Method for producing volatile fatty acid by using sludge as substrate

A volatile fatty acid and substrate technology, applied in the field of fatty acids, can solve problems such as long production cycle, achieve the effects of reducing pollution, reducing investment and operating costs, and increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Determination of volatile fatty acids: The qualitative and quantitative analysis of various VFAs is carried out by gas chromatography. Before the detection, the samples are first centrifuged at 15,000 rpm for 5 minutes, and then the supernatant is filtered with a 0.45 μm filter membrane. Gas chromatograph (GC9560) analysis conditions: chromatographic column: SE-30 capillary column; carrier gas: nitrogen; pre-column pressure: 0.06MPa; injector: 170°C; column temperature: 140°C; detector temperature: 200°C; Injection volume: 5 μL. The detection conditions of standard samples of volatile fatty acids such as acetic acid, propionic acid, butyric acid and valeric acid are the same as above.

Embodiment 2

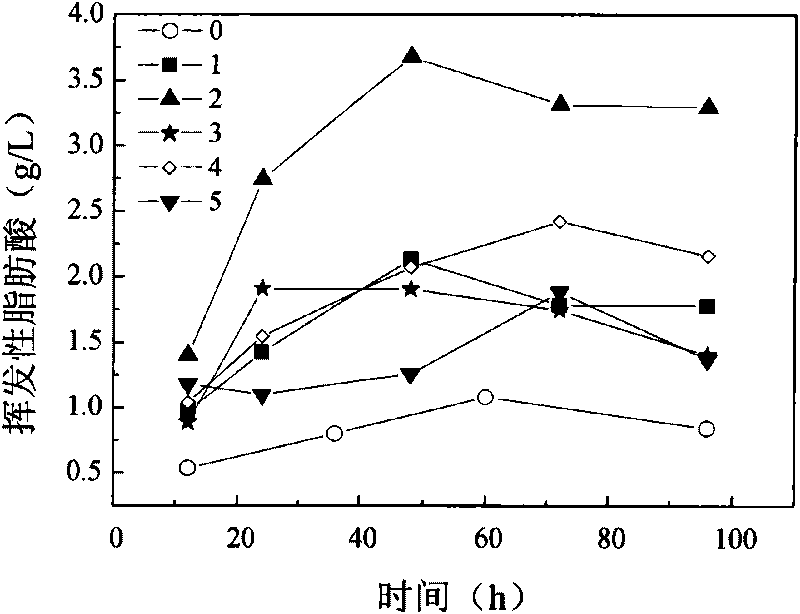

[0020] Put 1L MLSS (mixed liquid suspended solids concentration) of 41g / L sludge as substrate sludge into a 1L Erlenmeyer flask, add 12mL of anaerobic sludge with a concentration of 45g / L as inoculum, and then Under magnetic stirring. After 60 hours of reaction, volatile fatty acids with a concentration of 1.08 g / L were obtained. The result is as figure 1 Shown (0. Blank control: no pretreatment).

Embodiment 3

[0022] Add 7g sodium hydroxide to 1L MLSS of 41g / L sludge, and treat it for 30min under the condition of magnetic stirring at room temperature. Use hydrochloric acid solution to adjust the pH value to 7.5, put it as substrate sludge in a 1L conical flask, add 12mL of anaerobic sludge with a concentration of 45g / L as inoculum, and stir magnetically at room temperature. After 48 hours of reaction, volatile fatty acids with a concentration of 2.13 g / L were obtained. The result is as figure 1 Shown (1. Temperature: room temperature, NaOH: 7g / L, time: 30min).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com