Ni-Zn ferrite/SiO2 composite nano-fiber and preparation method thereof

A composite nanofiber, nanofiber technology, applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problems of thin, light, wide, strong, low ferrite saturation magnetization, and wave absorption frequency narrow and other problems, to achieve the effect of easy control of the reaction process, controllable electromagnetic performance, and low duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

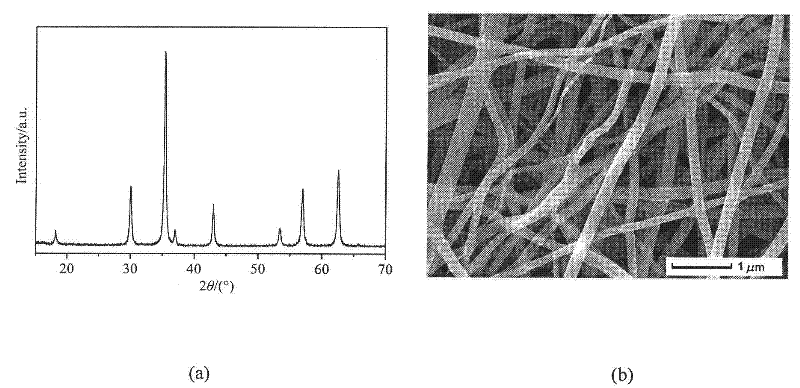

[0027] Example 1 [(Ni 0.5 Zn 0.5 Fe 2 o 4 ) 97.5 (SiO 2 ) 2.5 Composite nanofibers, synthesis temperature 900°C]

[0028] Step 1: Dissolve 0.9407g polyvinylpyrrolidone (PVP) in 9.0593g absolute ethanol (CH 3 CH 2 OH, analytically pure) and 4.0000g of deionized water in a mixed solvent, and magnetic stirring at room temperature for about 1h to completely dissolve the PVP. Then weigh 1.2928g iron nitrate (Fe(NO 3 ) 3 9H 2 O, analytically pure), 0.1990g nickel acetate (Ni(CH 3 COO) 2 4H 2 O, analytically pure), 0.1756g zinc acetate (Zn(CH 3 COO) 2 2H 2 (2, analytically pure) and 0.0338g tetraethyl orthosilicate (TEOS, analytically pure) were added in the above-mentioned PVP solution, then continued magnetic stirring for about 20h to obtain a homogeneous precursor solution, wherein the concentration of PVP was 6wt%. The concentration of the metal salt was 10.6 wt%.

[0029] Step 2: Control the relative humidity and temperature in the room below 65% and within the...

Embodiment 2

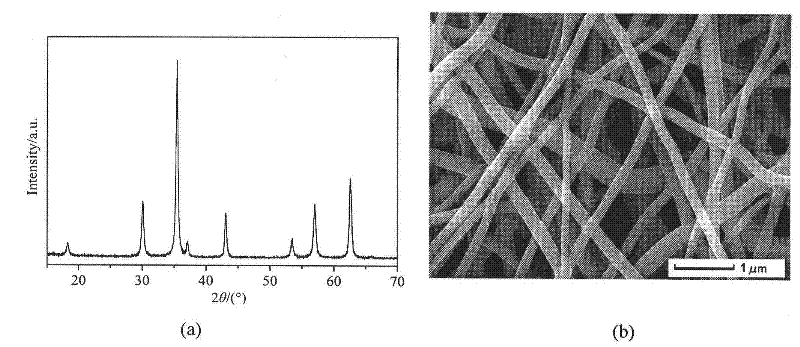

[0031] Embodiment 2 [(Ni 0.5 Zn 0.5 Fe 2 o 4 ) 95 (SiO 2 ) 5 Composite nanofibers, synthesis temperature 900°C]

[0032] Step 1: Dissolve 1.8000g of PVP in a mixed solvent composed of 8.7313g of absolute ethanol and 4.0000g of deionized water, and stir magnetically at room temperature for about 1 hour to completely dissolve the PVP. Then weigh 0.3489g ferric nitrate, 0.0537g nickel acetate, 00474g zinc acetate and 0.0187g tetraethyl orthosilicate according to the chemical composition of the target fiber and add them to the above PVP solution, and then continue magnetic stirring for about 20h to obtain a homogeneous precursor Body solution, wherein the concentration of PVP is 12wt%, and the concentration of metal salt is 3wt%.

[0033] Step 2 is basically the same as Step 2 of Example 1, except that the spinning electric field intensity is adjusted to 1.5kV / cm.

[0034] Step 3: Place the dried precursor fiber in a programmable electric furnace, raise the temperature to ...

Embodiment 3

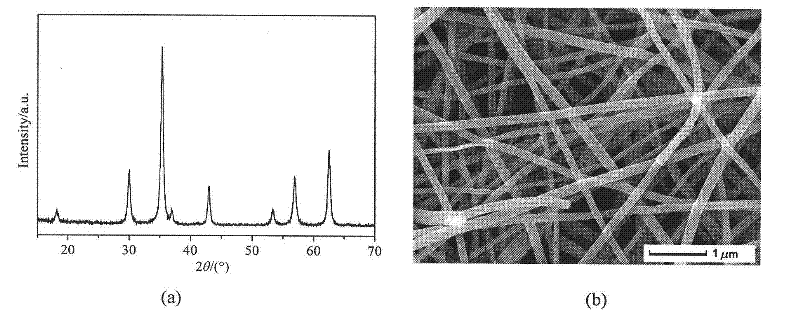

[0035] Embodiment 3 [(Ni 0.5 Zn 0.5 Fe 2 o 4 ) 90 (SiO 2 ) 10 Composite nanofibers, the synthesis temperature is 900°C]

[0036] Step 1: Dissolve 0.9488g of PVP in a mixed solvent composed of 9.0512g of absolute ethanol and 4.0000g of deionized water, and magnetically stir at room temperature for about 1 hour to completely dissolve the PVP. Then weigh 1.2928g ferric nitrate, 0.1990g nickel acetate, 0.1756g zinc acetate and 0.1466g tetraethyl orthosilicate according to the chemical composition of the target fiber and add them to the above PVP solution, then continue magnetic stirring for about 20h to obtain a uniform composition. Precursor solution, wherein the concentration of PVP is 6wt%, and the concentration of metal salt is 10.5wt%.

[0037] Step 2 is the same as Step 2 of Example 1.

[0038] Step 3: Place the dried precursor fiber in a programmable electric furnace, raise the temperature to 900°C at a rate of 3°C / min and keep it warm for 2 hours. After cooling to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com