Construction method of medical titanium alloy implant surface growth factor delivery system

A technology of surface growth and construction method, used in medical science, prosthesis and other directions, can solve the problems of unsatisfactory sintering strength, difficult to guarantee bonding strength, etc., achieve strong and reliable adhesion, meet strong adhesion, coating preparation simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. However, the present invention is not limited to the following examples.

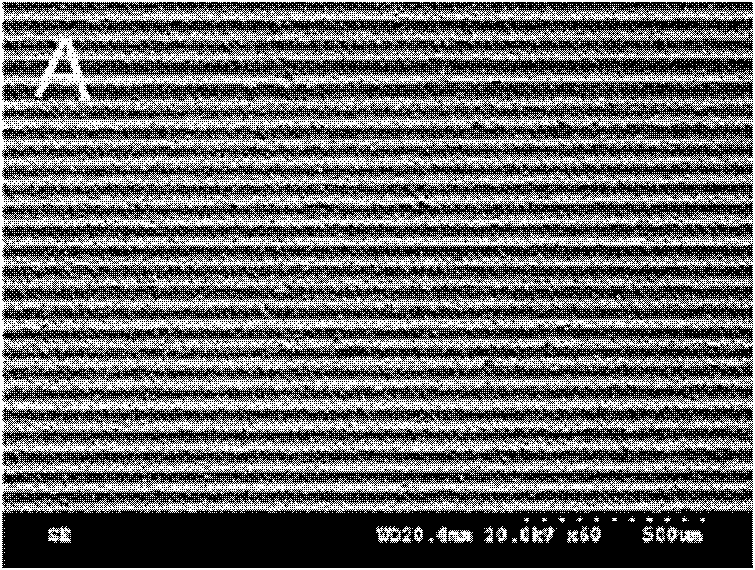

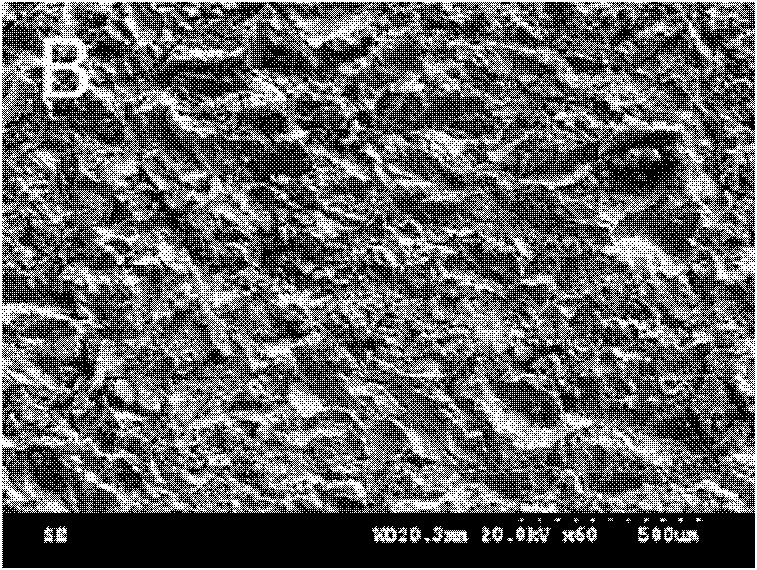

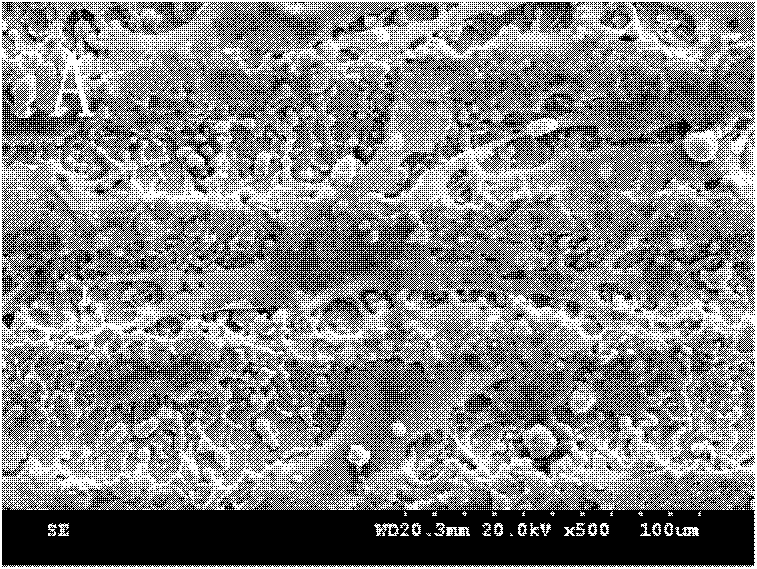

[0011] According to previous studies, the surface of microgrooves and ridges is more suitable for the adhesion and growth of osteoblasts than the smooth surface and irregular frosted surface (see Figure 1, 2), and its preparation process is simple, the quality is easy to control, and it is more suitable for industrial production. Related research results have been published (Jun Fu, Zheng Guo, Yunyu Hu, Yongquan Zhang, Yulin Hao, Shujun Li. Effect of surface micro-topography of titanium material on the behaviors of rabbit osteoblast in vitro. Applied Surface Science. 2008; 255: 286 -289). Therefore, this application adopts the surface of micro-grooves and ridges to replace the previous sintered surface of titanium beads to overcome the problems of insufficient sintering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com