Method for simultaneously smelting hydrolysis slag, pyrite and zinc kiln slag by using blast furnace

A hydrolysis slag and blast furnace technology, which is applied in furnaces, blast furnaces, shaft furnaces, etc., can solve the problems of sulfur dioxide pollution, unsatisfactory zinc volatilization index, low zinc and copper volatilization rate, etc., and achieve environmental friendliness, simple and practical equipment, and separation good effect

Active Publication Date: 2010-08-25

云南云铜锌业股份有限公司

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the recovery and utilization of valuable elements in zinc kiln slag, known literature 1 (Zhou Hongwu, Xu Ziping. Recycling silver from zinc kiln slag by molten pool smelting method [J]. Nonferrous Metals (Smelting Part), 1991 (6): 18 ~20) Recovering valuable elements in zinc kiln slag by melting pool smelting method is only carried out to small scale experiment and the recovery rate of scattered metal is about 40%, and there are follow-up treatment and environmental pollution problems of sulfur dioxide

The known document 2 (Li Changfu. Experimental Research on Smelting Process of Fankou Kiln Slag. Mining and Metallurgy. 2002, 11(3): 56-59) treats zinc kiln slag with pyrite vulcanization technology, which can recover zinc kiln slag Valuable elements in the process, but the process has only been studied in the laboratory and the sulfur dioxide produced in the process will affect the processing environment

Publicly known document 3 (Liu Zhihong, Wen Jian, Li Yuhu, etc. Research on Comprehensive Recovery of Valuable Metals from Fankou Kiln Slag Treated by Fusion Chlorination and Volatilization Process [J]. Nonferrous Metals (Smelting Section), 2005(3): 14-15 ) using fusion chlorination method to recover valuable elements in zinc kiln slag from flue dust. The volatilization rate of zinc and copper is low, and the volatilization index of zinc is not ideal. The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

