Undoped red organic electroluminescent material and preparation method and applications thereof

A reaction and compound technology, applied in the field of organic electroluminescence, can solve problems such as energy matching, phase separation and carrier transport imbalance, increase of non-radiative inactivation process, weakening of fluorescence quantum efficiency, etc. Transport ability, reduced dipole-dipole interaction, effects of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

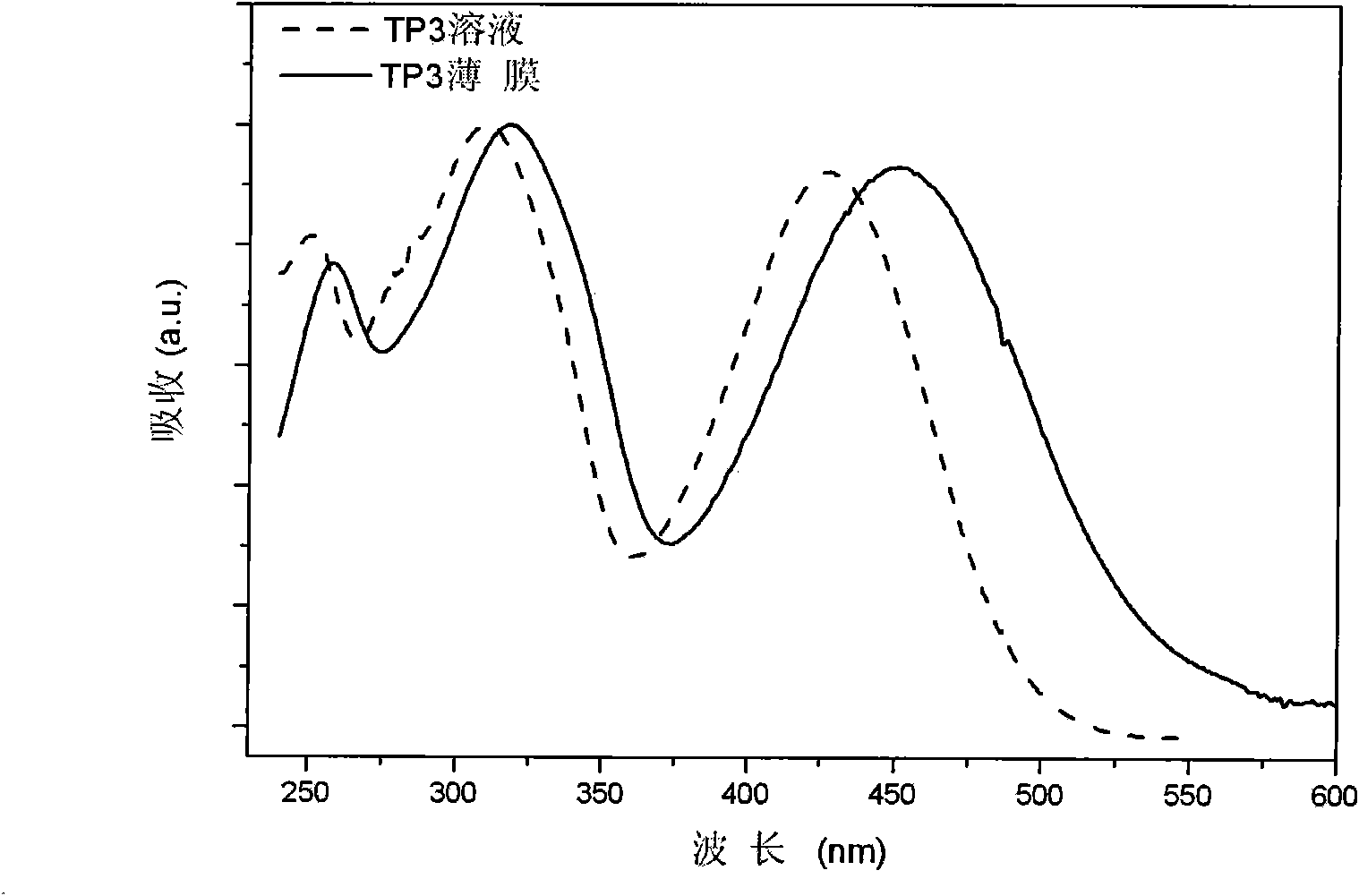

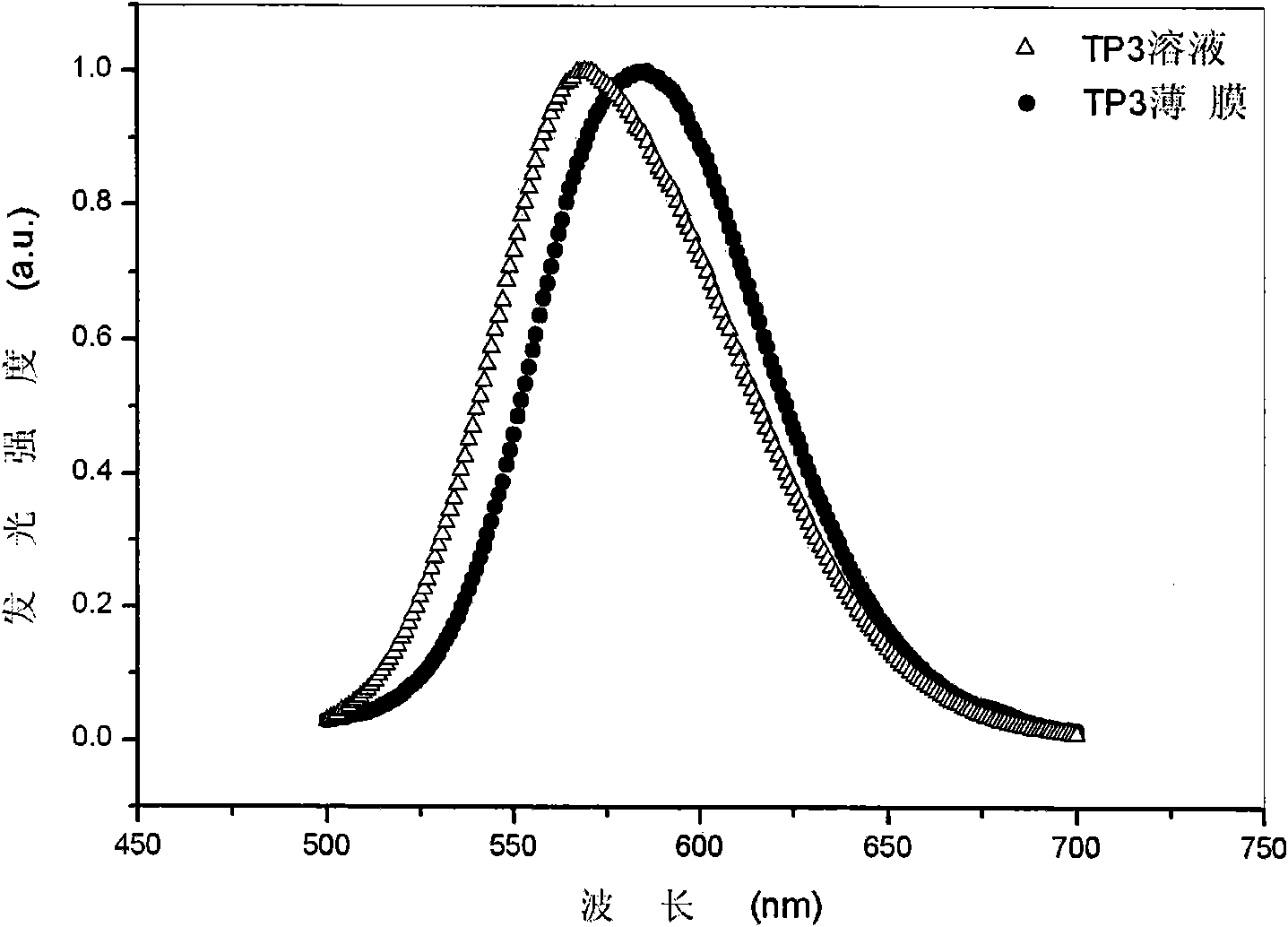

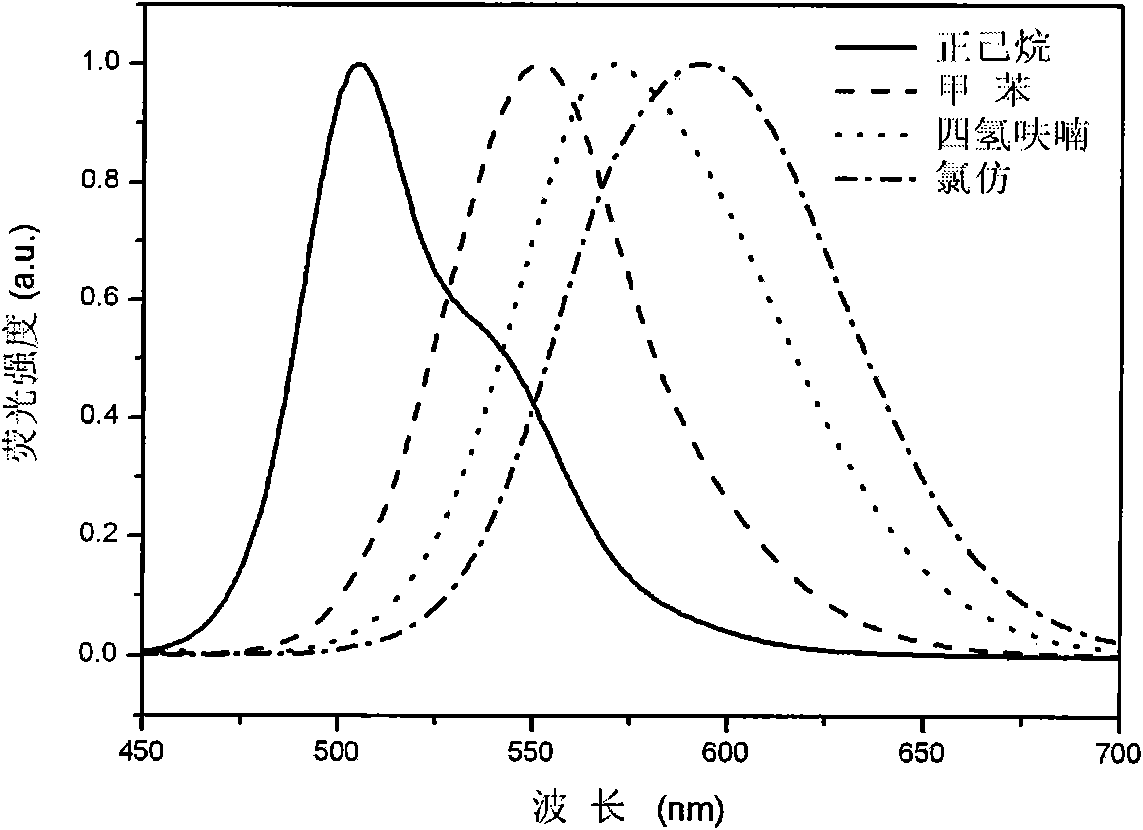

[0049] Example 1 Preparation and properties of undoped red organic electroluminescent material TP3

[0050] 1. Preparation of 2,4,6-trimethyl-1,3,5-s-triazine (Compound 1)

[0051] Mix 24.6g of acetonitrile (0.6mol) and 27.6g of absolute ethanol (0.2mol) in the three-necked flask, pass hydrogen chloride gas at room temperature until 0.6mol of hydrogen chloride is absorbed, that is, the reaction solution has a weight gain of 14.3g. Stir at room temperature for 16 hours. After completion of the reaction, the crude product was filtered off and dried. After drying, it was added to a vigorously