Polyamine flue gas desulfurizer and preparation method thereof

A technology of amine amide and desulfurizer, applied in the field of renewable polyamine amide flue gas desulfurizer and its preparation, can solve the problems of low utilization rate of absorbent, high industrial cost and operating cost, unfavorable practical application of industrial production, etc. , to achieve the effect of reducing electron cloud density, renewable energy consumption and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A three-necked flask, a condensation reflux tube, a nitrogen vent tube, a sealed constant pressure dropping funnel and a constant temperature stirring water bath were assembled into a closed condensation reflux reaction device with nitrogen. Dissolve 0.2mol of diethylenetriamine in 30mL of toluene, add 0.1mol of methyl acrylate under nitrogen protection and stirring, and keep the temperature at 20 °C. After 24h of reaction, extract with 200mL of distilled water four times, and extract the water layer for four times. Collected together, distilled under reduced pressure to remove water, and the resulting product was denoted as T1. Continue vacuum distillation for T1, and take the fractions at 140±2°C, 165±2°C and 188±2°C, and record them as T2, T3 and T4, respectively.

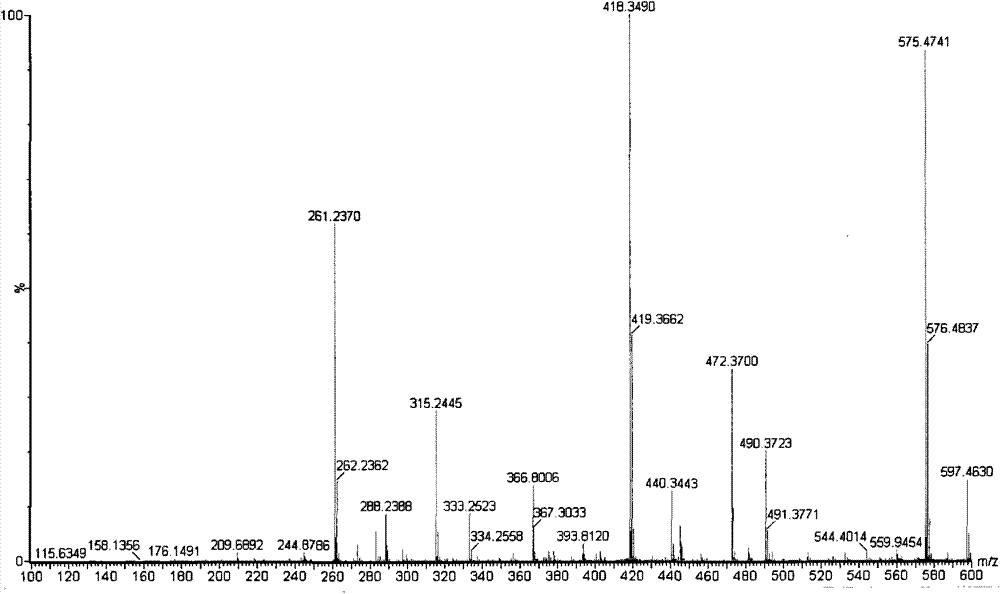

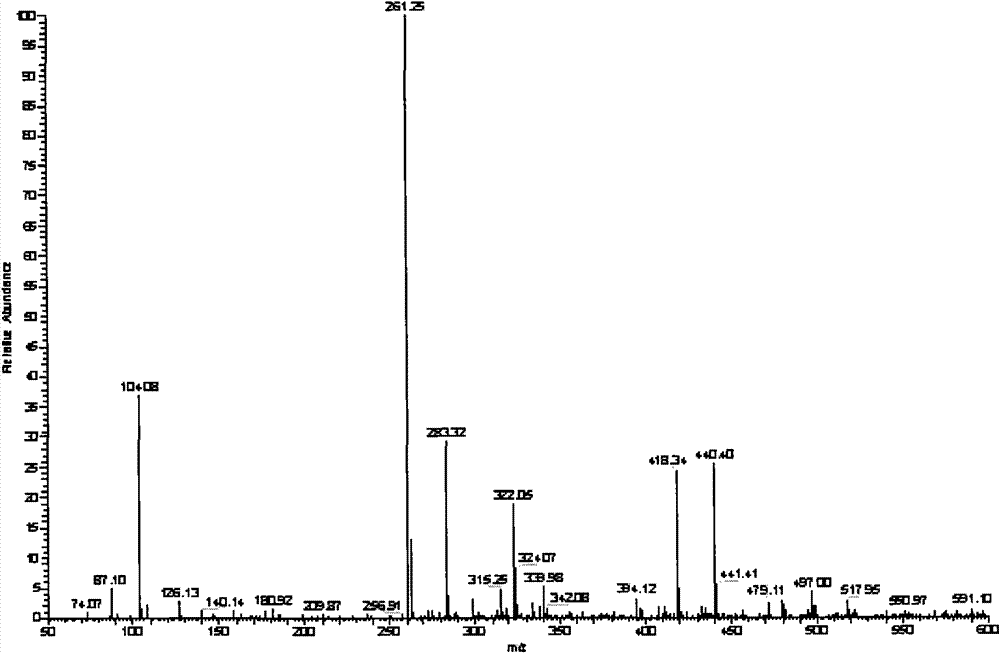

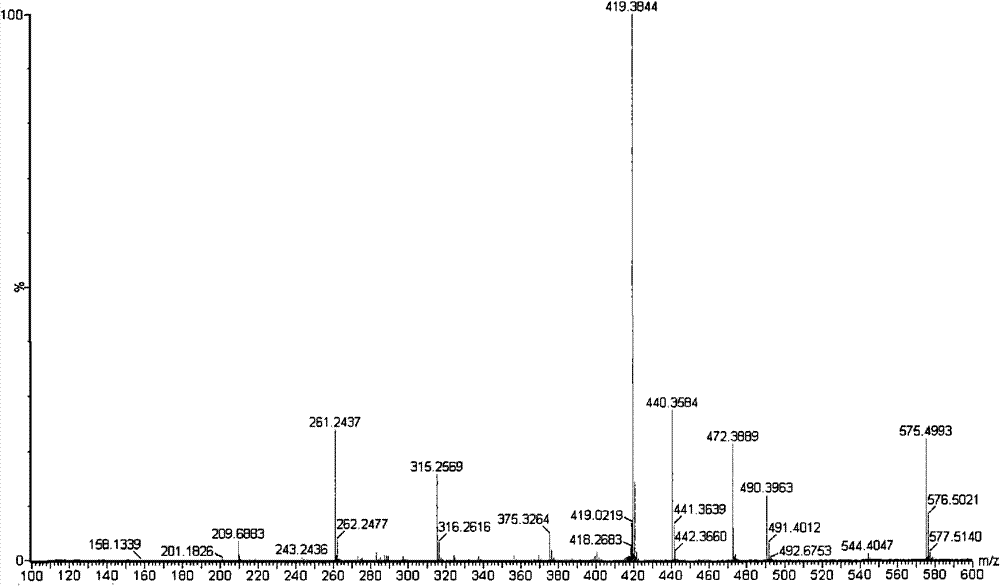

[0027] figure 1It is the electrospray mass spectrum of the polyamine amide mixture T1 prepared by the present invention, the m / z value of the mass-to-charge ratio of the abscissa is the ratio of the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com