Antireflection film used in all-angle and wide wavelength range and preparation method thereof

A wide-wavelength, full-angle technology, applied in the field of anti-reflection film and its preparation, can solve the problems of high cost, complex process, inability to use polycrystalline silicon and amorphous silicon solar cells, etc., and achieve the effect of increasing mechanical properties and firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Mix metal alkoxide, water, ethanol and hydrochloric acid with a molar ratio of 1:1:10:0.01, stir, carry out hydrolysis polymerization, and age for 7 days, wherein the metal alkoxide is ethyl orthosilicate;

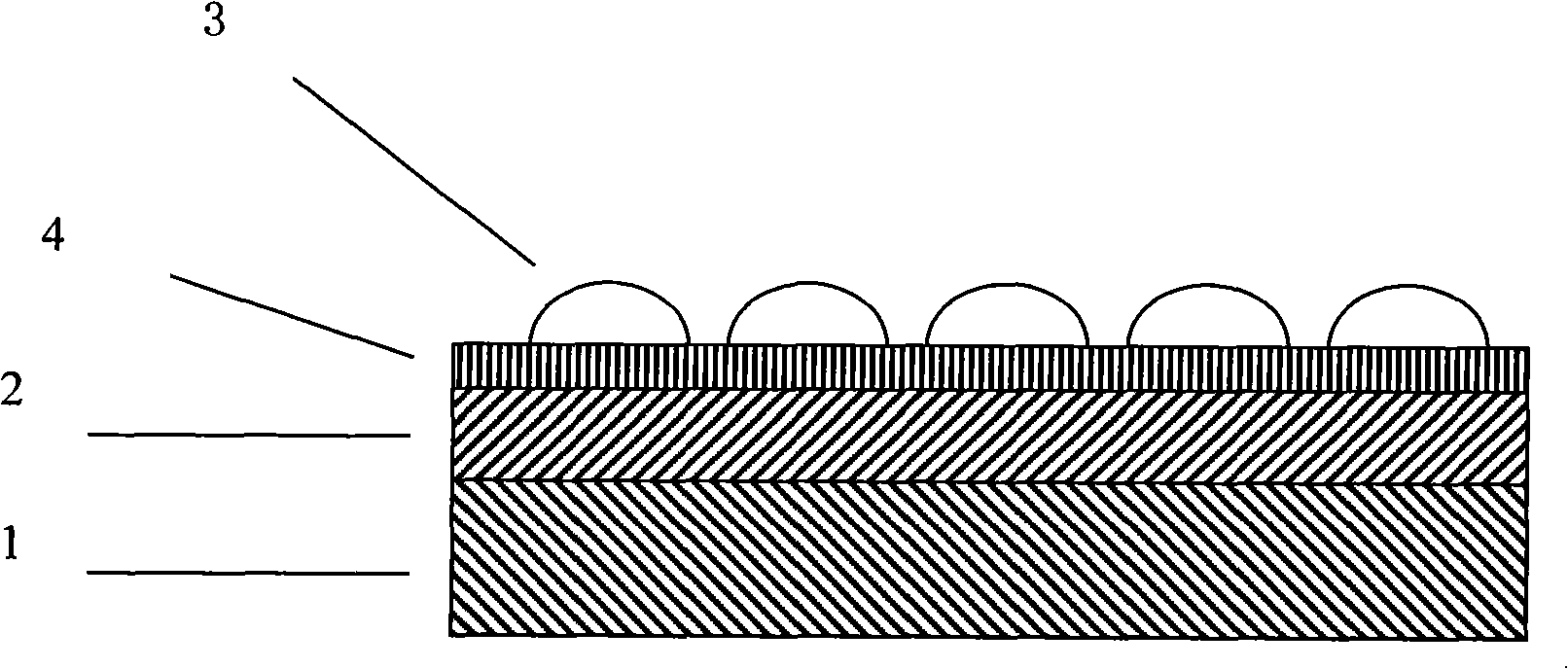

[0022] 2) Coating the aged solution on the surface of the optical glass substrate 1 by a pulling method at a pulling rate of 50 mm / min, annealing at a temperature of 200° C. after the film is formed, to obtain the first sol-gel cross-linked Linked film layer 2;

[0023] 3) The substrate 1 coated with the first sol-gel cross-linked film layer 2 is immersed in an aqueous solution of polyelectrolyte polydiallyldimethylammonium chloride for 5 minutes to make the first sol-gel cross-linked film layer 2 The surface is uniformly positively charged. After taking it out, rinse it with deionized water to remove excess polyelectrolyte polydiallyl dimethyl ammonium chloride. The molecular weight of polyelectrolyte polydiallyl dimethyl ammonium chloride is 20~ 350,000, the c...

Embodiment 2

[0029] 1) Mix metal alkoxide, water, ethanol and hydrochloric acid with a molar ratio of 1:4:40:0.01, stir, carry out hydrolysis polymerization, and age for 5 days, wherein the metal alkoxide is ethyl orthosilicate and titanic acid Butyl ester and mixed solution, the molar ratio is 1: 1;

[0030] 2) Coating the aged solution on the surface of the silicon single crystal substrate 1 with a pulling method at a pulling rate of 400 mm / min, and annealing at 500°C after the film is formed to obtain the first sol-gel Cross-linked film layer 2;

[0031] 3) The substrate 1 coated with the first sol-gel cross-linked film layer 2 is immersed in an aqueous solution of polyelectrolyte polydiallyldimethylammonium chloride for 5 minutes to make the first sol-gel cross-linked film layer 2 The surface is uniformly positively charged. After taking it out, rinse it with deionized water to remove excess polyelectrolyte polydiallyl dimethyl ammonium chloride. The molecular weight of polyelectrolyt...

Embodiment 3

[0037] 1) Mix metal alkoxide, water, ethanol and hydrochloric acid with a molar ratio of 1:2:37:0.01, stir, carry out hydrolysis polymerization, and age for 7 days, wherein the metal alkoxide is ethyl orthosilicate;

[0038] 2) Coating the aged solution on the surface of the optical glass substrate 1 by a pulling method at a pulling rate of 300 mm / min, and annealing at a temperature of 500° C. after the film is formed, to obtain the first sol-gel cross-linking method. Linked film layer 2;

[0039] 3) The substrate 1 coated with the first sol-gel cross-linked film layer 2 is immersed in an aqueous solution of polyelectrolyte polydiallyldimethylammonium chloride for 5 minutes to make the first sol-gel cross-linked film layer 2 The surface is uniformly positively charged. After taking it out, rinse it with deionized water to remove excess polyelectrolyte polydiallyl dimethyl ammonium chloride. The molecular weight of polyelectrolyte polydiallyl dimethyl ammonium chloride is 20~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com