Phosphotungstic acid modified catalyst, preparation method and application in acrolein preparation thereof

A technology of phosphotungstic acid and catalyst, which is applied in the field of phosphotungstic acid modified catalyst, preparation and its application in the production of acrolein, which can solve the problems of continuous production of catalyst, large amount of catalyst coke adhesion, low conversion rate of glycerin, etc. Problems, to achieve the effect of stable production, renewable use of corrosive, not easy to slime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

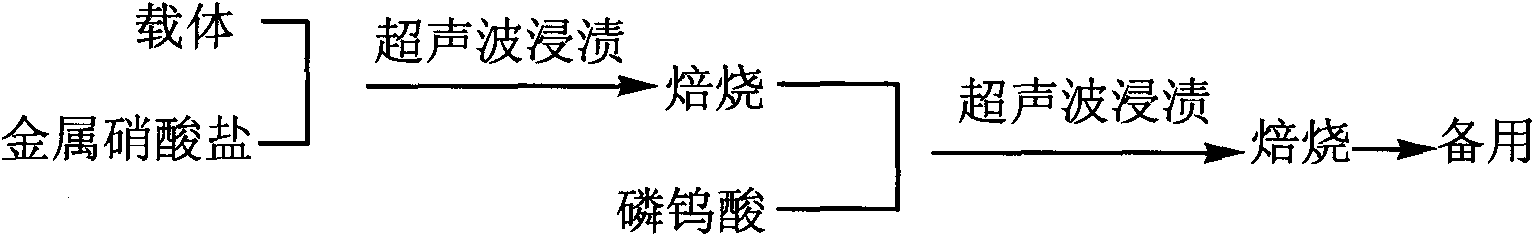

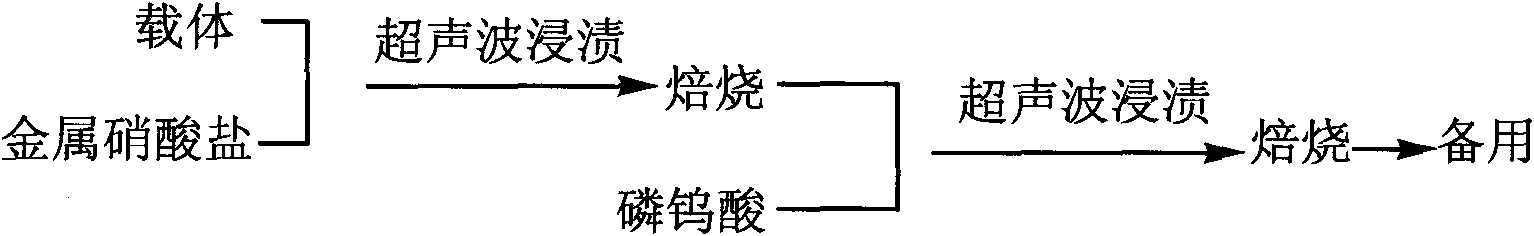

[0031] Example 1 CuO-Al 2 o 3 / H 3 PW 12 o 40 catalyst

[0032] According to CuO, Al 2 o 3 and H 3 PW 12 o 40 The mass ratio of the three is 1:69:30 to prepare CuO-Al 2 o 3 / H 3 PW 12 o 40 catalyst.

[0033] The specific method is:

[0034] Step 1: CuO-modified Al 2 o 3 Preparation of vector

[0035] Prepared by isometric impregnation. First, weigh 18-30 mesh Al 2 o 3 10.0g. Then weigh Cu(NO 3 ) 2 ·6H 2 O 1.36g, dissolved in 12ml of distilled water, prepared as an aqueous solution. The final Al to be weighed 2 o 3 Pour 10.0g into the prepared solution, ultrasonically oscillate for 2 hours, impregnate for 24 hours, put it into a horse boiling furnace, and roast at 300°C to prepare CuO-Al 2 o 3 ,spare.

[0036] The second step: CuO-Al 2 o 3 / H 3 PW 12 o 40 Catalyst preparation

[0037] The same volume dipping method is used to prepare. First, weigh the CuO-modified Al 2 o 3 Carrier 10.0 g. Then, weigh 4.29g of phosphotungstic acid, dissolv...

Embodiment 2

[0039] Example 2 ZnO-Al 2 o 3 / H 3 PW 12 o 40 catalyst

[0040] According to ZnO, Al 2 o 3 and H 3 PW 12 o 40 The mass ratio of the three is 2:68:30 to prepare ZnO-Al 2 o 3 / H 3 PW 12 o 40 catalyst.

[0041] The specific method is:

[0042] The first step: ZnO modified Al 2 o 3 Preparation of vector

[0043] Prepared by isometric impregnation. First weigh 18-30 mesh Al 2 o 3 10.0g. Then weigh Zn(NO 3 ) 2 ·6H 2 O 1.08g, dissolved in 12ml of distilled water, prepared as an aqueous solution. Finally, pour 10.0 g of weighed alumina into the prepared aqueous solution, ultrasonically oscillate for 3 hours, soak for 24 hours, put it into a horse boiling furnace, and roast at 400 ° C to obtain ZnO-Al 2 o 3 ,spare.

[0044] The second step: ZnO-Al 2 o 3 / H 3 PW 12 o 40 Catalyst preparation

[0045] The same volume dipping method is used to prepare. First, weigh the ZnO-modified Al 2 o 3 Carrier 10.0 g. Then weigh 4.29g of phosphotungstic acid, diss...

Embodiment 3

[0047] Example 3La 2 o 3 -Al 2 o 3 / H 3 PW 12 o 40 catalyst

[0048] According to La 2 o 3 、Al 2 o 3 and H 3 PW 12 o 40 The mass ratio of the three is 2:68:30 to prepare La 2 o 3 -Al 2 o 3 / H 3 PW 12 o 40 catalyst. The specific method is:

[0049] The first step: La 2 o 3 Modified Al 2 o 3 Preparation of vector

[0050] Prepared by isometric impregnation. First weigh 18-30 mesh Al 2 o 3 10.0g. Then weigh La(NO 3 ) 3 ·6H 2 O 0.78g, dissolved in 12ml of distilled water, prepared as an aqueous solution. The final Al to be weighed 2 o 3 Pour 10.0 g into the prepared aqueous solution, oscillate ultrasonically for 4 hours, soak for 24 hours, put it in a horse boiling furnace, and roast at 450°C to obtain La 2 o 3 -Al 2 o 3 ,spare.

[0051] The second step: La 2 o 3 -Al 2 o 3 / H 3 PW 12 o 40 Catalyst preparation

[0052] The same volume dipping method is used to prepare. First, weigh the scripture La 2 o 3 Modified Al 2 o 3 Carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com