Face-centred cubic structure Ti3Si nano particles and preparation method thereof

A nanoparticle and face-centered cubic technology is applied in the field of face-centered cubic Ti3Si nanoparticles and their preparation, which can solve the problems of long production cycle, environmental pollution, complex process, etc., and achieves low energy consumption, wide application prospects and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

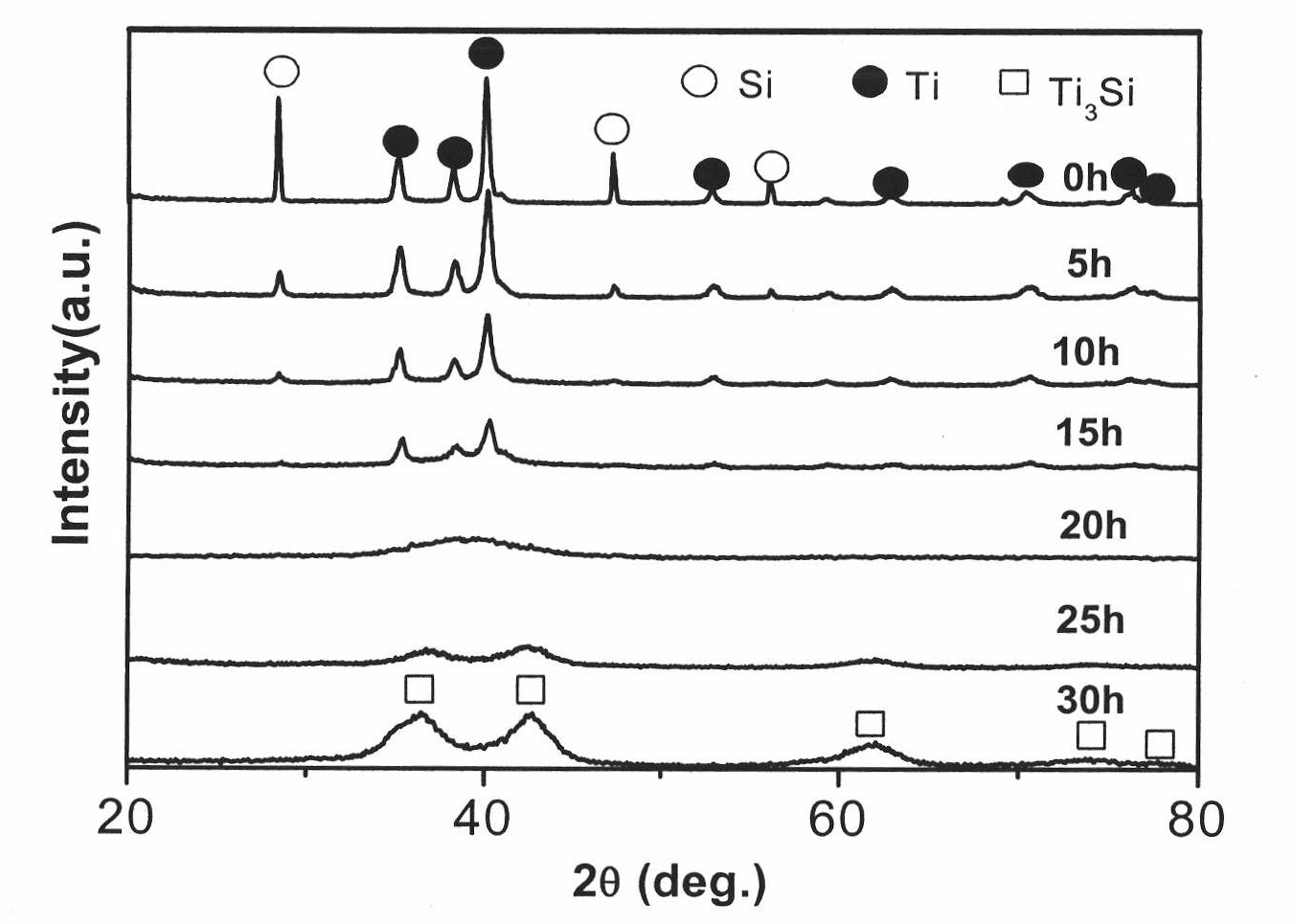

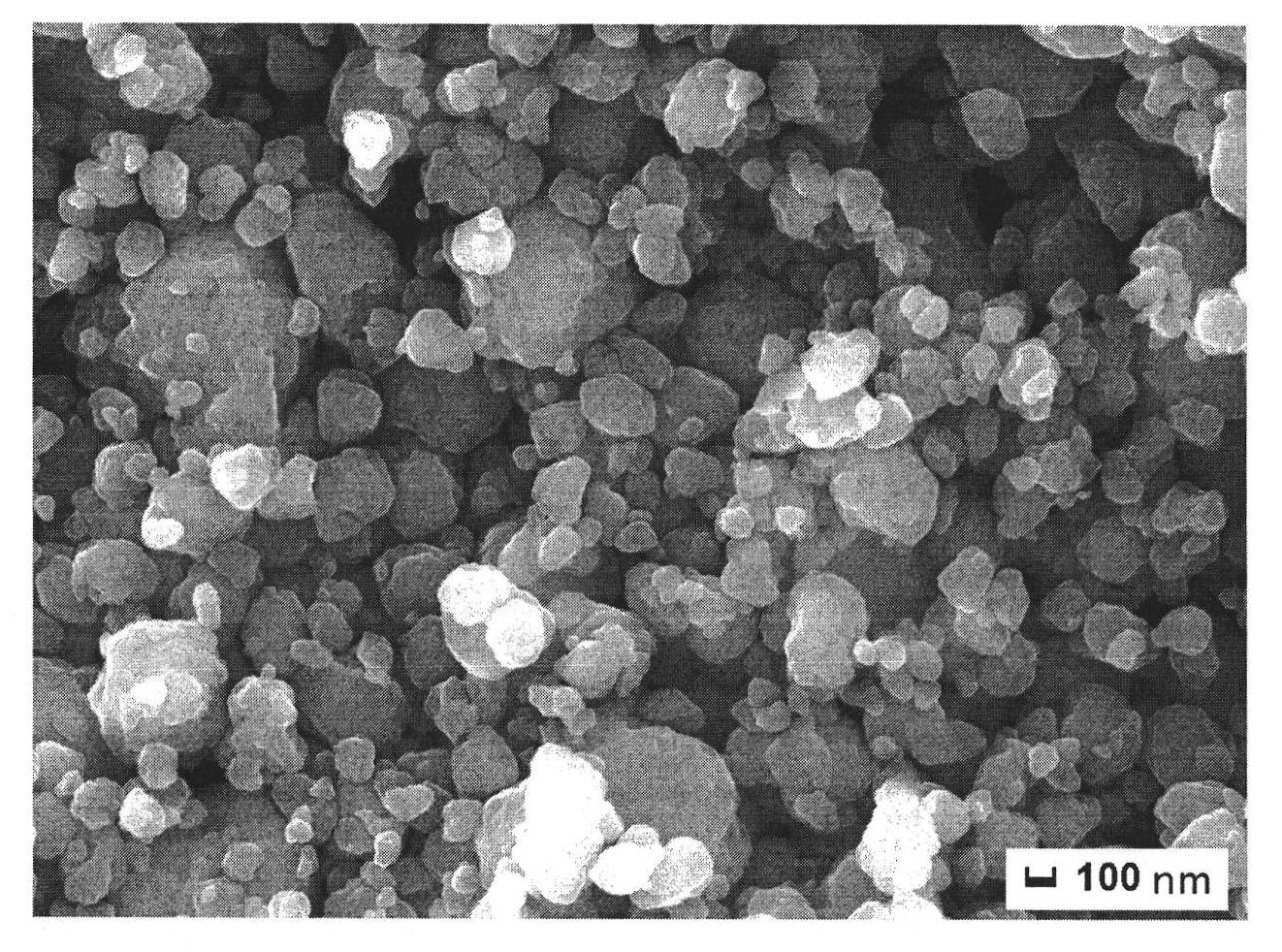

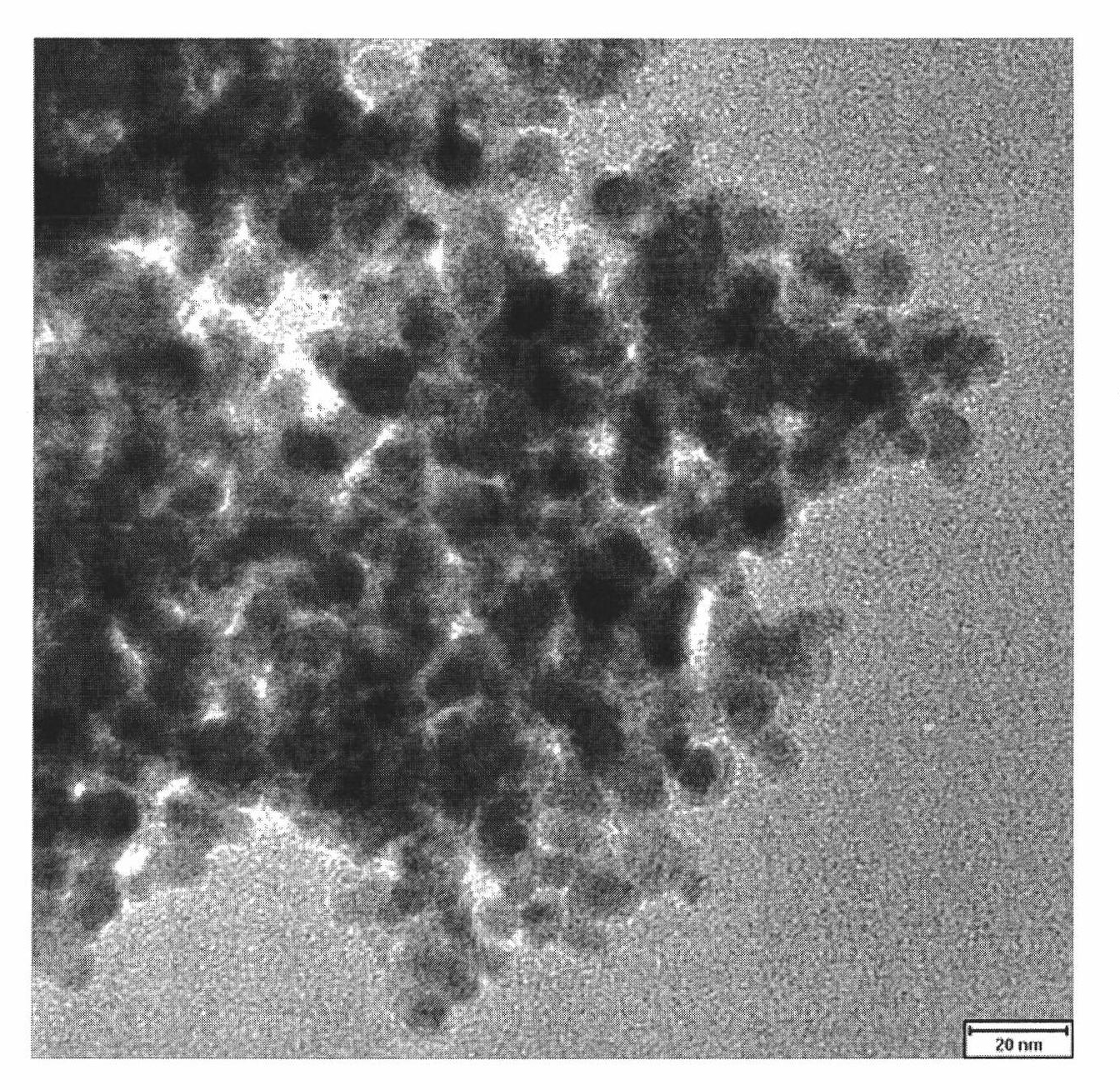

Embodiment 1

[0017] According to the molar ratio of 3:1, take respectively 20 g of analytically pure grade titanium powder (300 mesh) and 3.89 g of silicon powder (300 mesh), put them into the ball mill jar of the planetary high-energy ball mill after mixing them evenly in a mortar, and pour them into the ball mill jar. Add 10ml of alcohol as the liquid medium of the ball mill, evacuate the ball mill tank, pass in Ar (argon gas), the ventilation rate is 0.5L / min, and use three kinds of steel balls with diameters of 10mm, 6mm and 4mm respectively under 0.2Mpa 50 pieces each, ball mill the mixture for 12 hours, the voltage of the ball mill is 