Corynebacterium glutamicum and method for preparing L-ornithine and salts thereof by using same

A technology of Corynebacterium glutamicum and ornithine, applied in the field of fermentation engineering, can solve the problems of low yield, many reaction steps, difficulty in large-scale production, etc., and achieves simple fermentation process, extensive culture conditions, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Slant medium: 1g glucose, 10g peptone, 5g beef extract, 5g NaCl, 20g agar, add water to 1000ml, pH 7.0-7.2, sterilize at 0.1Mpa at 121°C for 20min.

[0036] Shake flask medium: glucose 25g, yeast extract 10g, (NH 4 ) 2 SO 4 15g, MgSO 4 ·7H 2 O 2.5g, KH 2 PO 4 1g, K 2 HPO 4 ·3H 2 O 0.5g, NaH 2 PO 4 2H 2 O 0.5g, CaCO 3 10g, add water to 1000ml, pH7.6-7.8, sterilize at 0.1Mpa at 121℃ for 10min.

[0037] Fermentation medium: glucose 60g, yeast extract 30g, (NH 4 ) 2 SO 4 50g, MgSO 4 ·7H 2 O 2.50g, KH 2 PO 4 1g, K 2 HPO 4 ·3H 2 O 0.5g, Na 2 HPO 4 2H 2 O 0.50g, CaCO 3 10g, FeSO 4 ·7H 2 O 36.6mg / L, MnSO 4 ·H 2 O 22.38 mg, ZnSO 4 ·7H 2 O 17.8mg, Biotin (biotin) 0.05mg, V B1 0.05mg, add water to 1000ml, pH7.6-7.8, sterilize at 0.1Mpa at 121℃ for 10min.

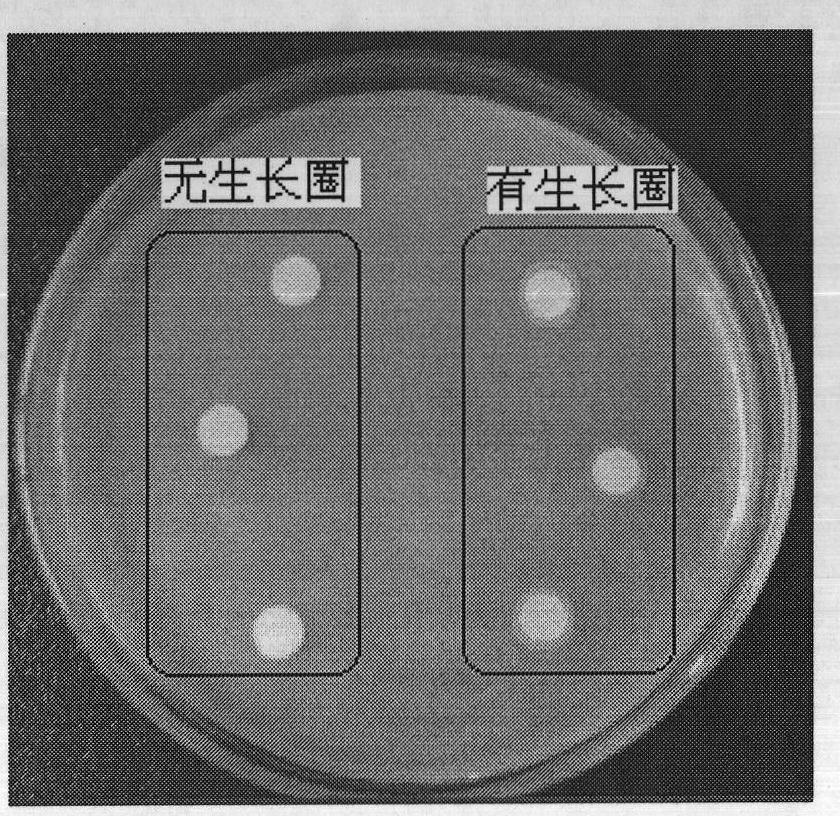

[0038] Corynebacterium glutamicum 1006 with the preservation number CGMCC No.3663 was cultured statically on a slant medium at 30°C for 18-20 hours, and then a ring of well-grown activated strai...

Embodiment 2

[0040] Glucose 180g, yeast extract 90g, (NH 4 ) 2 SO 4 150g, MgSO 4 ·7H 2 O 7.5g, KH 2 PO 4 3g,K 2 HPO 4 ·3H 2 O 1.5g, Na 2 HPO 4 2H 2 O 1.5g, CaCO 3 30g, FeSO 4 ·7H 2 O 0.1g, MnSO 4 ·H 2 O0.067g, ZnSO 4 ·7H 2 O 0.053g, Biotin 0.15mg, V B1 0.15mg, adjust the pH to 7.6-7.8, dilute to 3L with water, put into a 5L automatic glass stirring fermenter, and steam sterilize at 121°C for 10min.

