Electroconductive paste composition and the method of producing the same

A technology of electrical conductivity and composition, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as fire and explosion, and achieve low contact resistance, good conductivity, and good adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Silver powder treated with 10% silver oxide with an average particle size of 400nm 50g

[0133] (manufactured by Mitsui Kinzoku Co., Ltd., FHD, crystallite diameter less than 10nm)

[0134] 5 g of a 10% by mass aqueous solution of cocoaminoacetate

[0135] (Alkylamine salt type cationic surfactant)

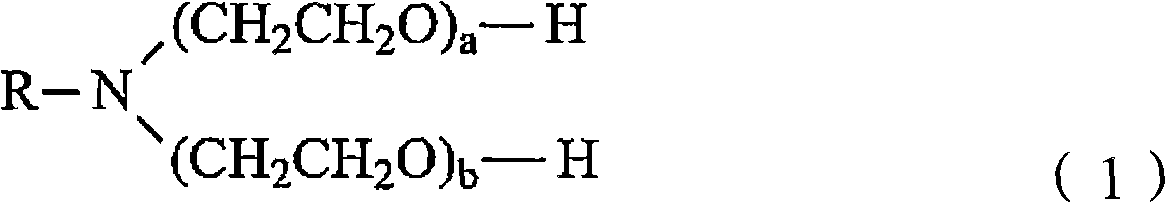

[0136] 0.5 g of a 10% by mass aqueous solution of polyoxyethylene cocoalkylamine ether

[0137] (Alkylamine type nonionic surfactant)

[0138] water 50g

[0139] The above materials and 400 g of zirconia beads with a diameter of 2 mm were put into a polyethylene bottle with a volume of 250 ml, mixed, and mixed for 4 hours using a rotary machine (ball mill) to obtain a silver particle dispersion (a).

[0140] Transfer 100 g of the silver powder dispersion (a1) to a flat tray with bottom dimensions of 200 mm long x 150 mm wide, preliminarily freeze-dry, and then vacuum freeze-dry using "DFM-05AS" manufactured by Nippon Vacuum Co., Ltd. Load the dispersion (a1) of the sil...

