Method for preparing thallium-doped caesium iodide (CsI:T1) film

The technology of thallium cesium iodide and thin film is applied in the field of preparation of thallium-doped cesium iodide thin film, which can solve the problems of large volume, difficult integration, and not portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

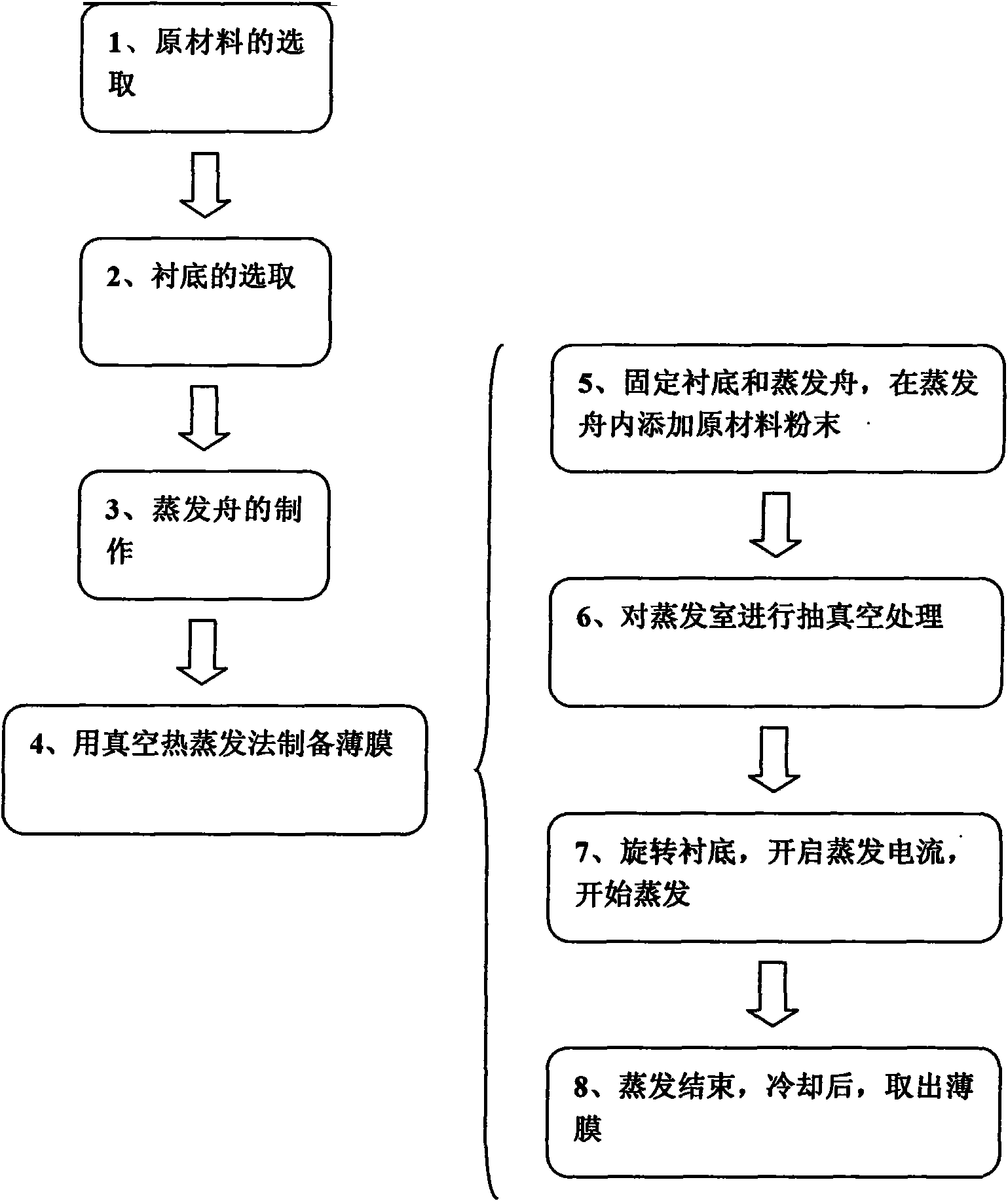

[0010] specific implementation plan

[0011] (1) Selection of raw materials

[0012] The raw materials used in the present invention are CsI and TlI crystals with a purity of 99.99%. Before coating, the two crystals are mixed together, and the molar ratio of the two in the mixed crystal is roughly 1000 / (0.5~5.0)

[0013] (2) Selection of substrate

[0014] P-type single crystal Si, n-type single crystal Si, glass material and P-type single crystal silicon coated with silicon dioxide film are selected as substrates.

