Microbial additive for silage fodder and preparation method thereof

A microbial additive and silage technology, applied in the field of silage, can solve side effects and other problems, and achieve the effects of making up for losses, shortening fermentation time, and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

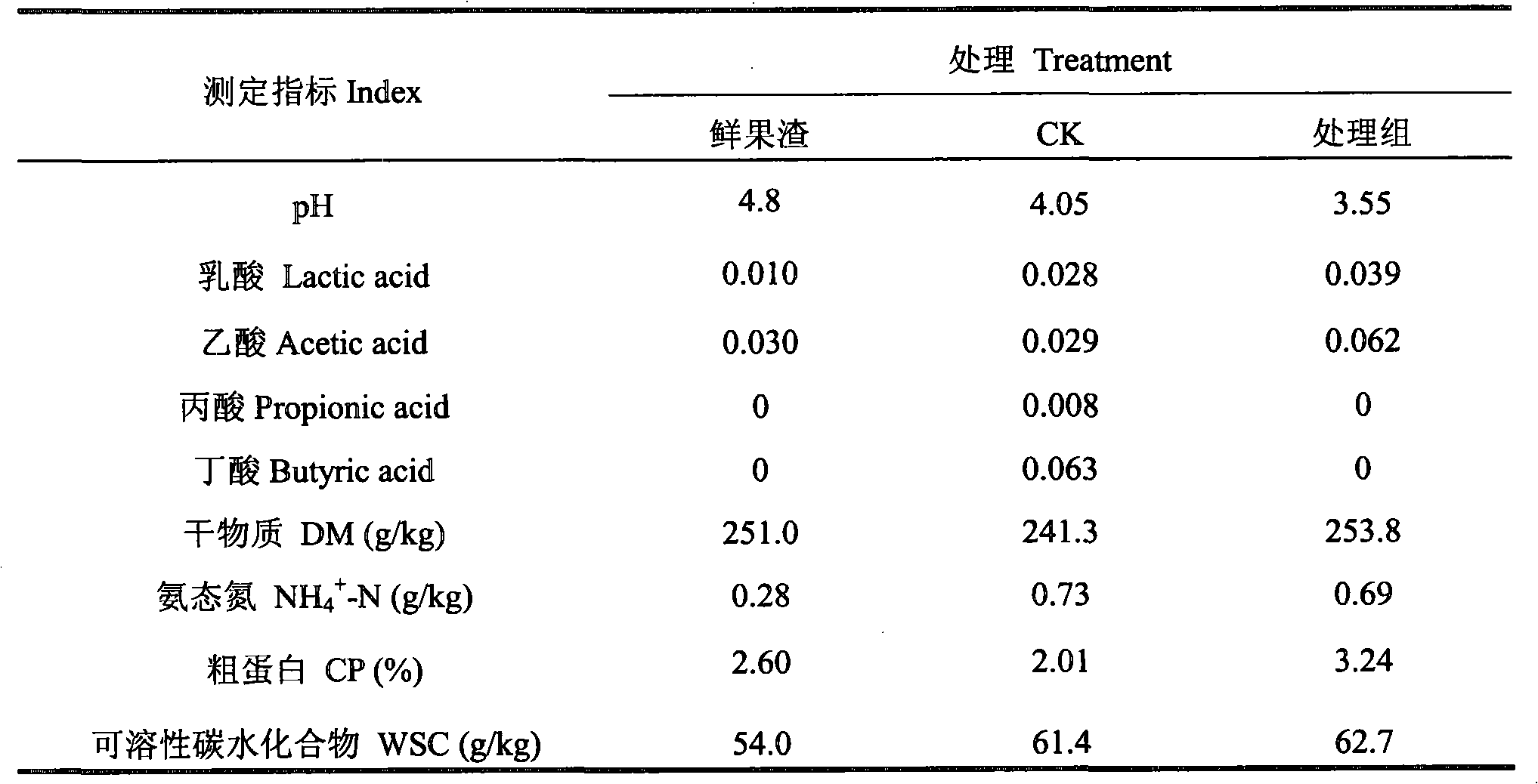

[0016] Embodiment 1: The present embodiment provides a kind of silage microbial additive, and using method thereof, fully mixes with apple pomace according to the following microbial formula: with fresh apple pomace as silage raw material, add plantaractobacillus respectively (number of bacteria is 5.0 ×10 9 ~1.0×10 10 cfu / mL) and Pediococcus pentosacea (the number of bacteria is 5.0×10 9 ~1.0×10 10 cfu / mL) liquid culture solution 0.1%~0.5% (dosage is calculated according to the amount of additives per ton of silage, for example, 1 ton of silage is added with 1~5kg of culture solution, the same below), aroma-producing yeast (the number of bacteria is 2.0×10 8 ~6.0×10 8 cfu / mL) liquid culture solution 0.1%~0.3%, Bacillus cereus (the number of bacteria is 1.0×10 8 ~5.0×10 8 cfu / mL) 0.1% to 0.2% liquid culture solution, fully stirred and mixed, put into a 40*80cm silage bag, squeeze out the air in the bag and seal it, and culture it at room temperature in the dark for 20 to ...

