Method for preparing flexible air purifying material by low temperature in situ synthesis

An air purification material, low-temperature in-situ technology, applied in textiles and papermaking, deodorization, fiber treatment, etc., can solve the problems of flexible substrates such as easy photooxidative degradation, complicated manufacturing, and serious agglomeration, so as to avoid the decline of agglomeration efficiency, Good air purification effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

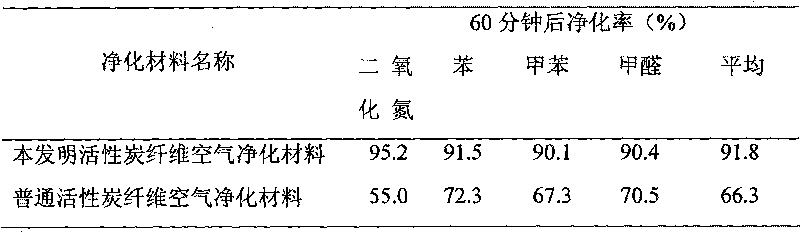

Embodiment 1

[0029] (1) Surface pretreatment of flexible substrates

[0030] Clean the activated carbon fiber surface ultrasonically with acetone solution for 30 minutes, and dry it at room temperature for 12 hours; dip the pretreated activated carbon fiber in benzoyl chloride and anionic softener for two dips and two rolls (residue rate 70%), and then dry it at 60 ° C. Pre-bake for 3 minutes, bake at 120°C for 1 minute, wash with hot water at 70°C for 3 times after cooling, and dry at 80°C for 2 minutes.

[0031] (2) Anti-photooxidation protective finishing of flexible substrates

[0032] The modified activated carbon fiber padding cotton fiber anti-oxidation finishing solution LZQ was taken out after 30 minutes, pre-baked at 70°C, and then heated to 130°C for 2 minutes.

[0033] (3) Preparation of low temperature precursor

[0034] Under an inert environment, slowly add 0.02mol titanium tetraisopropoxide to 30mL isopropanol under stirring, add 0.01mol triethylamine as a stabilizer to t...

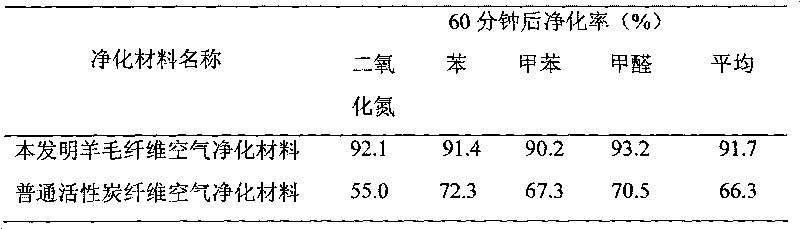

Embodiment 2

[0042] (1) Surface pretreatment of flexible substrates

[0043] Ultrasonic cleaning of the wool fiber surface with acetone solution for 40 minutes, and drying at room temperature for 14 hours; the pre-treated wool fiber was dipped and rolled twice in polyvinyl alcohol and anionic softener solution (reduction rate 75%), and then heated at 63 ° C Pre-bake at low temperature for 4 minutes, bake at 135°C for 1.5 minutes, wash with hot water at 75°C for 3 times after cooling, and dry at 83°C for 3 minutes.

[0044] (2) Anti-photooxidation protective finishing of flexible substrates

[0045] The modified wool fiber padding cotton fiber anti-oxidation finishing solution LZQ was taken out after 40 minutes, pre-baked at 75°C, and then heated to 140°C for 3 minutes.

[0046] (3) Preparation of low temperature precursor

[0047] Under an inert environment, slowly add 0.07mol titanium tetraisopropoxide to 40mL isobutanol under stirring, add 0.02mol triethanolamine as a stabilizer to the...

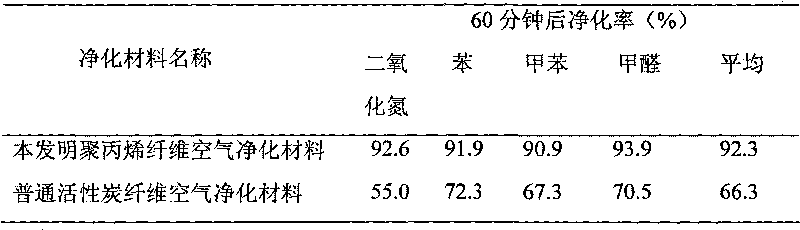

Embodiment 3

[0055] (1) Surface pretreatment of flexible substrates

[0056] Use acetone solution to ultrasonically clean the surface of polypropylene fiber for 50 minutes, and dry it at room temperature for 16 hours; dip the pretreated polypropylene fiber twice in sodium carbonate and anionic softener solution (passing rate 80%), and then dry it at 65 Pre-bake at ℃ for 5 minutes, bake at 150℃ for 2 minutes, wash with hot water at 80℃ for 4 times after cooling, and dry at 85℃ for 4 minutes.

[0057] (2) Anti-photooxidation protective finishing of flexible substrates

[0058] The modified polypropylene fiber padding cotton fiber anti-oxidation finishing solution LZQ was taken out after 50 minutes, pre-baked at 80°C, and then heated to 150°C for 4 minutes.

[0059] (3) Preparation of low temperature precursor

[0060] Under an inert environment, slowly add 0.15mol titanium tetraisopropoxide to 50ml isopentyl glycol under stirring, add 0.03mol triethanolamine as a stabilizer to the mixture,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com