Ordered structure catalyst for hydrogenation of oxalic ester for preparing ethylene glycol and preparation method thereof

A regular structure and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the constraints on the industrialization process of oxalate hydrogenation to ethylene glycol technology, increase the particle size of particle catalysts, Catalyst overheating side reactions and other problems, to achieve the effect of shortening the internal diffusion path, increasing the effective contact area, and reducing bed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

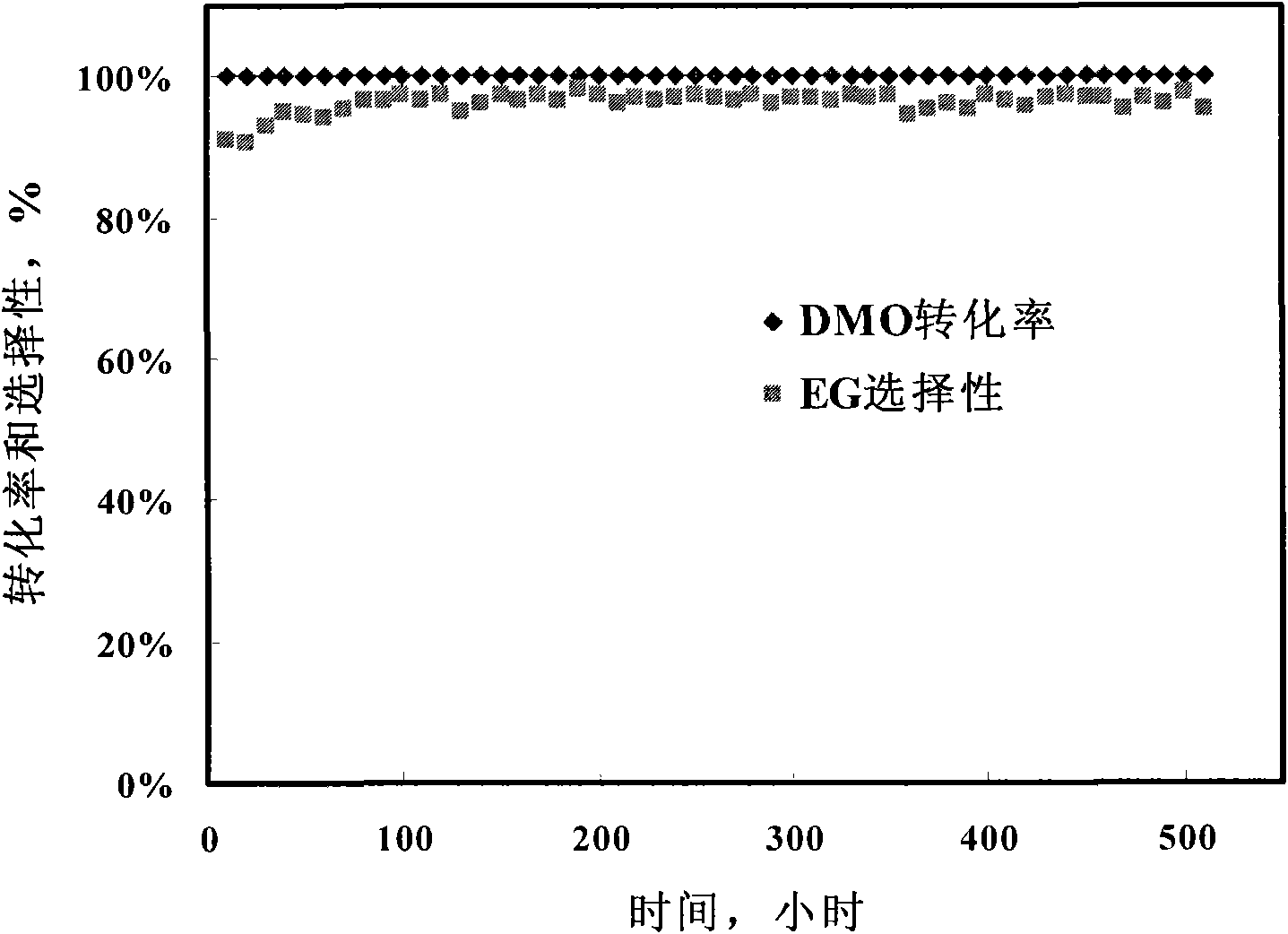

Examples

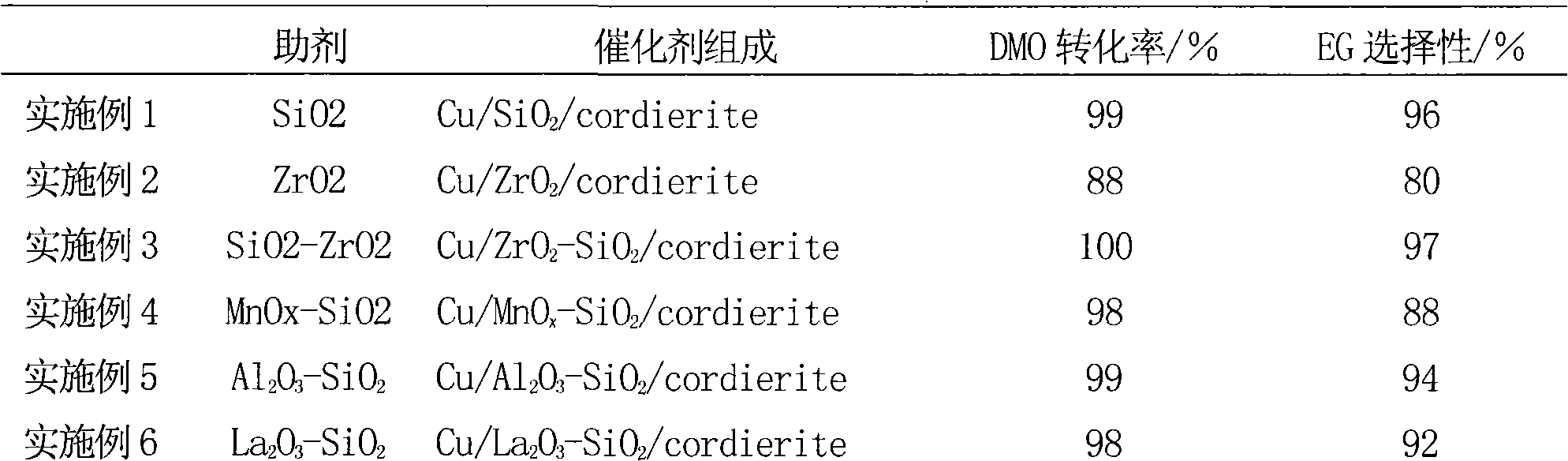

Embodiment 1

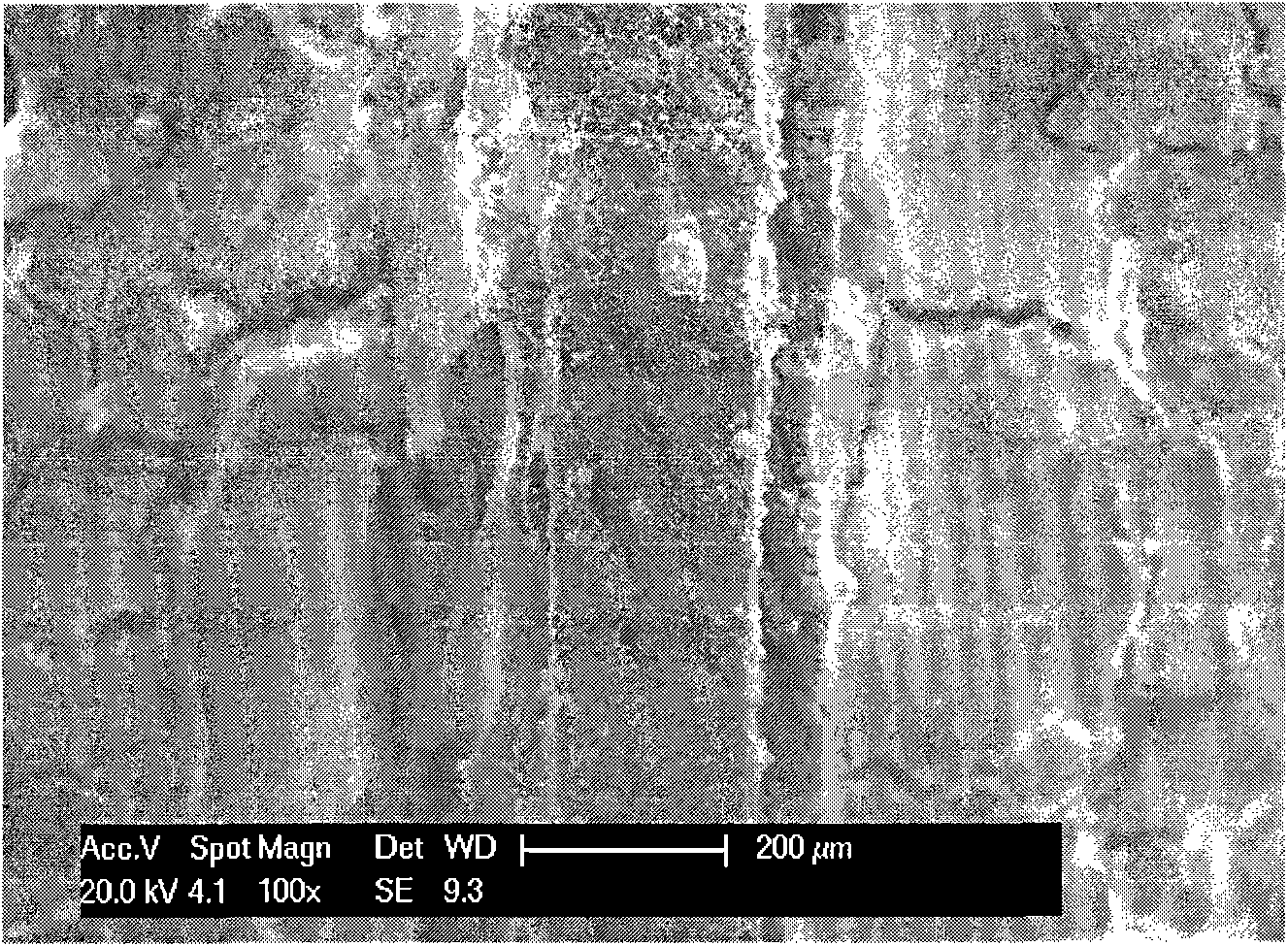

[0045] Structured Catalyst Preparation

[0046] Weigh 15.5g of copper nitrate pentahydrate and dissolve it in 150ml of water, slowly add 52ml of 25wt.% ammonia water to dissolve it and mix well. 45ml of 30wt.% silica sol was added dropwise to the solution, and after the dropwise addition was completed, it was aged for 4 hours under stirring. Then heat up to 95°C to precipitate copper and silicon oxide. The precipitate was filtered, washed three times with deionized water, dried at 120°C for 12 hours, and calcined at 450°C for 4 hours to form a copper content of 20wt.%, SiO 2 80wt.% Cu / SiO 2 Catalyst raw powder.

