Method for preparing glutaric acid from dimethyl glutarate

A technology of dimethyl glutarate and glutaric acid, which is applied in the preparation of carboxylate/lactone, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of incomplete process , There are no problems such as public technology, complex process route, etc., to achieve the effect of improving catalytic yield and reaction rate, convenient source and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

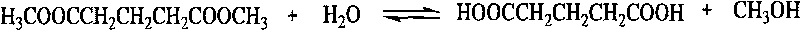

Image

Examples

Embodiment 1

[0028] In a 150mL single-necked round-bottom flask, add the activated strong acid styrene-based cation exchange resin catalyst, dimethyl glutarate and deionized water to form a mixed system, so that the amount of the catalyst in the mixed system is 170g / L, pentadiene The volume ratio of dimethyl ester to deionized water is 12:1, a fractionation device is connected above the flask, heated to 130°C, and the reaction time is 2h.

[0029] The glutaric acid yield was measured to be 88.84%.

Embodiment 2

[0031] As in Example 1, but the amount of catalyst is 130g / L. The glutaric acid yield was measured to be 87.14%.

Embodiment 3

[0033] As in Example 1, but the amount of catalyst is 200g / L. The glutaric acid yield was measured to be 88.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com