[0041] The activated Corynebacterium glutamicum 1006 with the preservation number of CGMCC No.3663 was cultivated at 30° C. for 11 hours with a seed medium to obtain a seed liquid, and 120 mL of the seed liquid was inserted into a cooled 5 L fermenter and cultivated at 28° C. ( Ventilation ratio 1: 0.7vvm, stirring speed is 220r / min), along with the increase of culture time, L-ornithine constantly increases, and to 72h, containing L-ornithine in the fermented liquid is 45g / L.

Embodiment 3

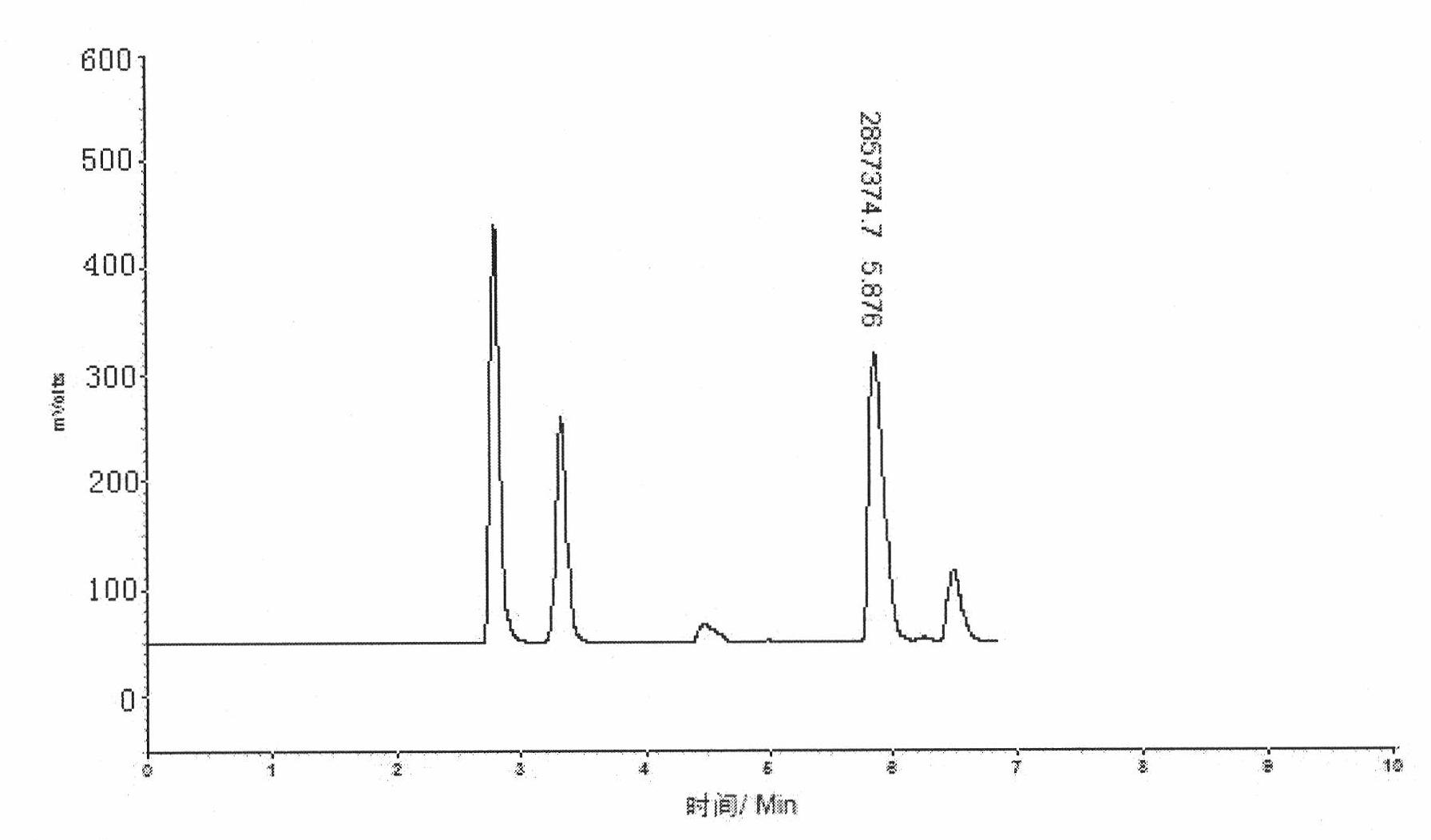

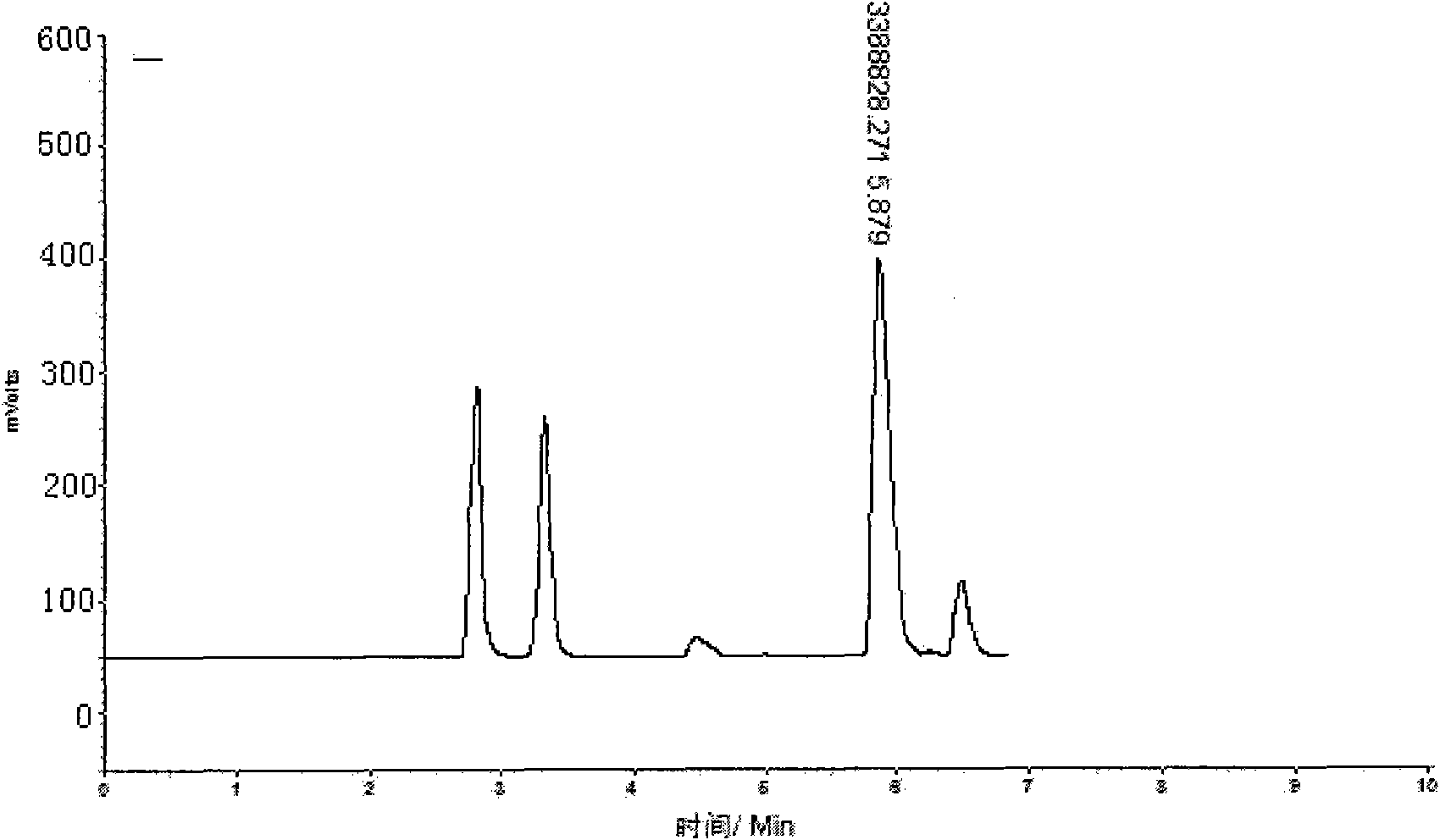

[0043] Same as Example 2, the process control pH value (ceramic membrane operating pH) is at 6.8 ± 0.05, and the final fermentation broth adopts a titanium dioxide ceramic membrane with a molecular weight cut-off of 50,000 Daltons, with an operating pressure difference of 0.22MPa, a temperature of 58°C, and a flux of 192L·m -2 h -1 , effectively remove the bacteria; the clear liquid is adsorbed by JK006 cation exchange resin, 0.5mol / L ammonia water is eluted, pure water is washed, the collected liquid is concentrated to remove ammonia, and activated carbon is decolorized; the decolorized liquid is adjusted to pH 4.8 with concentrated hydrochloric acid, and the temperature is 20 ℃, the stirring speed is 200r / min, crystallization with ethanol solution, the crystallization time is 6h, and the crystallization of L-ornithine hydrochloride is obtained, the yield is 88.1%, and the purity is 98.7%. (Calculation of yield: before and after extraction and separation, use HPLC-ELSD to de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com