Method for synthesizing carbon micron-spheres

A carbon sphere and micron technology, applied in the field of hollow or solid micron carbon spheres, can solve the problems of wide size distribution, difficult to accurately control physical parameters, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

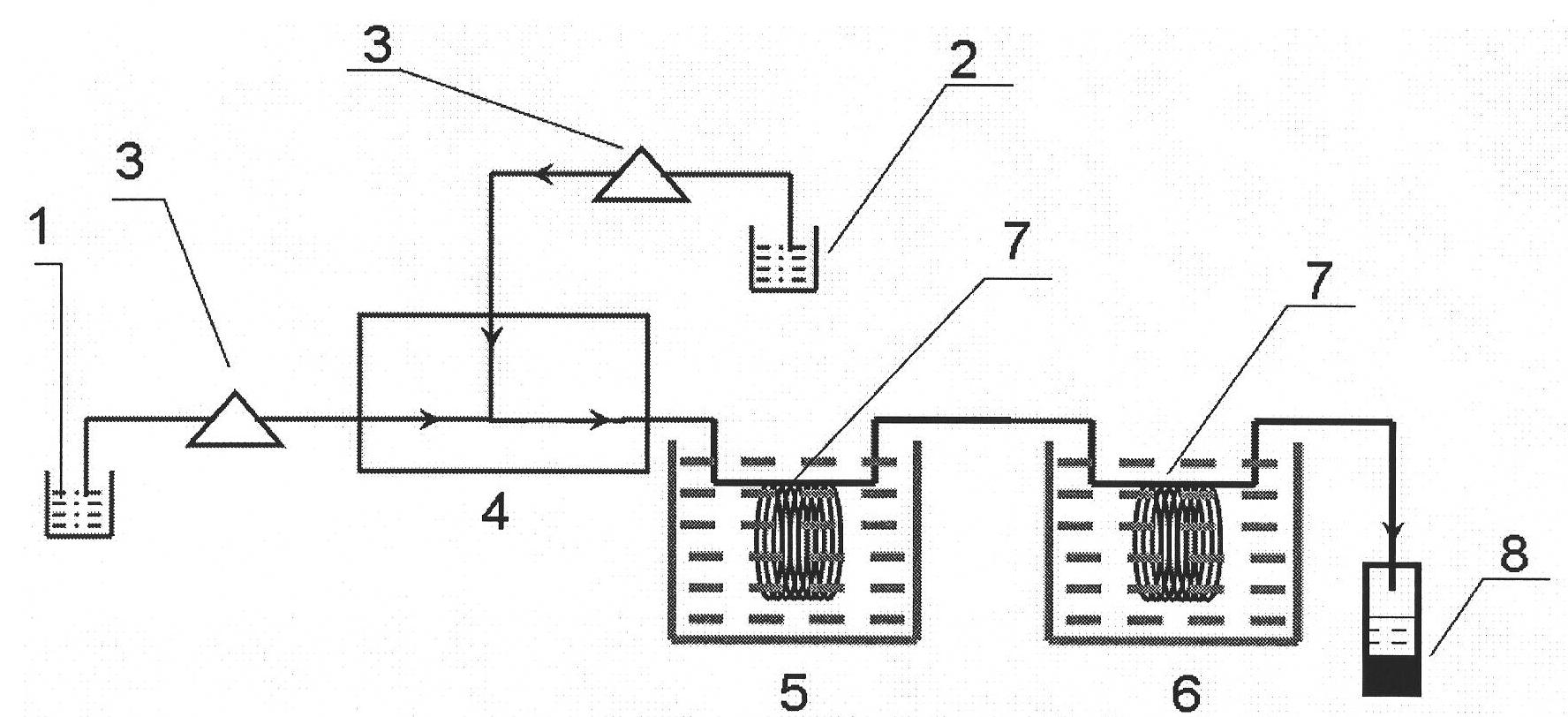

Method used

Image

Examples

Embodiment 1

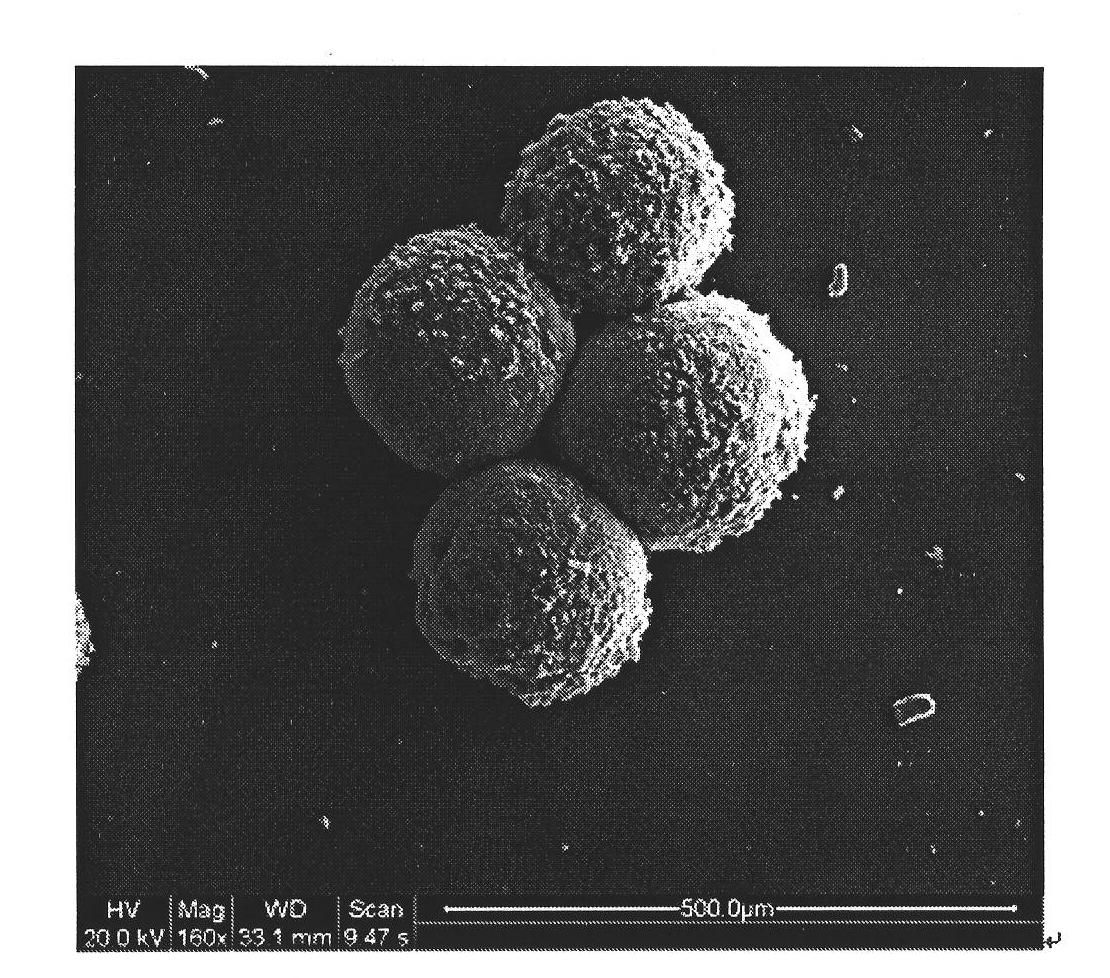

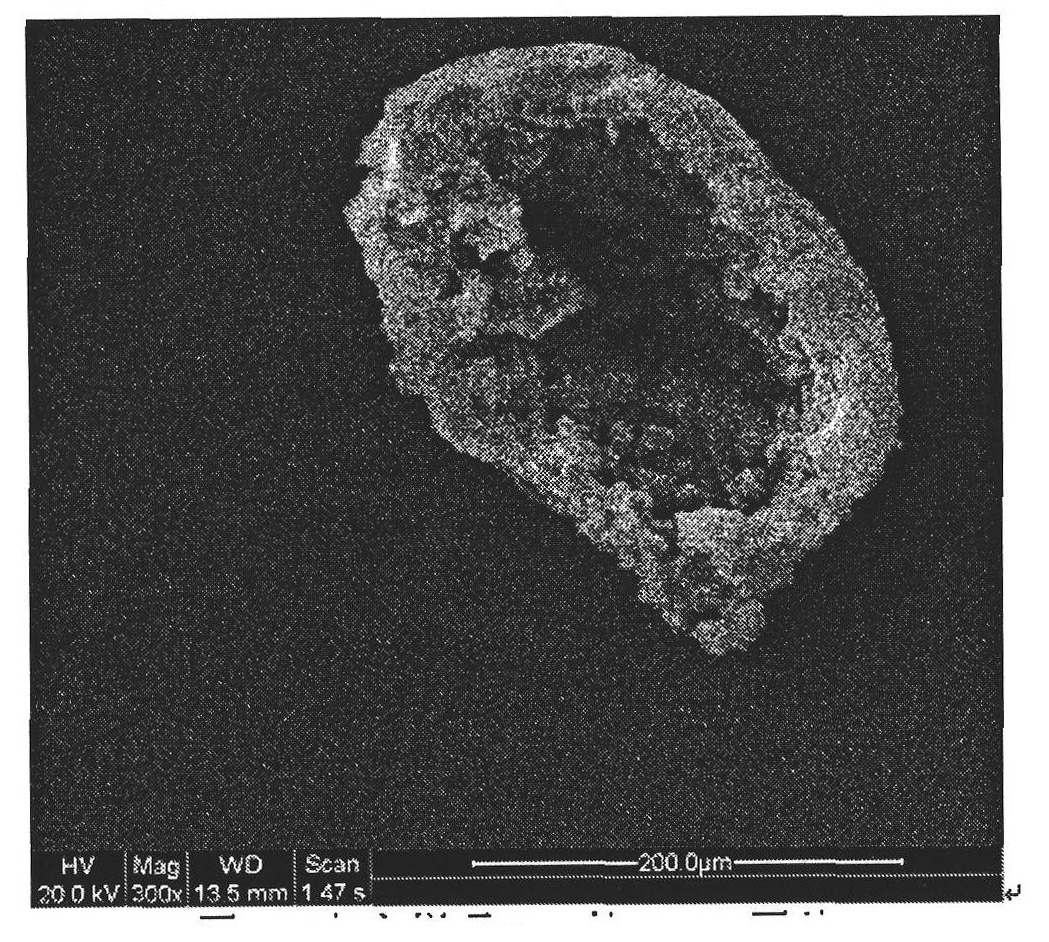

[0022] Add 1 g of furfuryl alcohol into 9 g of toluene, and stir evenly to obtain a 10% furfuryl alcohol solution. Next, add 10 g of concentrated sulfuric acid into water, stir and dissolve to obtain a 5 mol / L sulfuric acid solution. The furfuryl alcohol solution and the sulfuric acid solution were transported into a polyvinyl chloride capillary microreactor with a size of 0.5 mm by using two syringe pumps with a two-phase volume flow ratio of 80, wherein the inlet channel size of the furfuryl alcohol solution was 0.5 mm, and the sulfuric acid solution was The inlet channel