Artificial nerve graft prepared by electrostatic spinning and preparation method and special device thereof

An electrospinning process and artificial nerve technology are applied in the field of artificial nerve grafts and their preparation, which can solve the problems of difficult matching of tissue structure and size, limited nerve sources, and long-term denervation in the transplant donor area, and achieve good use effects. , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

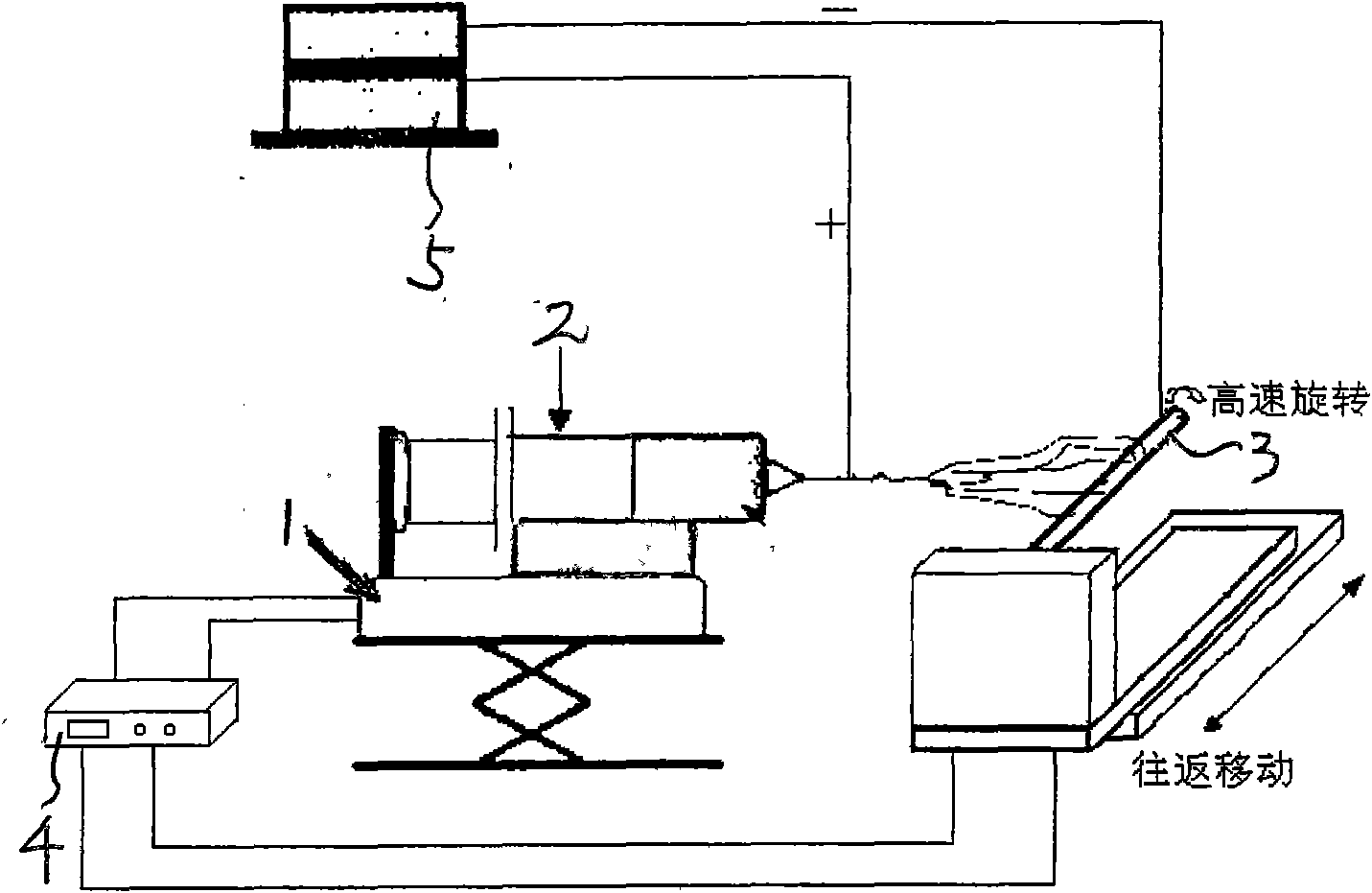

[0021] Heat the silk in a weak alkali solution (0.1-10% sodium carbonate or 0.1-10% potassium carbonate) at 50-100°C, then wash the treated fibers with distilled water to obtain silk fibroin fibers, and part of the silk prepared above Silk fibroin fiber is dissolved in the ternary system of calcium chloride, ethanol and water at 25-80°C (eg 25°C, 50°C, 80°C) (the molar ratio is calcium chloride: ethanol: water = 1: 2:8), the dissolution time is 0.5 to 6 hours (for example 0.5, 3, and 6 hours), the dissolved mixed solution is packed into a cellulose membrane bag, and dialyzed with distilled water. Then inject the dialyzed silk fibroin solution into a flat mold, and obtain a silk fibroin film after drying, and dissolve the obtained silk fibroin film with formic acid to form a spinning stock solution with a solution concentration of 13% (mass concentration), and then use electrospinning The process uses the above-mentioned special device for preparing the artificial nerve graft p...

Embodiment 2

[0023] Chitosan is dissolved with weak acid, and weak acid is acetic acid (or phosphoric acid, citric acid, lactic acid), and concentration is 2~15% (example 2%, 8%, 15%), adds the collagen solution of certain concentration (example 5%, 25%, 50%) to prepare a spinning stock solution with a concentration (mass concentration) of 10%, and then use the electrospinning process to carry out molding processing with the above-mentioned special device for preparing the artificial nerve graft prepared by electrospinning, and the micrometering pump After metering, the spinning stock solution enters the solution injector, sprays the spinning solution on the collecting roller that rotates and moves back and forth to form nanofibers, and forms a tube on the collecting roller. The injection speed is 0.2ml / h, the distance between the end of the solution injector and the collecting roller is 8-11cm, the translation speed of the collecting roller is 2m / hour, and the rotating speed is 90 rpm. Th...

Embodiment 3

[0025] Dissolve polyglycolic acid (PGA), polylactic acid (PLA), or glycolic acid lactic acid copolymer (PLGA, 50 / 50) in chloroform into a spinning solution with a solution concentration of 10-20% (mass concentration), and then use electrospinning The silk process uses the above-mentioned special device for preparing the artificial nerve graft prepared by electrospinning to carry out molding processing. The spinning stock solution is metered by a micro metering pump and then enters the solution injector, and the spinning solution is sprayed on the collecting roller that rotates and moves back and forth. , forming nanofibers, and forming a tube on the collection roller, the voltage of the high-voltage electrostatic generator during the above-mentioned forming process is 20-30KV, the solution injection speed is 0.2ml / h, and the distance between the end of the solution injector and the collection roller is 7-11cm, The translational speed of the collecting roller is 2m / hour, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com