Method for preparing nanocrystal ternary titanium dioxide porous electrode by auxiliary crystallization in electrophoretic deposition high-voltage electric field

A titanium dioxide, high-voltage electric field technology, applied in electrophoretic plating, electrical components, circuits, etc., can solve problems such as unfavorable light scattering, cannot improve the utilization rate of incident light, etc., achieves good repeatability, facilitates large-area production, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

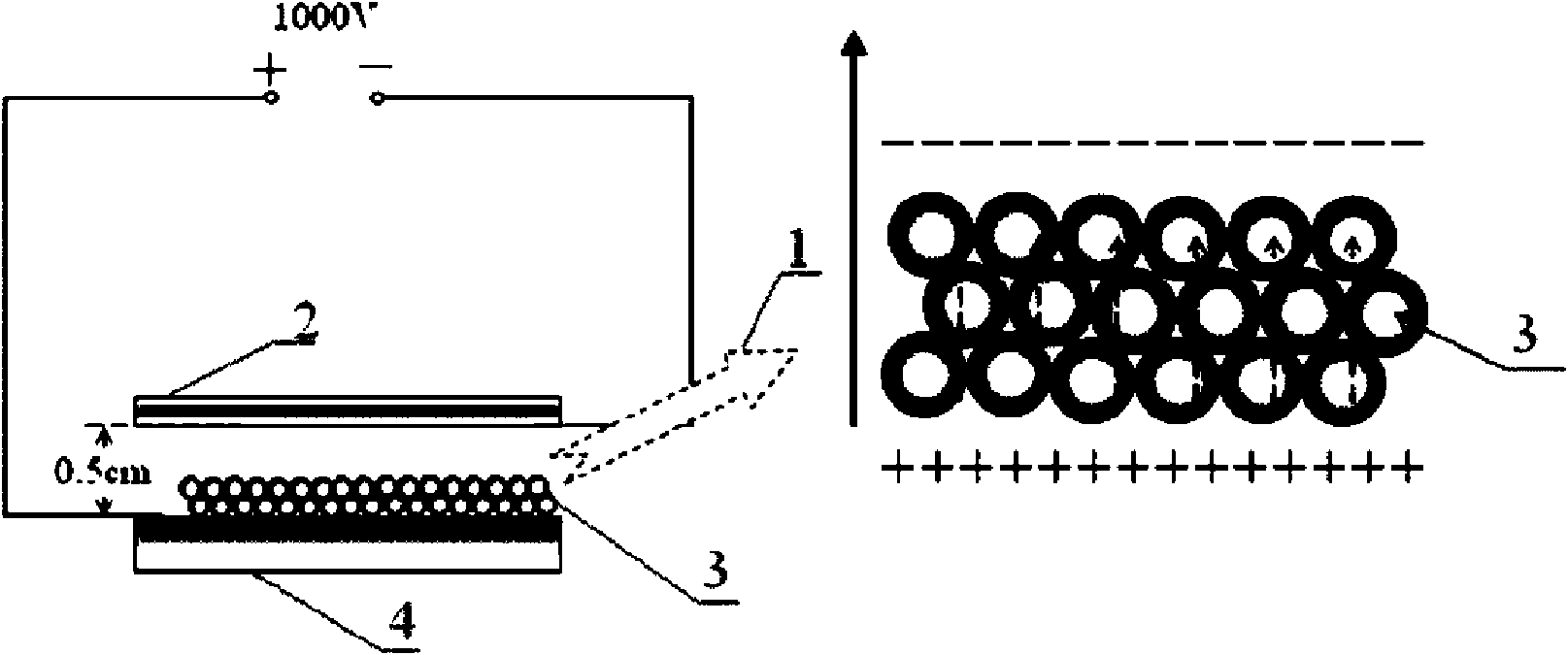

[0012] Specific Embodiment 1: In this embodiment, the method for preparing nanocrystalline ternary titanium dioxide porous electrode by electrophoretic deposition with high-voltage electric field-assisted crystallization is as follows: 1. Hydrolyze tetrabutyl titanate under ultrasonic conditions to synthesize mesoporous titanium dioxide sol; 2. Use hydrothermal Prepare titanium dioxide colloid G2 by sol-gel method, prepare titanium dioxide colloid G3 by sol-gel method; three, mix P25 titanium dioxide and acetic anhydride and stir for 0.5 hour, add titanium dioxide colloid G3 and maleic acid mass concentration and be 50% acetone solution, then in Under the condition of ultrasonic frequency of 45kHz, sonicate for 15 minutes to 30 minutes, then add titanium dioxide colloid G2 and polyethylene glycol ethanol solution with a mass concentration of polyethylene glycol of 2% to 6%, stir for 0.5 hour to 1 hour, and then add Water ethanol, ultrasonic 15 minutes~30 minutes under the condi...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of step one mesoporous titania sol is as follows: 1. Mix concentrated hydrochloric acid, secondary deionized water and absolute ethanol to prepare solution A, concentrated hydrochloric acid The volume ratio with the secondary deionized water is 1~9:30, and the volume ratio between the secondary deionized water and absolute ethanol is 0.2~1:1; 2. Tetrabutyl titanate, absolute ethanol and acetylacetone Mix to prepare solution B, the volume ratio of tetrabutyl titanate to absolute ethanol is 4-9:6, the volume ratio of absolute ethanol to acetylacetone is 8-36:3; A is added dropwise into solution B with an ultrasonic frequency of 45kHz. After the addition, ultrasonication is performed for 1 to 2 hours under the condition of an ultrasonic frequency of 45kHz to obtain a light yellow transparent mesoporous titanium dioxide sol; the mass of concentrated hydr...

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the method for preparing titanium dioxide colloid G2 by hydrothermal method in step two is as follows: tetrabutyl titanate, acetic anhydride and absolute ethanol are mixed to obtain a mixed solution, The mass ratio of tetrabutyl titanate to acetic anhydride is 4~8:3, and the mass ratio of the volume of absolute ethanol to acetic anhydride is 10~25:3; : a volume ratio of 1 to obtain an aqueous ethanol solution; three, the aqueous ethanol solution is added dropwise to the mixed solution obtained in step one, and after the dropwise addition is completed for 0.5 hour to 1 hour, a light yellow transparent sol is obtained; four, the light yellow transparent The sol was heated in an autoclave at a temperature of 160°C to 200°C for 12 to 20 hours to obtain a milky white precipitate, then dissolved the milky white precipitate with absolute ethanol, and ultrasonicated at an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com