Embodiment 2

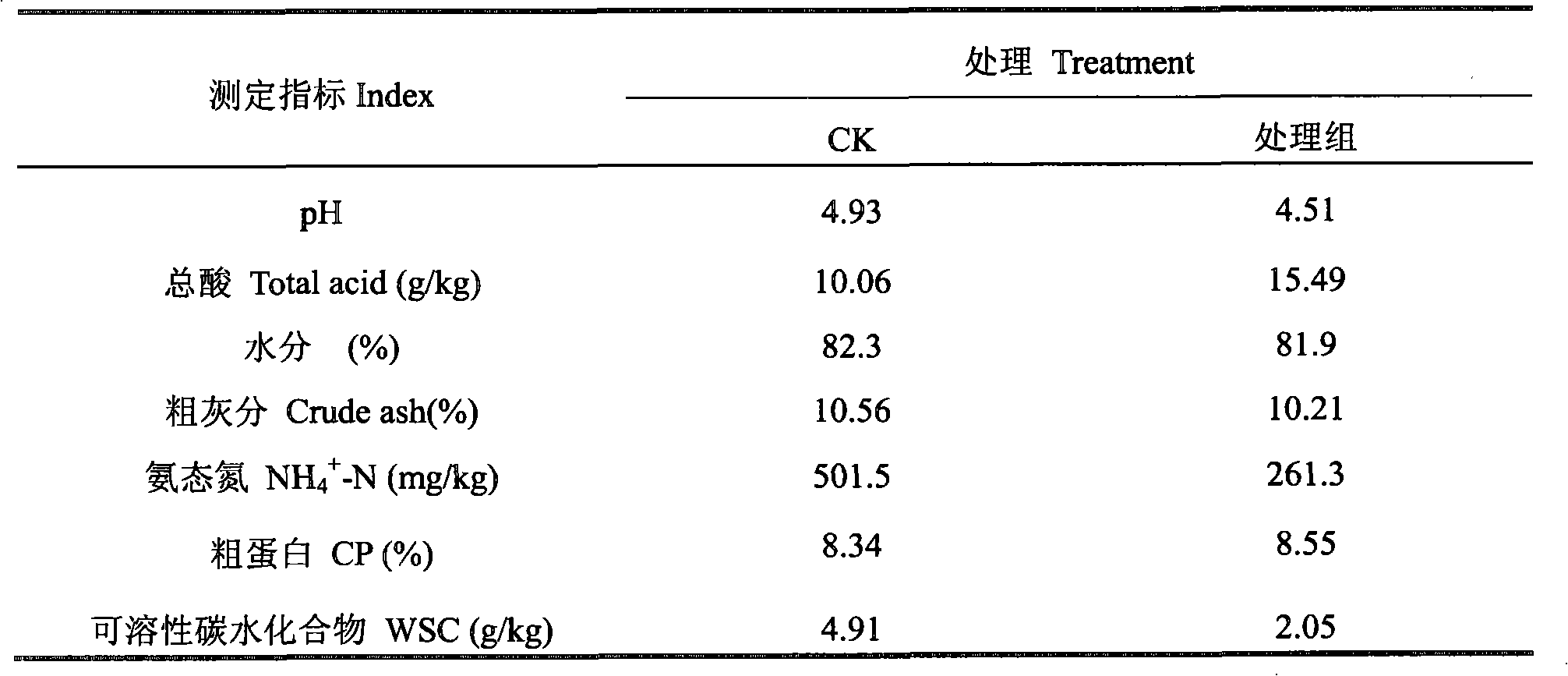

[0020] Embodiment 2: fully mix with the apple pomace according to the following bacterium formula: use fresh corn stalks without cobs as the silage raw material, add Lactobacillus plantarum respectively (the number of bacteria is 5.0 × 10 9 ~1.0×10 10 cfu / mL) and Pediococcus pentosacea (the number of bacteria is 5.0×10 9 ~1.0×10 10 cfu / mL) liquid culture solution 0.1%~0.5%, aroma yeast (the number of bacteria is 2.0×10 8 ~6.0×10 8 cfu / mL) liquid culture solution 0.1%~0.3%, Bacillus cereus (the number of bacteria is 1.0×10 8 ~5.0×10 8 cfu / mL) 0.1% to 0.2% liquid culture solution, fully stirred and mixed, put into a 40*80cm silage bag, squeeze out the air in the bag and seal it, and culture it at room temperature in the dark for 20 to 30 days. The main nutrient changes are shown in Table 2.

[0021] Table 2 Changes in main nutrients

[0022]

Embodiment 3

[0023] Embodiment 3: This embodiment provides a preparation method of microbial additives for silage. Lactobacillus plantarum, Pediococcus pentosaceae, Aroma-producing yeast, Issaccharomyces orientalis and Bacillus cereus are all prepared by liquid culture, wherein plant milk Bacillus and Pediococcus pentosaceae have the same medium, each liter of medium contains: 10g of peptone, 5g of yeast extract, 10g of beef extract, 20g of glucose, 5g of sodium acetate, 2g of diammonium citrate, 1mL of Tween 80, 0.58 of magnesium sulfate g, 0.05g of manganese sulfate, 2g of dipotassium hydrogen phosphate, 20g of agar, 1L of distilled water; the culture medium of Aroma-producing yeast and Issaccharomyces orientalis is the same, and each liter of liquid medium contains: yeast powder 2g, glucose 30g, dipotassium hydrogen phosphate 1.0 grams, 0.5 grams of magnesium sulfate, 2.0 grams of ammonium sulfate, 1 L of distilled water; each liter of Bacillus cereus liquid medium contains: 3 g of beef ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com