Gel injection molding method for high-gravity alloy

A technology of gel injection molding and high specific gravity, which is applied in the field of high specific gravity alloy products with high solid content and complex shape by gel injection molding with excellent performance, and can solve the difficulties in preparation, complex shapes, and development limitations of parts, etc. problems, to achieve the effect of simple process, reduced production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

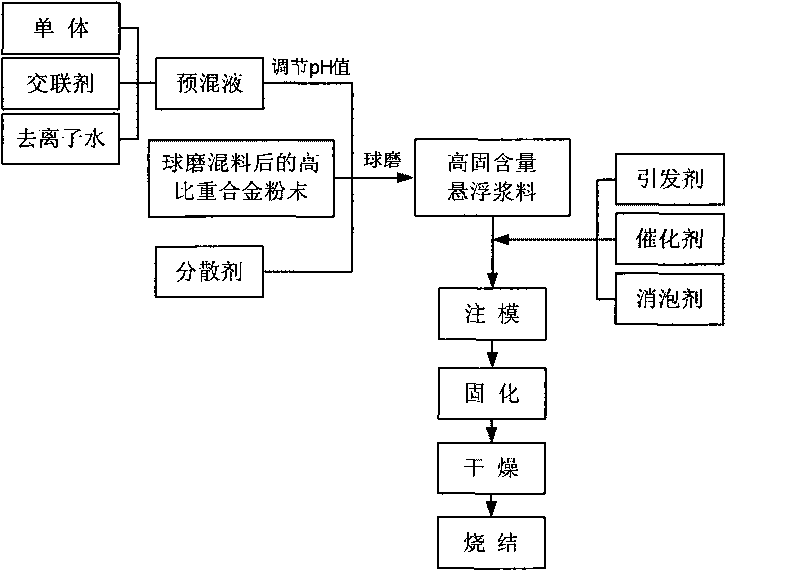

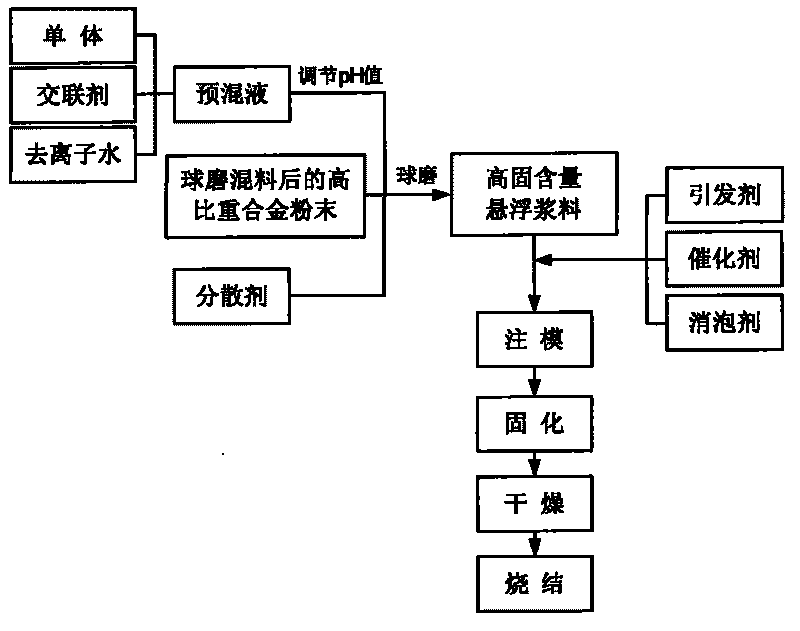

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Superheavy alloy W-Ni-Cu based gel injection molding

[0023] 1. According to the superheavy alloy W-Ni-Cu formula, respectively mix -500 mesh tungsten powder, nickel powder, copper powder and molybdenum powder (W 85-98%, Ni1.35-10%, Cu 0.6-3%, Mo 0.05 ~2%) after ball milling and mixing for 6 hours, weigh 1.7 kg of mixed alloy powder for use. .

[0024] 2. Dissolve 24.7g monomeric acrylamide and 0.27g crosslinking agent N,N′-methylenebisacrylamide in 115ml deionized water, add the mixed alloy powder in step 1, and stir evenly;

[0025] 3. Measure 0.7ml of dispersant oleic acid and 0.2ml of self-made dispersant into the solution in the second step, stir evenly, and make a slurry with moderate fluidity after ball milling for 7.5 hours, and degas the slurry for 25 minutes under vacuum ;

[0026] 4. Measure 0.8ml of catalyst N,N,N',N'-tetramethylethylenediamine and 1ml of initiator ammonium persulfate, add them to the slurry in step 3, and stir evenly.

[002...

Embodiment 2

[0030] Example 2: Gel injection molding of superheavy alloy W-Ni-Fe system weight ring

[0031] 1. According to the superheavy alloy W-Ni-Fe system formula, 650 mesh tungsten powder, nickel powder and iron powder (W 85-98%, Ni1.35-10%, Fe 0.6-2.5%, Mo 0.05-2.5%) After ball milling and mixing for 10 hours, 3.4 kg of mixed alloy powder was weighed for use.

[0032] 2. Dissolve 45.4g of monomeric acrylamide and 0.55g of crosslinking agent N,N'-methylenebisacrylamide in 276ml of deionized water, add the mixed alloy powder in step 1, and stir evenly;

[0033] 3. Measure 2.9ml of dispersant oleic acid into the solution in the second step, stir evenly, and make a slurry with moderate fluidity after ball milling for 7 hours, and degas the slurry for 35 minutes under vacuum to remove residual air bubbles;

[0034] 4. Measure 2ml of catalyst N, N, N', N'-tetramethylethylenediamine and 3.2ml of initiator ammonium persulfate (to ensure sufficient injection molding time), add to the slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com