110V, and the speed of the ball mill is 200rad / min; after ball milling, put the mixture into a vibrating dryer, and raise the temperature to 50°C at a heating rate of 5°C / min Finally, vibrate and dry for 60 minutes to completely remove alcohol, then cool naturally to room temperature, and pass through a 300-mesh sieve to obtain the face-centered cubic Ti...

Embodiment 2

[0020] Weigh respectively 20 g of analytically pure grade titanium powder (300 mesh) and 4.67 g of silicon powder (300 mesh) according to the molar ratio of 3: 1.2, put them into the ball mill jar of the planetary high-energy ball mill after mixing them evenly in a mortar, and pour them into the ball mill jar Add 10ml of alcohol as the liquid medium of the ball mill, evacuate the ball mill tank, pass in Ar (argon gas), the ventilation rate is 0.5L / min, and use three kinds of steel balls with diameters of 10mm, 6mm and 4mm respectively under 0.2Mpa 50 pieces each, ball mill the mixture for 12 hours, the voltage of the ball mill is 110V, and the speed of the ball mill is 200rad / min; after ball milling, put the mixture into a vibrating dryer, and raise the temperature to 50°C at a heating rate of 5°C / min Finally, vibrate and dry for 60 minutes to completely remove alcohol, then cool naturally to room temperature, and pass through a 300-mesh sieve to obtain the face-centered cubic ...

Embodiment 3

[0023] Weigh respectively 20 g of analytically pure grade titanium powder (300 mesh) and 5.83 g of silicon powder (300 mesh) according to the molar ratio of 3: 1.5, put them into the ball mill jar of the planetary high-energy ball mill after mixing them evenly in a mortar, and pour them into the ball mill jar Add 10ml of alcohol as the liquid medium of the ball mill, evacuate the ball mill tank, pass in Ar (argon gas), the ventilation rate is 0.5L / min, and use three kinds of steel balls with diameters of 10mm, 6mm and 4mm respectively under 0.2Mpa 50 pieces each, ball mill the mixture for 12 hours, the voltage of the ball mill is 110V, and the speed of the ball mill is 200rad / min; after ball milling, put the mixture into a vibrating dryer, and raise the temperature to 50°C at a heating rate of 5°C / min Finally, vibrate and dry for 60 minutes to completely remove alcohol, then cool naturally to room temperature, and pass through a 300-mesh sieve to obtain the face-centered cubic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com