Preparation method of doped modified lithium iron phosphate

A lithium iron phosphate modification technology, which is applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve the problems such as the difficulty in the industrial preparation of lithium iron phosphate as a positive electrode material for lithium ions, and achieve improved high-rate performance, growth inhibition, and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

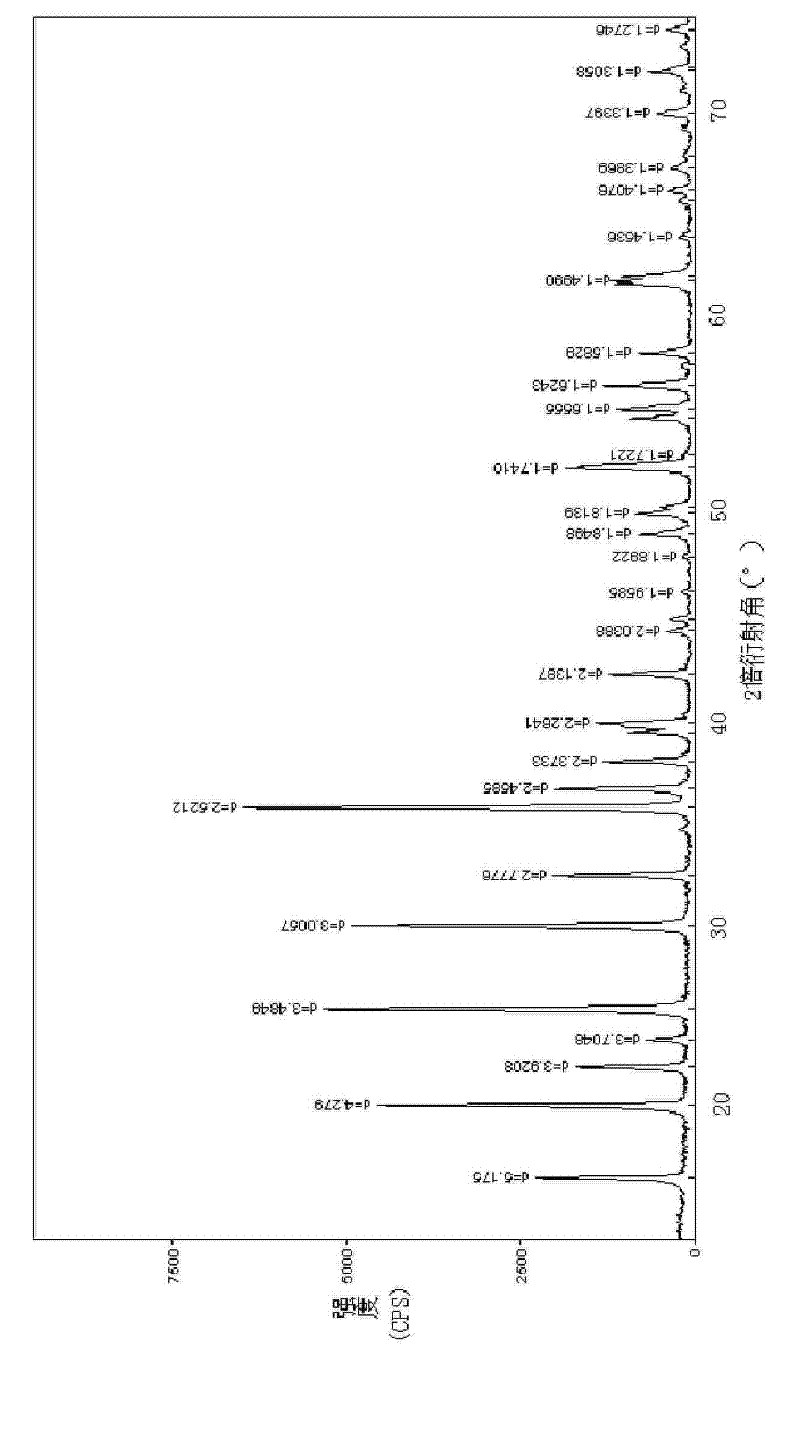

Image

Examples

Embodiment 1

[0032] First, mix 74.27g of lithium hydroxide monohydrate LiOH H2O, 133.22g of ferric oxide Fe2O3, 197.47g of ammonium dihydrogen phosphate, 40g of white sugar and 3.42g of magnesium oxide MgO into a sand mill at a concentration of 0.5 Wt% polyethylene glycol aqueous solution, the ratio of ball material to water is 2:1:2, high-speed ball milling (600rpm) for 5 hours; then the slurry after mixed sand milling is dried in a 100°C oven, then pulverized and processed Put it into a nitrogen atmosphere sintering furnace, under the protection of 10 liters / minute of high-purity nitrogen, raise the temperature to 750°C at a rate of 3°C / min, keep it warm for 6 hours, and then cool down to room temperature. After the sintered material is pulverized by a pulverizer, it is classified on a jet mill to obtain lithium iron phosphate with uniform particles. The carbon content in the material was measured to be 4.5%.