stirred mixture of 50 mL of dichloromethane, 125 mL of water and potassium carbonate (0.6 mol). The organic layer was separated after stirring for 10 minutes. The aqueous solution was extracted twice with 50 mL of dichloromethane (25 mL each). The organic phases were combined and placed in the refrigerator to dry over anhydrous potassium carbonate overnight. Most of the solvent was remo...

Embodiment 2

[0071] Example 2 Preparation of single-layer undoped red electroluminescent device

[0072] This embodiment prepares the undoped red electroluminescent device according to the following method:

[0073] a) Cleaning ITO (indium tin oxide) glass: ultrasonically clean the ITO glass with deionized water, acetone, and ethanol for 15 minutes each, and then treat in a plasma cleaner for 2 minutes;

[0074] b) Spin-coating PEDOT:PSS as a hole injection layer on anodic ITO glass at 4000 rpm, annealed at 200 °C for 5 min in air, and then annealed at 200 °C for 15 min in nitrogen. The thickness is 28nm;

[0075] c) spin-coating the light-emitting layer TP3 on the PEDOT:PSS layer, the concentration of TP3 is 12 mg / mL, the rotation speed is 2000 rpm, and the thickness is 80 nm;

[0076] d) Vacuum evaporation of LiF on the light-emitting layer TP3, rate Thickness 0.5nm;

[0077] e) Cathode Al was vacuum-evaporated on top of LiF with a thickness of 120 nm.

[0078] The structure of the...

Embodiment 3

[0079] Example 3 Preparation of double-layer undoped red electroluminescent device

[0080] This embodiment prepares the undoped red electroluminescent device according to the following method:

[0081] a) Cleaning the ITO glass: ultrasonically clean the ITO glass with deionized water, acetone and ethanol for 15 minutes each, and then treat it in a plasma cleaner for 2 minutes;

[0082] b) Spin-coating PEDOT:PSS as a hole injection layer on anodic ITO glass at 4000 rpm, annealed at 200 °C for 5 min in air, and then annealed at 200 °C for 15 min in nitrogen. The thickness is 28nm;

[0083] c) Spin-coat the light-emitting layer TP3 on the PEDOT:PSS layer, the concentration of TP3 is 9 mg / mL, the rotation speed is 2000 rpm, and the thickness is 40 nm. ;

[0084] d) Vacuum evaporation of electron transport layer Alq on the light-emitting layer TP3 3 (8-hydroxyquinoline aluminum), rate Thickness 30nm;

[0085] e) Alq in the electron transport layer 3 LiF was deposited on to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com