Method for treatment of silk degumming wastewater and recovery of silk gum

A technology for wastewater and sericin, which is applied in the field of wastewater treatment, silk floss degumming wastewater treatment and sericin recovery, can solve the problems of sericin protein easily deteriorated, low retention rate, difficult to adjust pH value, etc., and achieves subsequent processing. The purification and application are convenient, the treatment method is simple, and the effect of maintaining chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for treating silk floss degumming waste water and reclaiming sericin, comprising the steps of:

[0028] (1) carry out primary filtration to waste water;

[0029] (2) Precipitation is carried out by the acid analysis method, and the citric acid is added dropwise to the waste water while stirring. The stirring rate is 60 rpm. 3. At 8 o'clock, stop adding acid and stirring, let it stand for stratification, and after 2 hours, the stratification is stable, and it is divided into supernatant liquid and lower layer precipitation;

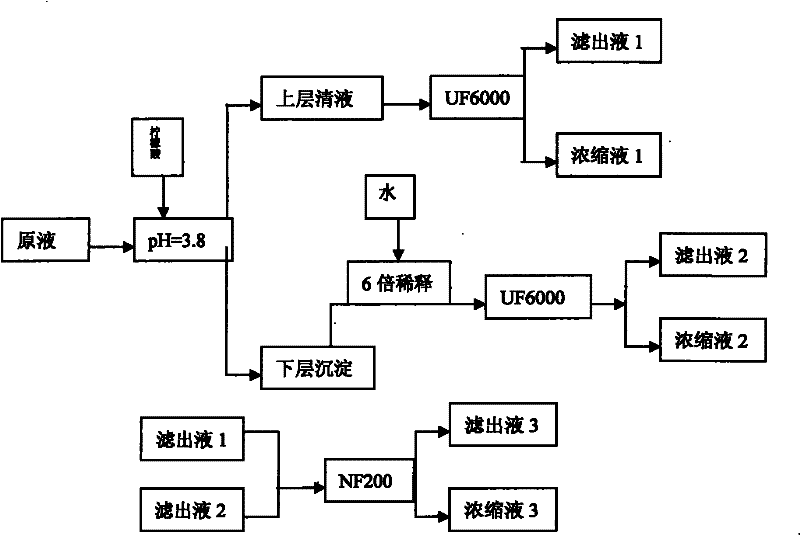

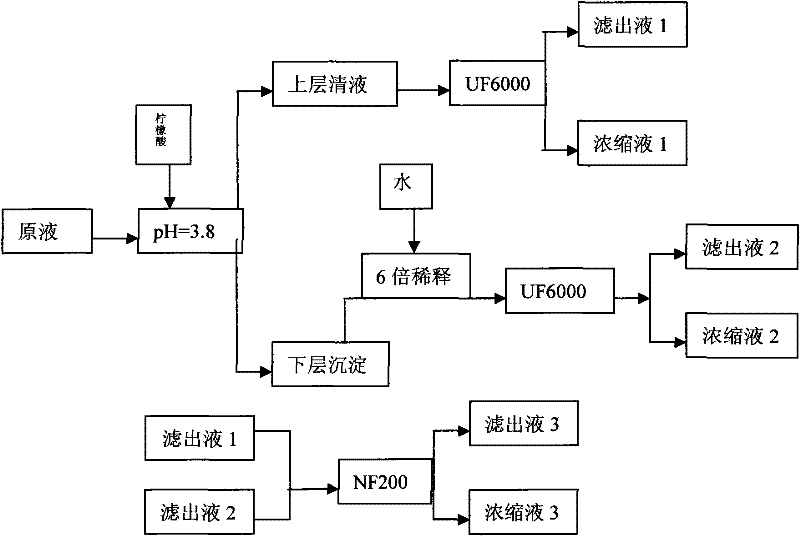

[0030] (3) Pour the supernatant and pass through the ultrafiltration membrane to obtain the first filtrate and the first concentrated solution; the lower precipitate is diluted with deionized water and then passed through the ultrafiltration membrane to remove the contained Salt, obtain the second filtrate and the second concentrate; The ultrafiltration membrane is a hollow fiber ultrafiltration membrane with a molecular weight cut-off of ...

Embodiment 2

[0041]A treatment method for silk floss degumming wastewater. In the pilot test stage, the amount of silk degumming wastewater is 8 tons a day. The wastewater first passes through grids and screens with a distance of 25 mm to remove coarse solid impurities, and then is discharged into a volume of 10m 3 It is located in the regulating pool below the ground, and then, use the ZS50-32-200 / 3.0 stainless steel horizontal single-stage centrifugal pump to input the wastewater in the regulating pool into the precision filter (with a non-woven filter bag with a pore size of 10 μ inside), and filter After the solid impurities larger than 10μ are removed, they are discharged into the isoelectric point precipitation tank on the platform; the volume of the precipitation tank is 1.5m 3 , the actual amount of wastewater treated each time is 1m 3 , the height on the platform is made of PVC plastic or ceramics, and the volume is 0.08m 3 citric acid tank, when operating, wait for the amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com