[0047] Part of the above Cu / SiO 2 The raw catalyst powder is extruded and sieved into 40-60 mesh, and then 8.0g of the formed Cu / SiO is taken 2 Catalyst particles, 8.0gCu / SiO 2 Catalyst raw powder and 0.5 g of pseudo-boehmite were placed in a ball mill jar, 50 ml of water was added, and ball milled (planetary ball mill XQM-2L, Nanjing Sunco) at a speed of 200 rp...

Embodiment 2

[0052] Weighing 30g Zr(NO 3 ) 4 ·5H 2 O was added to a 200ml beaker, and 100ml of 70% nitric acid was added to dissolve it and adjust the Zr(NO 3 ) 4 The concentration is 2M. Under the stirring state, ammonia water was slowly added dropwise in the solution until the pH was 4.0-5.0, at this time Zr(NO 3 ) 4 The solution is transformed into a translucent zirconium sol, and deionized water is added to adjust the concentration of the zirconium sol to 1 mol / L, and then aged under air atmosphere for 24-48 hours with stirring.

[0053] In addition to adopting 127ml of the above zirconium sol instead of silica sol to prepare copper content of 20wt.%, ZrO 2 80wt.% Cu / ZrO 2 Catalyst former powder and prepare catalyst slurry with it, all the other are with embodiment 1, make the Cu / ZrO that coating weight is 20% of honeycomb carrier 2 / cordierite conformation catalyst.

[0054] The volumetric space velocity of dimethyl oxalate is 0.6h -1 In addition, the catalyst evaluation met...

Embodiment 3

[0056] Weigh 15.25g of copper nitrate pentahydrate dissolved in 120ml of water, slowly add 54.6g of NaHCO 3 Let it dissolve and mix well. 30wt.% silica sol and zirconium colloid prepared in Example 2 were added dropwise to the solution. The volumes of zirconium colloid and silica sol were 16ml and 39ml respectively. After the addition was completed, the mixture was aged for 4 hours under stirring. The temperature is then raised to 95°C to precipitate copper, silica and zirconia. The precipitate was filtered, washed 3 times with deionized water, dried at 120 degrees for 12 hours, and roasted at 450 degrees for 4 hours to form a copper content of 20wt.%, ZrO 2 10wt.% Cu / ZrO 2 -SiO 2 The raw catalyst powder is ready for use.

[0057] Part of the above Cu / ZrO 2 / SiO 2 The raw catalyst powder is extruded and sieved into 40-60 mesh, and then 15.0g of the formed Cu / ZrO 2 -SiO 2 Catalyst particles, 1.0g Cu / ZrO 2 -SiO 2 The raw catalyst powder and 0.5 g of pseudo-boehmite wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com