Preparation method of blue aluminate fluorescent powder with high brightness and high stability

A high-stability, aluminate technology, applied in the field of material manufacturing, can solve problems such as damage to the brightness and luminous efficiency of phosphors, grain crystal defects, etc., and achieve the effects of easy industrial production, uniform particle size, and improved brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

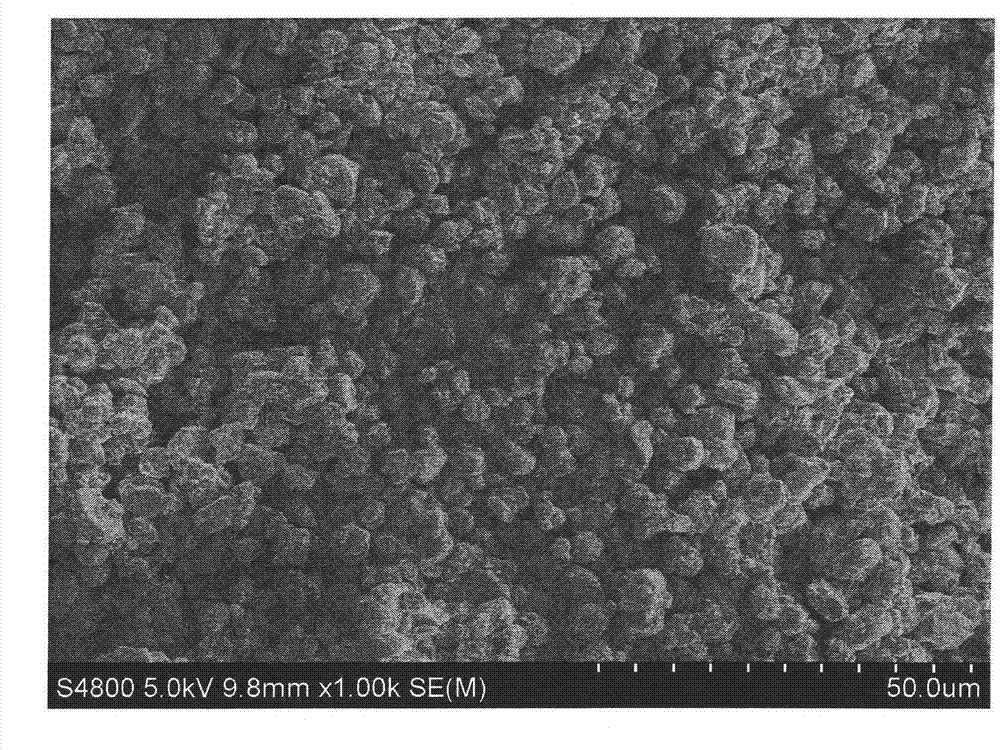

Image

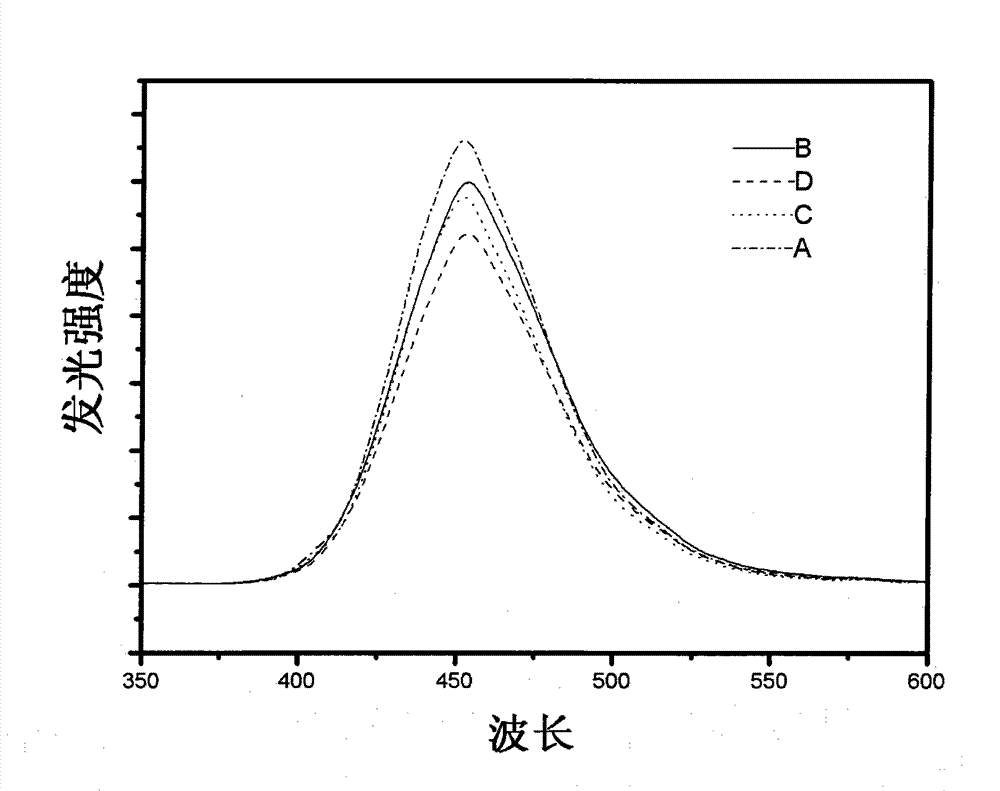

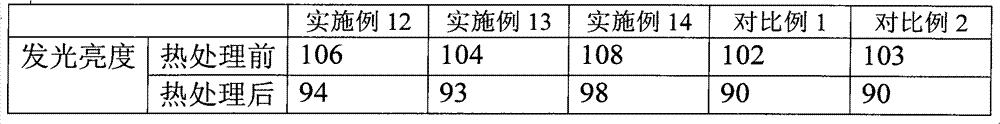

Examples

Embodiment 1

[0037] According to the chemical expression Ba of the blue aluminate phosphor 0.9 MgAl 10 o 17 :0.1Eu 2+ According to the stoichiometric ratio of this chemical formula, aluminum oxide, aluminum nitride, barium sulfate, magnesium oxide and europium oxide are respectively taken to form the starting material, ammonium bicarbonate is taken by 2% of the starting material quality, and ammonium bicarbonate is obtained by 7.3 grams of starting material The ratio of adding 100ml of absolute ethanol to the mixture, taking absolute ethanol, mixing the starting material, ammonium bicarbonate and absolute ethanol, and ball milling for 10 hours to obtain a raw material powder with a central particle size of 0.9-2.1 μm; place the raw material powder In an air-filled environment, raise the ambient temperature to 1100°C at a heating rate of 5°C / min, keep it warm for 10 hours, and cool to room temperature to obtain a calcined powder; First wash in dilute hydrochloric acid at a temperature of...

Embodiment 2