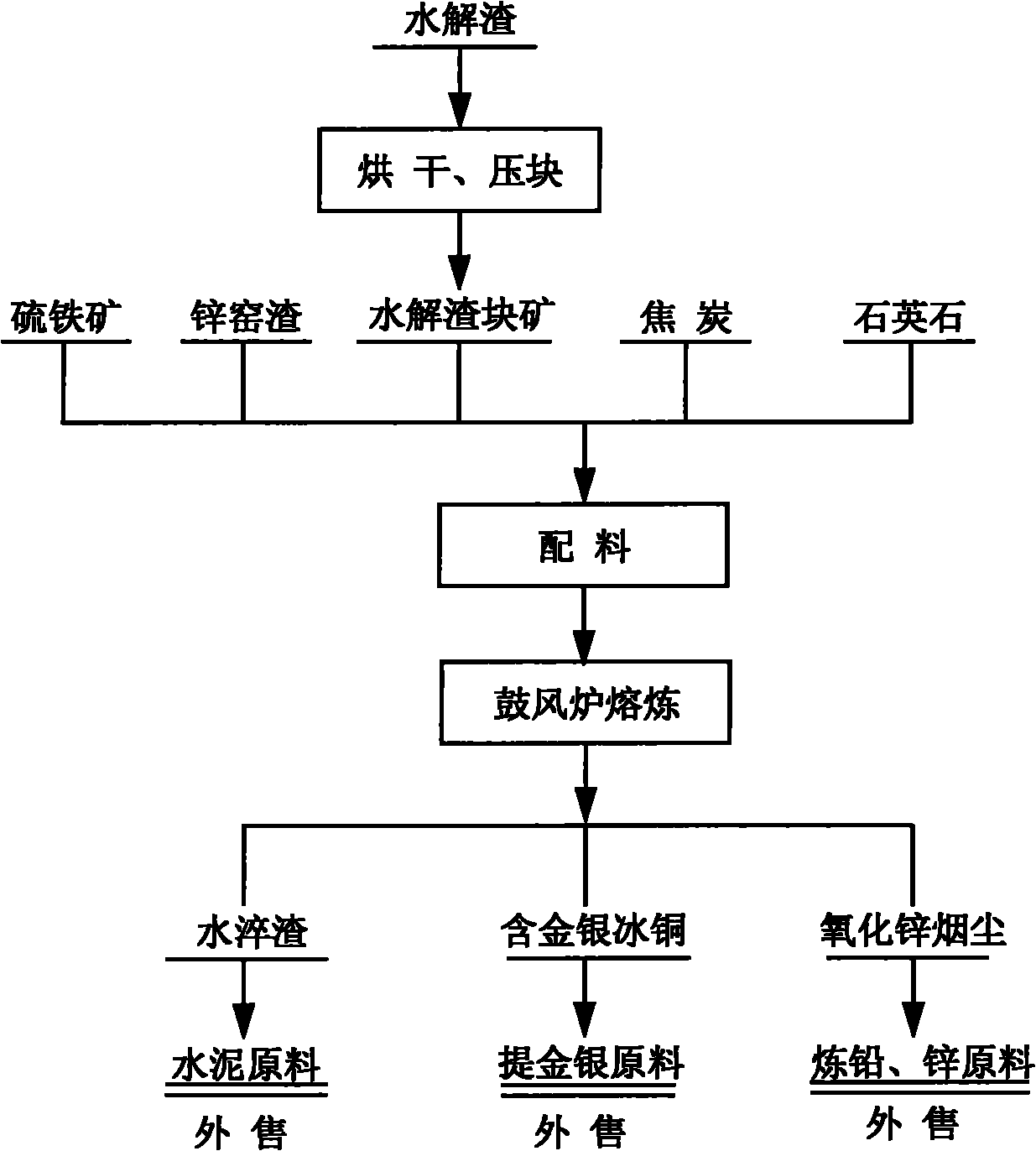

The invention relates to a method for simultaneously smelting hydrolysis slag, zinc kiln slag and pyrite by using a blast furnace, which belongs to the technical field of metal smelting. The method comprises the following steps: a, taking a proper amount of hydrolysis slag, drying the hydrolysis slag with hot air to meet the moisture requirement of 6 to 14 percent, then briquetting the hydrolysis slag, and naturally drying the briquette for 10 to 16 hours for later use; b, taking 55 to 71 percent of zinc kiln slag of which over 80 percent meets the initial granularity requirement of 10 meshes, adding 9 to 20 percent of hydrolysis slag briquette, 13 percent of coke, 3 to 5 percent of quartzite and 4 to 7 percent of pyrite into the zinc kiln slag, naturally mixing the five materials and then smelting the mixture in the blast furnace; c, smelting the mixture in the blast furnace, wherein the smelting temperature is between 600 and 1,350 DEG C, the smelting period is 40 to 80 minutes, the material column height is 1.5 to 1.8 meters and the volume of blast is 7,000 to 8,000 m<3> / h; and d, reclaiming the gold and sliver-containing copper matte obtained after smelting to obtain a raw material for smelting copper, reclaiming zinc and lead valuable elements in the soot to directly obtain raw materials for smelting zinc and lead, and directly using water granulated slag as a raw material for producing cement. The method has the advantages of simultaneously obtaining the copper matte, the water granulated slag and the soot serving as primary products through one process, realizing efficient separation and zero emission of the valuable elements, along with environmental protection.

Description

A method for simultaneously smelting hydrolyzed slag, pyrite and zinc kiln slag with a blast furnace Technical field: The invention relates to a method for extracting valuable elements in hydrolyzed slag, pyrite and zinc kiln slag. Specifically, a blast furnace is used to simultaneously smelt hydrolyzed slag, pyrite and zinc kiln slag to obtain gold-silver matte and zinc oxide Method of soot and water quenching slag. It belongs to the technical field of metal smelting. technical background: The hydrolysis slag is a mixture of the leaching filtrate produced by secondary zinc oxide powder treatment and the hydrolyzed indium filtrate, and the filter residue obtained by plate pressure filtration after the iron precipitation process of hydrolysis and iron precipitation. The filter residue contains valuable elements such as zinc, lead, copper, iron, sulfur and silver. The zinc smelting industry usually uses rotary kiln volatilization to extract zinc and lead. Other valuable el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/04C22B19/08C22B15/02C22B11/00C22B13/02C04B7/147

CPCY02P10/20Y02P40/10

Inventor 牛皓张放戴兴征杨美彦黄江张会林杨建军李永祥郭大为邓蕊黄孟阳吕萍

Owner 云南云铜锌业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com