Hydrophilous porous phenolic resin as well as preparation method and application thereof

A kind of resin and phenolic resin technology, applied in the field of hydrophilic porous phenolic resin and its preparation, can solve the problems of no regeneration method, unfavorable industrial utilization and promotion, high adsorption cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Embodiment 1: the preparation of porous catechol formaldehyde resin

[0103] Add 2.20g of catechol, 2ml of formaldehyde (37wt%) and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to dissolve it completely, put the above solution into a reaction kettle, keep it at 100°C for 5 hours, and mash the obtained gel , add 50g of ethanol and stir for 6 hours, filter, wash with ethanol, and grind the filter cake when the ethanol content is about 80% after natural drying, and dry under a nitrogen atmosphere at 120°C to obtain a light black powder. The pore volume of the obtained material is 2.4 cm 3 g -1 , the specific surface area is 1008m 2 g -1 .

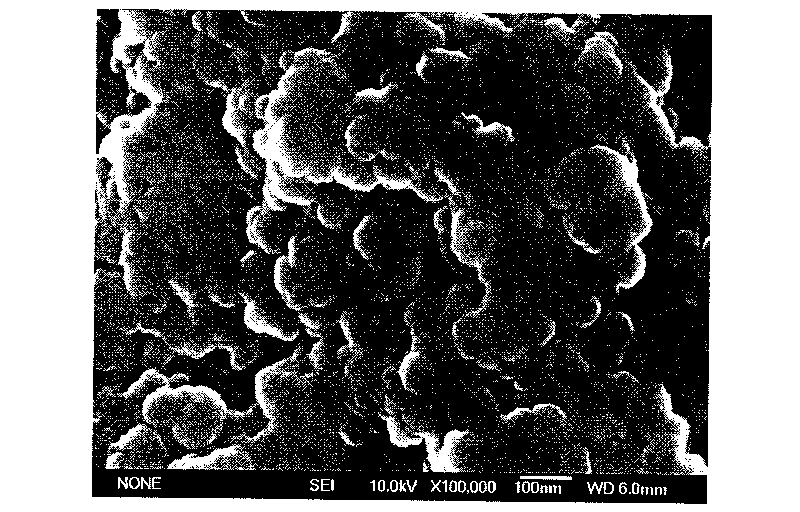

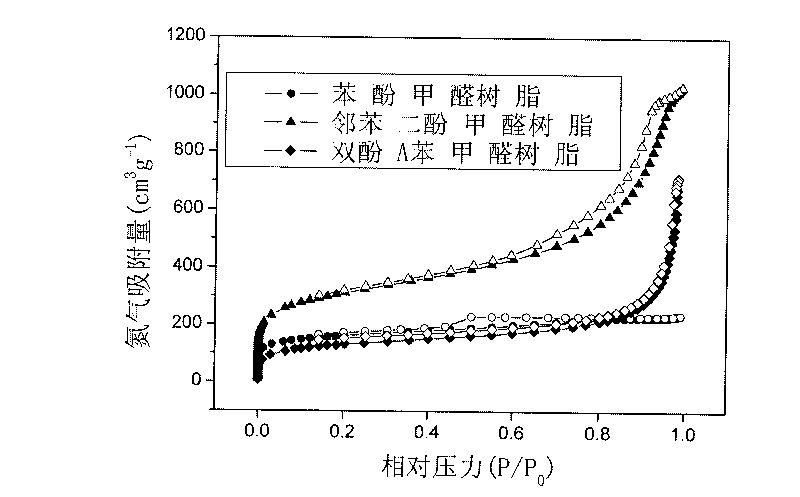

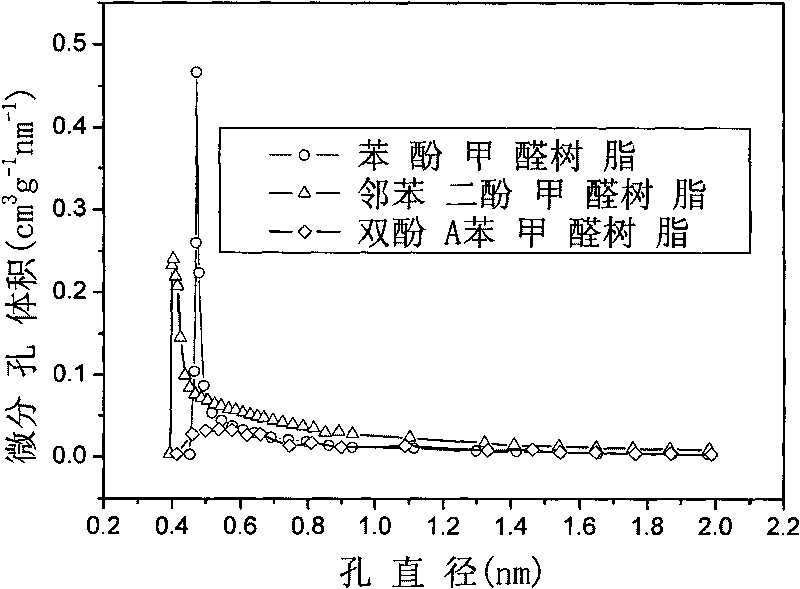

[0104] The scanning electron micrograph of the porous catechol formaldehyde resin that makes in the present embodiment is as figure 1 as shown, figure 1 The macroporous structure of the material and its particle morphology are visually displayed in . The nitrogen adsorption-desorption isotherm of the resin is ...

Embodiment 2

[0111] Embodiment 2: porous catechol acetaldehyde resin (alkali catalysis)

[0112] Add 2.20g of catechol, 3ml of acetaldehyde (37wt%) and 0.5g of NaOH into 10ml of ethanol together, stir to make it dissolve completely, put the above solution into a reaction kettle, and keep it warm at 100°C for 10 hours, and the resulting gel is pounded Grind, add 50g 5wt% hydrochloric acid ethanol solution and stir for 6 hours, filter, wash with ethanol, dry the filter cake naturally until the ethanol content is about 40%, grind it, and dry under a nitrogen atmosphere at 120°C to obtain a light black powder. The pore volume of the material is 1.4cm 3 g -1 , the specific surface area is 807m 2 g -1 . The nitrogen adsorption-desorption isotherm of the resin is as follows figure 2 as shown, figure 2 It shows that the material has high specific surface area, pore volume and hierarchical pore structure, in which phenol-formaldehyde resin is mainly microporous. The pore size distribution ...

Embodiment 3

[0114] Embodiment 3: porous catechol acetaldehyde resin (acid catalysis)

[0115] Add 2.20g of catechol, 3ml of acetaldehyde (37wt%) and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to make it dissolve completely, put the above solution into a reaction kettle, and keep it warm at 100°C for 10 hours. Crushed, added 50g ethanol and stirred for 6 hours, filtered, washed with ethanol, and the filter cake was naturally dried until the ethanol content was about 40%, and it was ground, and dried under a nitrogen atmosphere at 120°C to obtain a light black powder. The pore volume of the obtained material was 1.6cm 3 g -1 , the specific surface area is 879m 2 g -1 . The infrared spectrum of the resin material is shown in Figure 4 as shown, Figure 4 It shows that the material is a phenolic resin obtained by dehydration condensation of phenol and aldehyde.

[0116] Gained material is measured by the method for embodiment 1 and its gold, the adsorption capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com