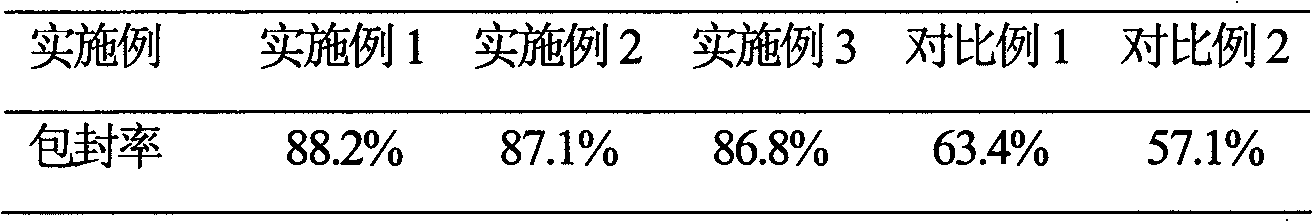

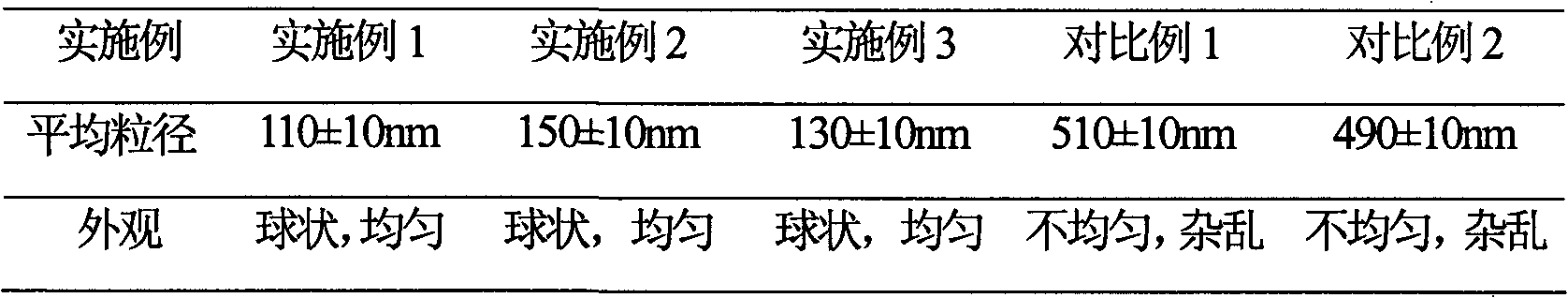

Embodiment 1

[0030] The preparation of embodiment 1 cefminox sodium liposome

[0031] Prescription: Cefminox Sodium 100g

[0032] Soy Lecithin 100g

[0033] Cholesterol 400g

[0034] Vitamin E 10g

[0035] Sorbitol 400g

[0036] Trehalose 100g

[0037] Preparation Process

[0038] (1) 100g soybean lecithin, 400g cholesterol and 10g vitamin E are dissolved in 1000ml chloroform and n-butanol volume ratio in the mixed solvent of 1: 5, mix homogeneously, remove chloroform and n-butanol under reduced pressure on the rotary film evaporator, Prepare phospholipid film;

[0039] (2) Add pH 5.6 citrate buffer solution 1000ml, shake, stir to make phospholipid film fully hydrated, high-speed homogeneous emulsification, microporous membrane filtration, make blank liposome suspension;

[0040] (3) Dissolve 100g of cefminox sodium in 500ml of water, filter through a microporous membrane, add the filtrate to the blank liposome suspension, incubate at 50°C and stir for ...

Embodiment 2

[0042] The preparation of embodiment 2 cefminox sodium liposomes

[0043] Prescription: Cefminox Sodium 50g

[0044] Soy Lecithin 400g

[0045] Cholesterol 100g

[0046] tert-Butyl p-Hydroxyanisole 50g

[0047] Sorbitol 240g

[0048] Trehalose 60g

[0049] Preparation Process

[0050] (1) Dissolve 400g of soybean lecithin, 100g of cholesterol and 50g of tert-butyl p-hydroxyanisole in 1000ml of chloroform and n-butanol in a mixed solvent with a volume ratio of 1:5, mix well, and remove under reduced pressure on a rotary thin film evaporator Chloroform and n-butanol to prepare phospholipid film;

[0051] (2) Add 1000ml of acetate buffer solution with a pH value of 5.4, shake, stir to make the phospholipid film fully hydrated, high-speed homogeneous emulsification, and microporous membrane filtration to obtain a blank liposome suspension;

[0052](3) Dissolve 50g of cefminox sodium in 300ml of water, filter through a microporous membrane, add ...

Embodiment 3

[0054] The preparation of embodiment 3 cefminox sodium liposomes

[0055] Prescription: Cefminox Sodium 150g

[0056] Soy Lecithin 500g

[0057] Cholesterol 200g

[0058] Ascorbyl Palmitate 80g

[0059] Sorbitol 640g

[0060] Trehalose 160g

[0061] Preparation Process

[0062] (1) 500g soybean lecithin, 200g cholesterol and 80g ascorbyl palmitate are dissolved in 1500ml chloroform and n-butanol in a mixed solvent with a volume ratio of 1:5, mix well, and remove chloroform and n-butyl under reduced pressure on a rotary thin film evaporator Alcohol, make phospholipid film;

[0063] (2) Add 1200ml of pH value 5.3 phosphate buffer solution, shake, stir to make phospholipid membrane fully hydrated, high-speed homogeneous emulsification, microporous membrane filtration, make blank liposome suspension;

[0064] (3) Dissolve 150g cefminox sodium in 1000ml water, filter through a microporous membrane, add the filtrate to the blank liposome suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com