Preparation method for microemulsion solvent thermosynthesis monodisperse titanium dioxide nanocrystalline

A titanium dioxide and microemulsion technology, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve problems such as poor dispersion, and achieve the effects of good crystallinity, good dispersion and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

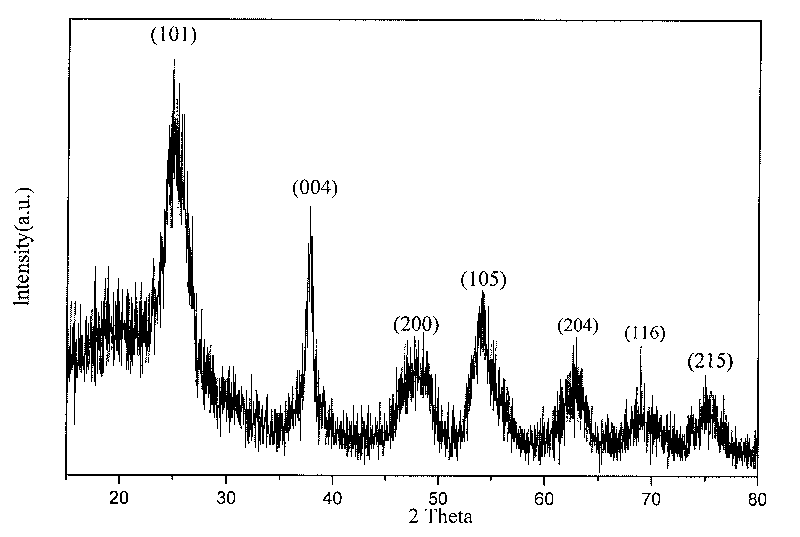

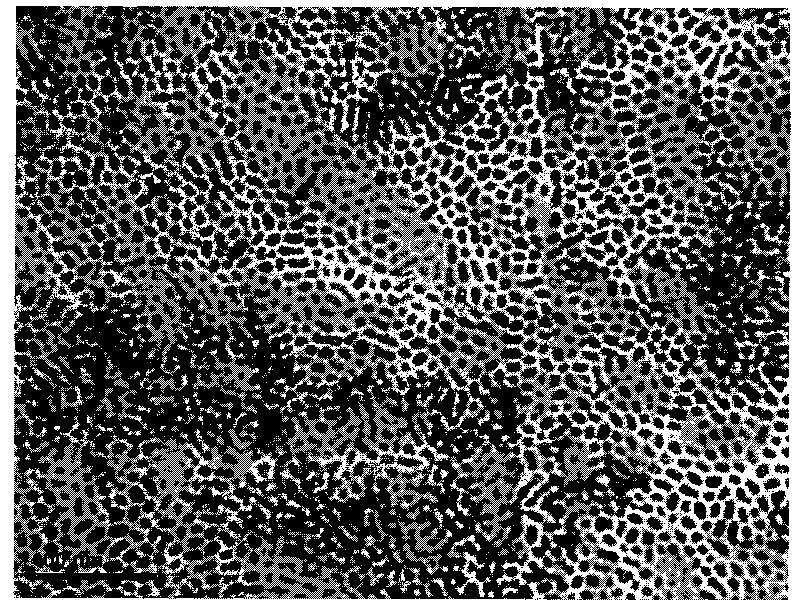

[0031] Accurately measure 10mL of oleic acid and place it in a round-bottomed flask, then add 2ml of butyl carbonate to it, stir evenly at room temperature for 1h to prepare a mixed solution, measure 2ml of deionized water and add it dropwise to the above mixed solution, and stir for 1h . Then the body solution before the reaction is moved into a 180ml stainless steel reaction kettle, and after being sealed, the whole reaction kettle is moved into an oven, the reaction temperature is 300°C, and the time is 0.5h. Centrifuge and wash twice with n-hexane, put the washed product into an oven, and dry it at room temperature for 24 hours to obtain the product for preservation. figure 1 is the X-ray diffraction pattern of the product, which shows that the obtained product is a typical anatase structure. figure 2 It is a transmission electron microscope photograph of the product, and it can be seen that the obtained titanium dioxide nanocrystals are rod and spherical, with a diamete...

Embodiment 2

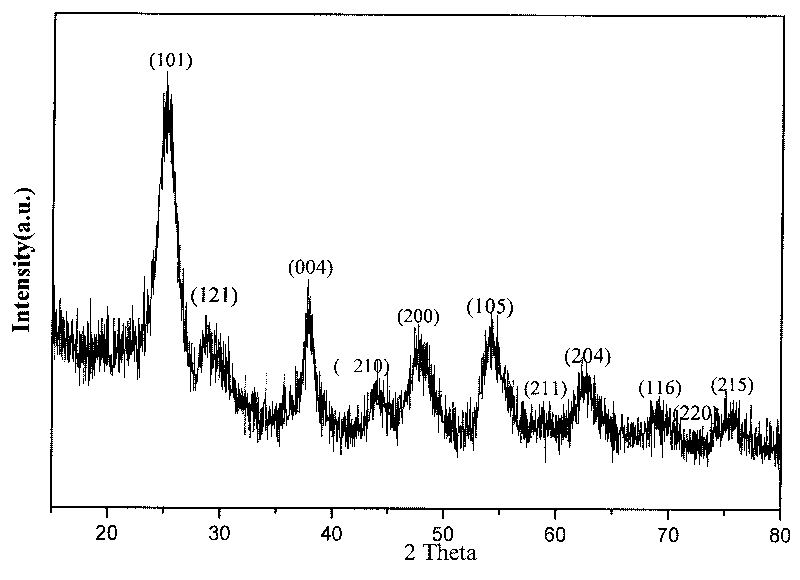

[0033] Accurately measure 15mL of oleic acid and place it in a round-bottomed flask, then add 5ml of butyl carbonate into it, stir evenly at room temperature for 1h to prepare a mixed solution, measure 4ml of deionized water and add it dropwise to the above mixed solution, and stir for 1h . Then the body solution before the reaction is moved into a 180ml stainless steel reaction kettle, and after being sealed, the whole reaction kettle is moved into an oven. The reaction temperature is 300°C and the time is 1h. Centrifuge and wash twice with alkanes, put the washed product into an oven, and dry it at room temperature for 24 hours to obtain the product for preservation. image 3 is the X-ray diffraction pattern of the product, which shows that the obtained product is a typical titanium oxide anatase structure, and the diffraction peaks are obviously broadened. Figure 4 It is a transmission electron microscope photograph of the product, and it can be seen that the obtained nan...

Embodiment 3

[0035] Accurately measure 20mL of oleic acid and place it in a round-bottomed flask, then add 5ml of butyl carbonate to it, stir evenly at room temperature for 1h to prepare a mixed solution, measure 6ml of deionized water and add it dropwise to the above mixed solution, and stir for 1h . Then the body solution before the reaction is moved into a 180ml stainless steel reaction kettle, and after sealing, the whole reaction kettle is moved into an oven. The reaction temperature is 300°C, and the time is 2h. Centrifuge and wash twice with alkanes, put the washed product into an oven, and dry it at room temperature for 24 hours to obtain the product for preservation. Figure 5 is the X-ray diffraction pattern of the product, which shows that the obtained product is a typical titanium oxide anatase structure, and the diffraction peaks are obviously broadened. Figure 6 It is a transmission electron microscope photograph of the product, and it can be seen that the obtained titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com