size of the solution was 0.1 mm. The temperature of the oil bath for the pre-polymerization reaction was controlled to be 80°C, and the reaction time was 100s; the reaction was continued, the temperature was controlled to be 30°C, and the reaction time was 80h; the product was obtained. The reaction product was centrifuged, washed with absolute ethanol and n-hexane, baked in an oven at 30°C for 24 hours, a...

Embodiment 2-3

[0023] Embodiment 2-3 (oil phase kind)

[0024] Adopt the same method as Example 1 to carry out the test, but adopt different water-insoluble oil phases to prepare 10% furfuryl alcohol solution. The furfuryl alcohol solution was prepared with ethyl acetate and fatty acid methyl ester respectively, and the products obtained by the reaction were designated as samples A2 and A3, respectively. The average size of the obtained hollow carbon spheres was 210 and 208 μm, and the wall thickness was 20 and 18 μm, respectively, by scanning electron microscope characterization. It can be seen that under the same reaction conditions, changing the type of oil phase has no significant effect on the average size and wall thickness of the final hollow carbon spheres.

Embodiment 4-8

[0025] Embodiment 4-8 (kind and concentration of acid)

[0026] Experiments were carried out in the same manner as in Example 1, but with changes in the type and concentration of the acid catalyst. Prepare 8, 10, 8, 10, 18 mol / L aqueous acid catalyst solutions with acetic acid, hydrochloric acid, phosphoric acid, nitric acid and p-toluenesulfonic acid respectively, and the products obtained by the reaction are respectively designated as samples A4, A5, A6, A7 and A8. The average size of the hollow carbon spheres was 300, 400, 543, 354, and 376 μm, and the wall thicknesses were 15, 35, 55, 64, and 55 μm, respectively, by scanning electron microscopy. It can be seen that under the same reaction conditions, changing the type and concentration of the acid catalyst will lead to changes in the size and wall thickness of the prepared hollow carbon spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com