[0039] According to the chemical expression Ba of the blue aluminate phosphor 0.9 MgAl 10 o 17 :0.1Eu 2+ According to the stoichiometric ratio of the chemical formula, aluminum oxide, aluminum nitride, barium carbonate, magnesium oxide and europium oxide are respectively taken to form the starting material, aluminum fluoride is taken according to 6% of the starting material mass, and then starting from 7.3 grams The ratio of adding 150ml of absolute ethanol to the starting material, taking absolute ethanol, mixing the starting material, aluminum fluoride and absolute ethanol, and ball milling for 24 hours to obtain a raw material powder with a central particle size of 0.9-2.1 μm; the raw material The powder is placed in an environment with a reducing atmosphere, the reducing atmosphere is composed of 90% nitrogen and 10% hydrogen by volume; the ambient temperature is raised to 1700°C at a heating rate of 10°C / min, and the temperature is kept for 2 hours. Then, cool to room ...

Embodiment 3

[0041] According to the chemical expression Ba of the blue aluminate phosphor 0.9 MgAl 10 o 17 :0.1Eu 2+ According to the stoichiometric ratio of the chemical formula, aluminum oxide, aluminum nitride, barium carbonate, magnesium oxide and europium oxide are respectively taken to form the starting material, lithium carbonate is taken according to 4% of the starting material quality, and then 7.3 grams of starting material Add 125ml of absolute ethanol to the raw material, take absolute ethanol, mix the starting material, lithium carbonate and absolute ethanol, and ball mill for 17 hours to obtain a raw material powder with a central particle size of 0.9-2.1 μm; place the raw material powder In an environment where a reducing atmosphere is introduced, the reducing atmosphere is composed of 95% nitrogen and 5% hydrogen by volume; at a heating rate of 7.5°C / min, the ambient temperature is raised to 1400°C, kept for 6 hours, and cooled to room temperature to obtain a calcined p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com