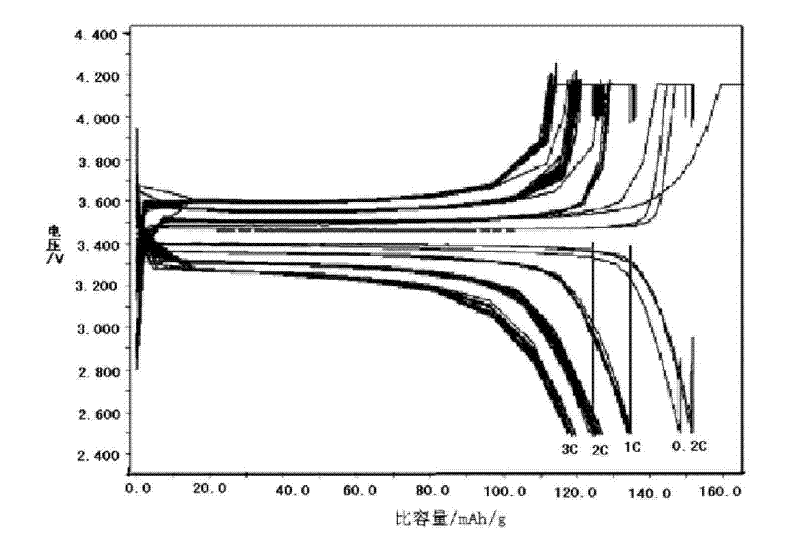

[0033] The measured tap density of the material is 1.3g / cm 3 .

[0034] Th...

Embodiment 2

[0042] First, 74.27g lithium hydroxide monohydrate LiOH·H 2 O, 133.22g ferric oxide Fe 2 o 3 , 197.47g ammonium dihydrogen phosphate, 20g carbon black and 6.55g trimanganese tetraoxide Mn 3 o 4 Mix and put into a sand mill, add AEO9 aqueous solution with a concentration of 1.0wt.%, add 1% ethanol anhydrous alcohol, and perform high-speed ball milling (600rpm) in a ball mill for 8 hours. Dry the mixed and sand-milled slurry in a 100°C oven, then pulverize it and put it into a nitrogen atmosphere sintering furnace. Under the protection of 10 liters / min of high-purity nitrogen, the temperature is raised to 750°C at a rate of 3.5°C / min. ℃ for 4 hours, and then cooled to room temperature. After the sintered material is crushed with a crusher, it is classified on a jet mill to obtain lithium iron phosphate with uniform particles.

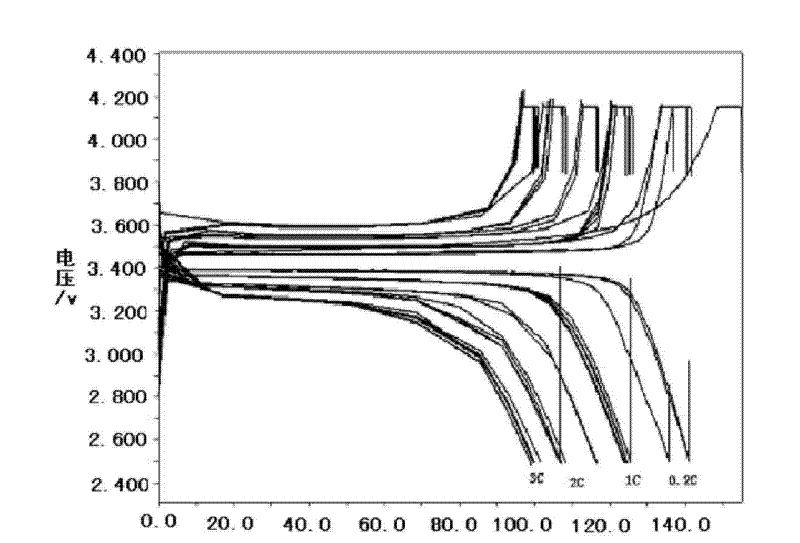

[0043] The material obtained in Example 2 was sent to a lithium-ion battery factory to be prepared as an electrode sheet and assembled into a batter...

Embodiment 3

[0045] First, 74.27g lithium hydroxide monohydrate LiOH·H 2 O, 133.22g ferric oxide Fe 2 o 3 , 197.47g ammonium dihydrogen phosphate, 40g white granulated sugar and 6.37g cobalt oxide CoO are mixed and put into a sand mill, adding a concentration of 0.8wt.% AEO9 aqueous solution, and high-speed ball milling (700rpm) in a ball mill for 4 hours. Dry the mixed and sand-milled slurry in a 100°C oven, then pulverize it and put it into a nitrogen atmosphere sintering furnace. Under the protection of 10 liters / min of high-purity nitrogen, the temperature is raised to 750 at a rate of 5°C / min. ℃ for 6 hours, and then cooled to room temperature. After the sintered material is crushed with a pulverizer, it is classified on a jet mill to obtain lithium iron phosphate with uniform particles.

[0046] The carbon content of the active material was measured to be 5.12%. A simulated button battery was prepared according to the method of Example 1. After the battery was assembled, the rever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com