Embodiment 2

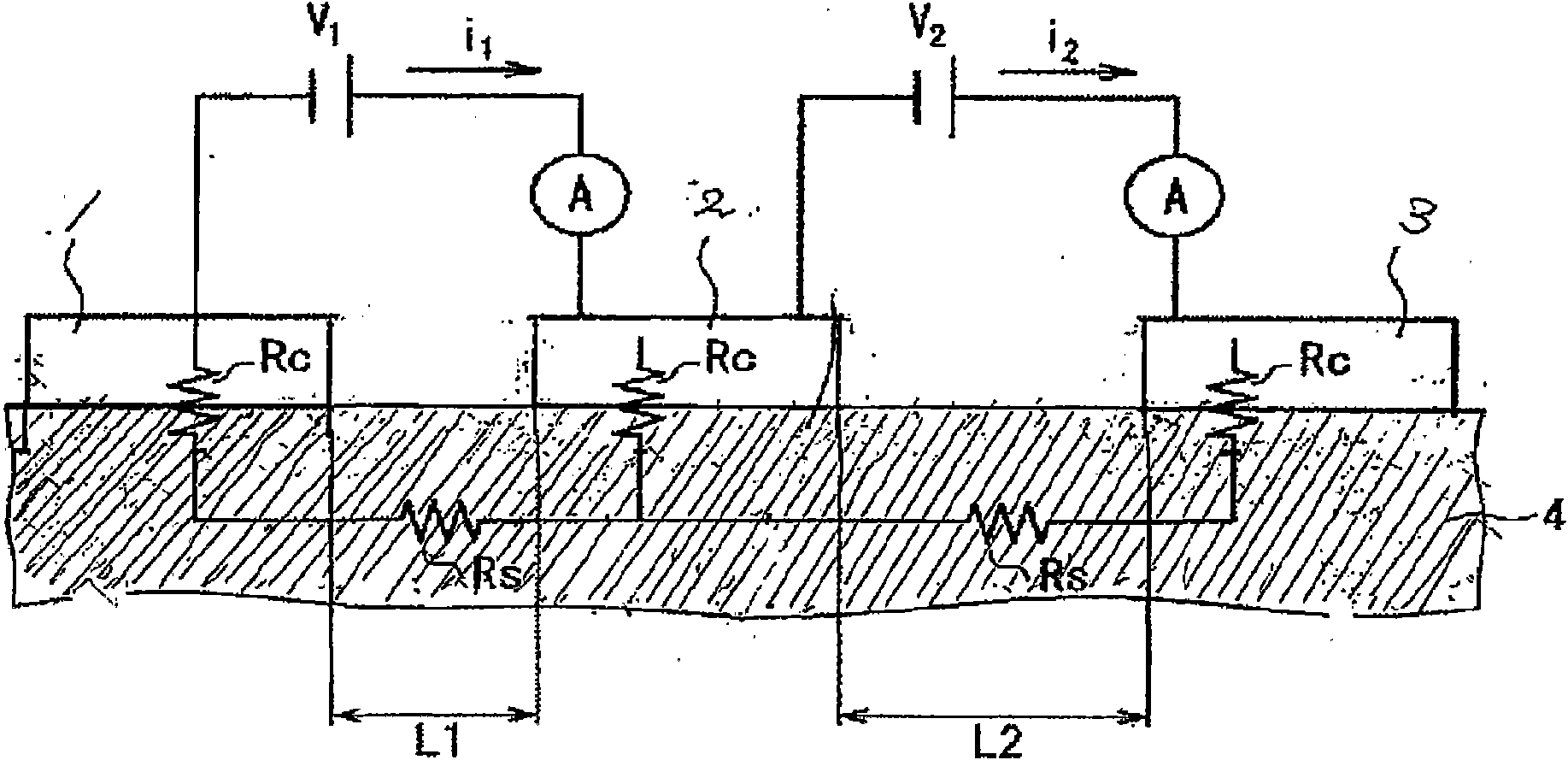

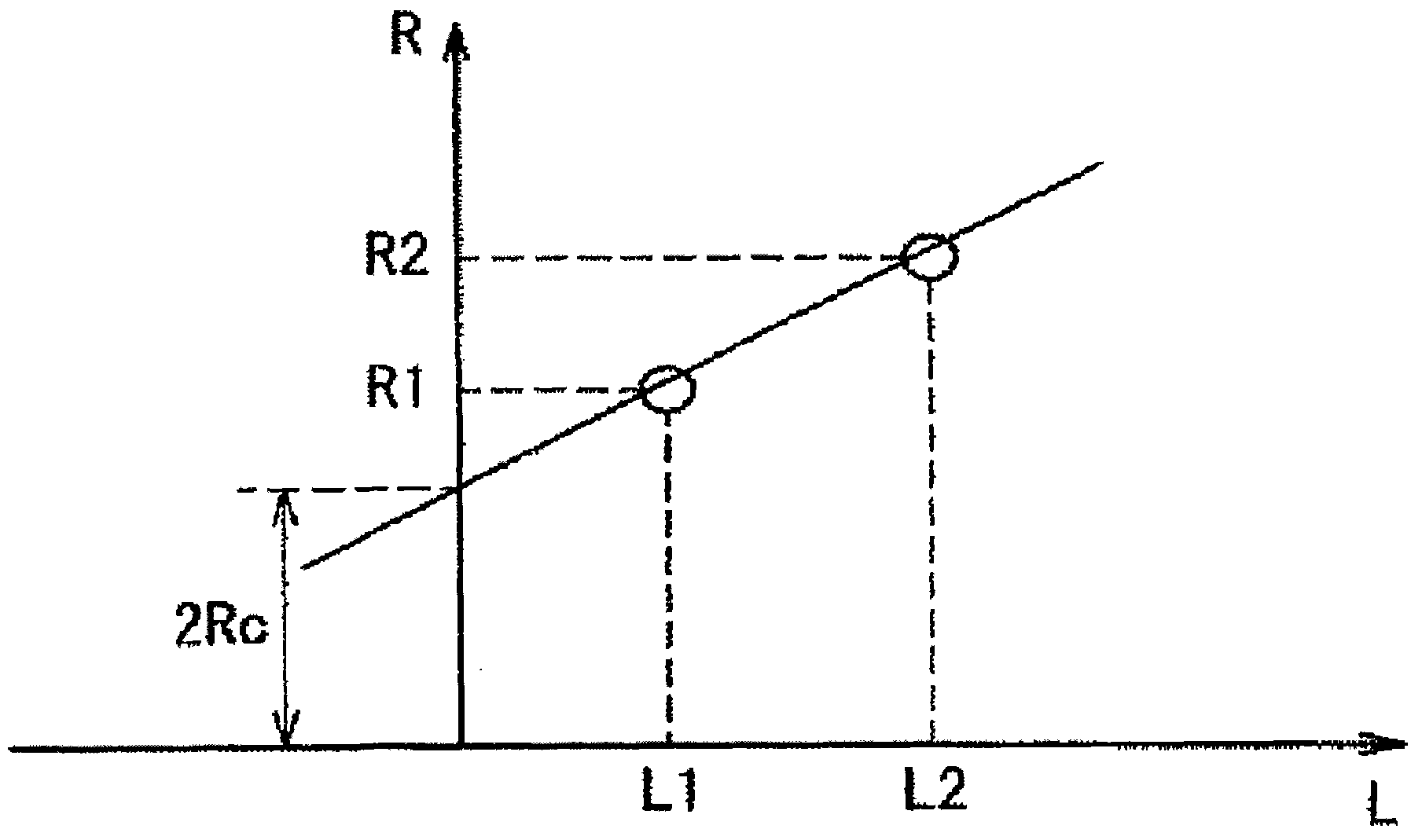

[0189] Except using the fluororesin " VITON A-500 " (manufactured by DuPont) of fluorine content 66% instead of DYNEON FC-2211 in the embodiment 1 as the fluororesin, with the same method as the embodiment 1, obtain the silver paste (B2 ). Screen printing on PET results in repeatable prints without blurring or uneven colors. The volume resistivity is 2.08×10 -5 Ω·cm. By screen printing using a mask film with a printed pattern and silver paste (B2), printing was repeated on an ITO-deposited glass plate in the same manner as in Example 1 to obtain a rectangular printed coating film and printed pattern. . No printing failure was observed. The average thickness of the rectangular printed coating film was 11.9 μm. Measure the volume resistivity, the average is 2.08×10 -5 Ω·cm. In addition, when the contact resistance was measured by the TLM method, it was 0.411Ω. When the above coating film was immersed in saturated saline at room temperature for 120 hours, no change in sur...

Embodiment 3

[0225] 33g of silver powder (TC-38S, manufactured by Deli Chemical Co., Ltd.) with a volume average particle diameter of 1.26 μm and 7 g of fluorine resin (DYNEONFC-2211, manufactured by Sumitomo 3M Co., Ltd.) with a fluorine content of 7 g were dissolved in butyl cellosolve acetic acid Esters and 2,2,4-trimethyl-1,3-pentanediol diisobutyrate 50:50 mixed solution 11.5g, form varnish solution, this varnish solution and 2mm diameter zirconia beads of 400g The mixture was put into a 250 cc polyethylene bottle, mixed and stirred with a shaker for 4 hours, and a silver paste was obtained.

[0226] This silver paste was coated on PET with a thickness of 50 μm using an applicator, and the formed coating film was fired at 230° C. for 30 minutes, and the film thickness and volume resistivity were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallite diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com