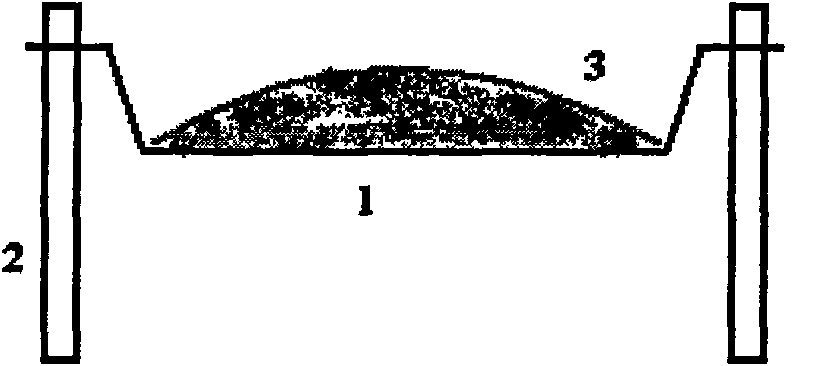

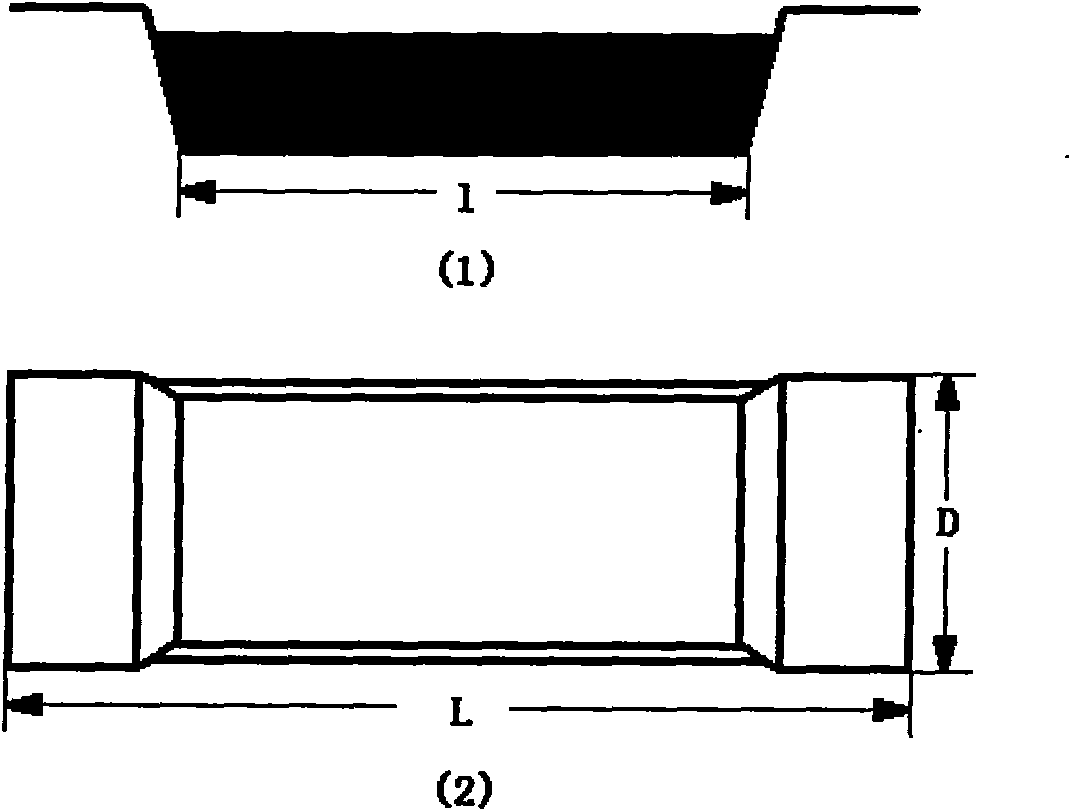

[0015] (3) Production of evaporation boat

[0016] Metal molybdenum is selected as the material to make a boat-shaped container, which is fixed on the evaporation electrode.

[0017] (4) thermal evaporation

[0018] The thermal evaporation system uses tungsten as a helical resistance heating source to perform resistance heating on the substrate. The substrate to be coated is placed on the shelf, and a molybdenum boat is used as the evaporation source. The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com